Miniature fuse

A fuse, a small technology, applied in the direction of electrical components, circuits, fuse manufacturing, etc., can solve the problems of unfavorable breaking capacity, excessive metal vapor, poor fusing capacity, etc., to achieve excellent fusing capacity, reduce arcing, and good breaking capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

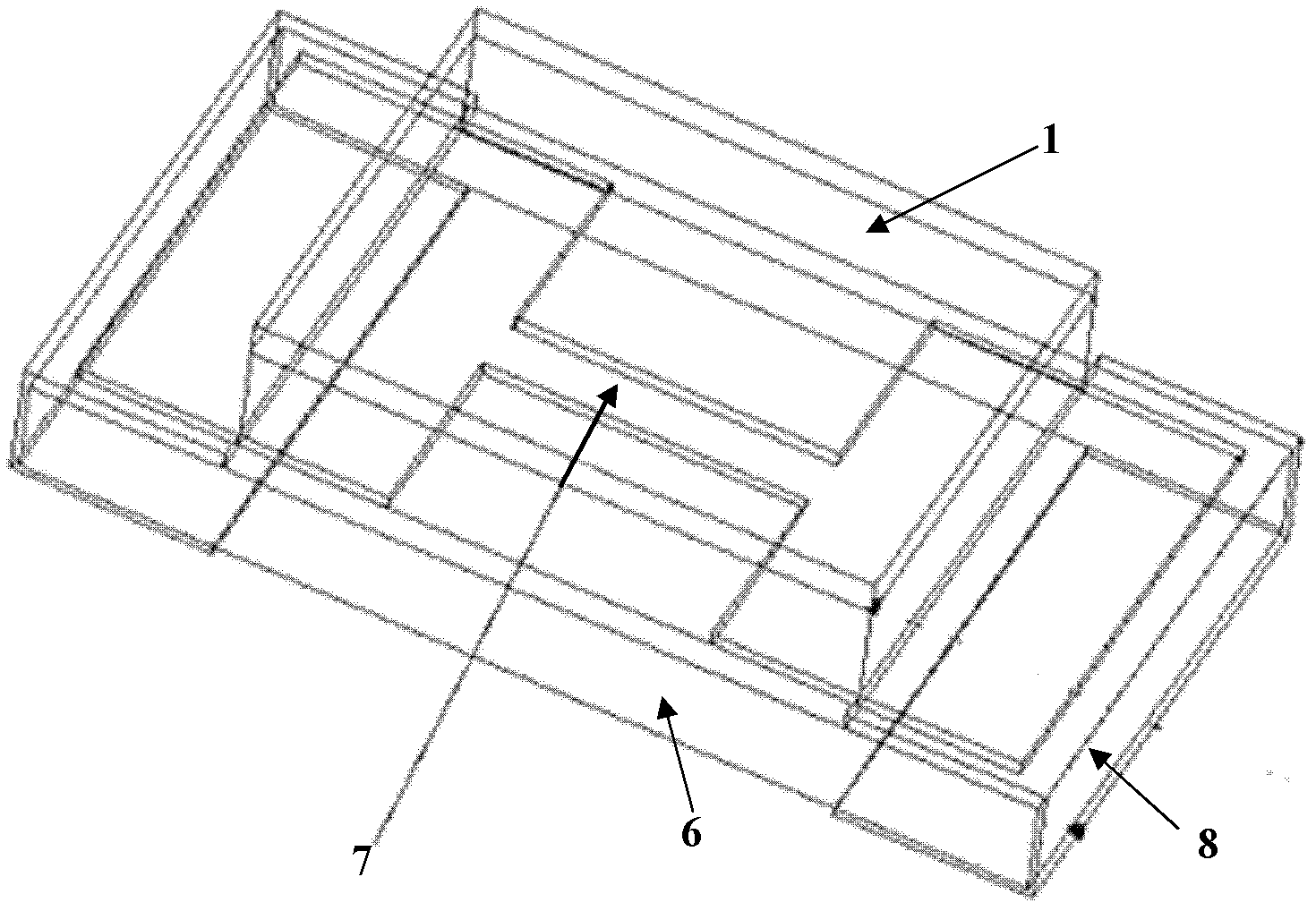

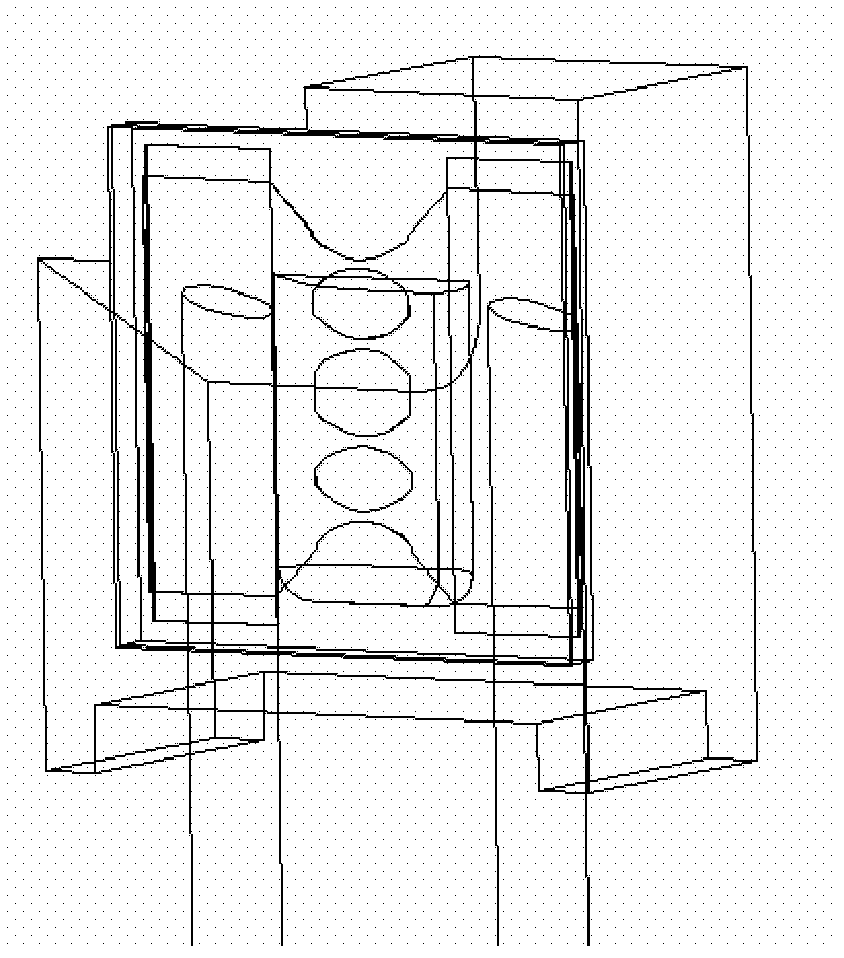

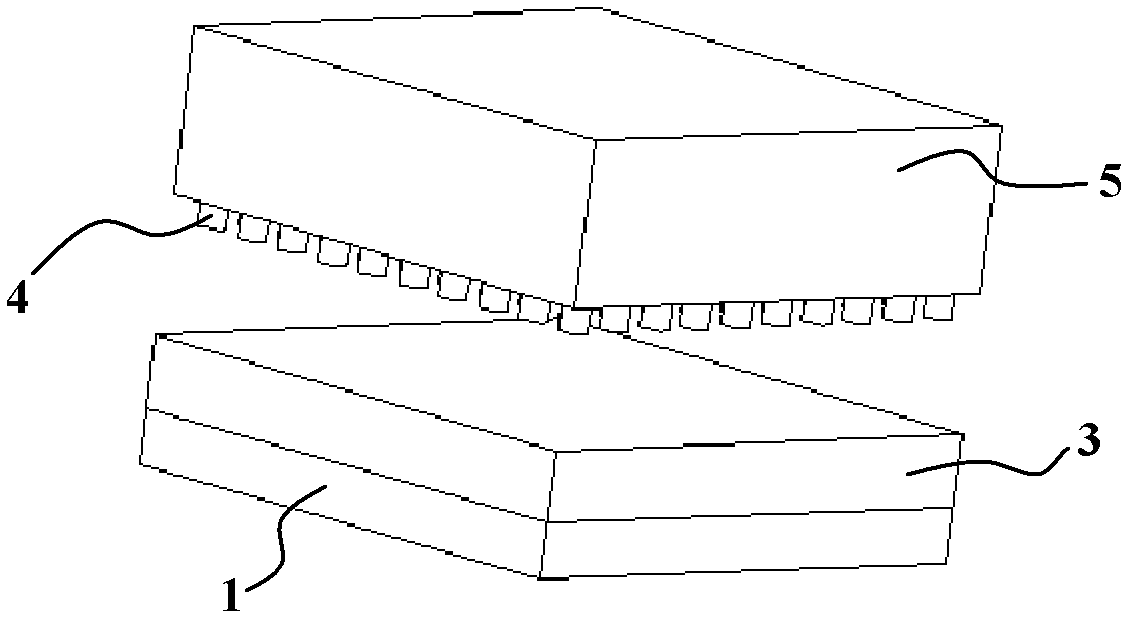

[0026] Embodiment: A small fuse, as shown in the accompanying drawings, consists of two terminals 8, a substrate 6, a melt 7 and an arc-extinguishing glass layer, the melt is located on the surface of the substrate, and the two terminals 8 are respectively connected to Both ends of the melt are electrically connected, and the arc-extinguishing glass layer covers the surface of the melt. The arc-extinguishing glass layer is an arc-extinguishing glass sheet. The arc-extinguishing glass sheet 1 is composed of lead borosilicate glass. The arc-extinguishing glass The surface of the sheet 1 in contact with the melt has several micro-nano holes 2, and the melt is formed by brushing a conductive paste containing spherical or nearly spherical metal particles through a screen. The conductive paste is composed of a glass phase, an organic carrier It is composed of the metal particle; the metal particle is 80-100 nanometers, and the central area of the metal particle has a hollow area. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com