Temperature fuse with resistor and battery protection circuit

A resistance temperature and fuse technology, applied in the field of resistance temperature fuses, can solve the problem of narrow operating power range and achieve the effect of ensuring miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

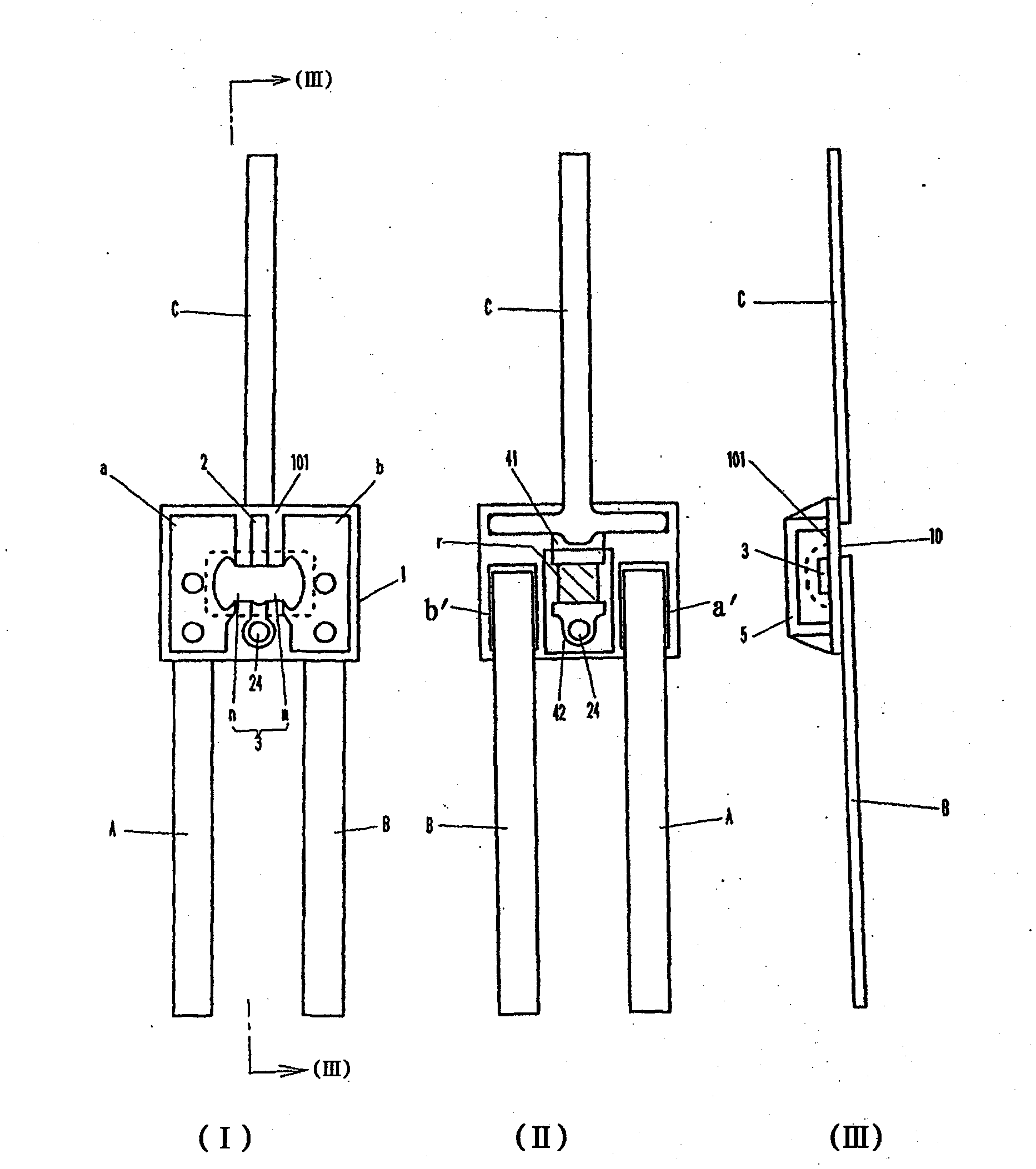

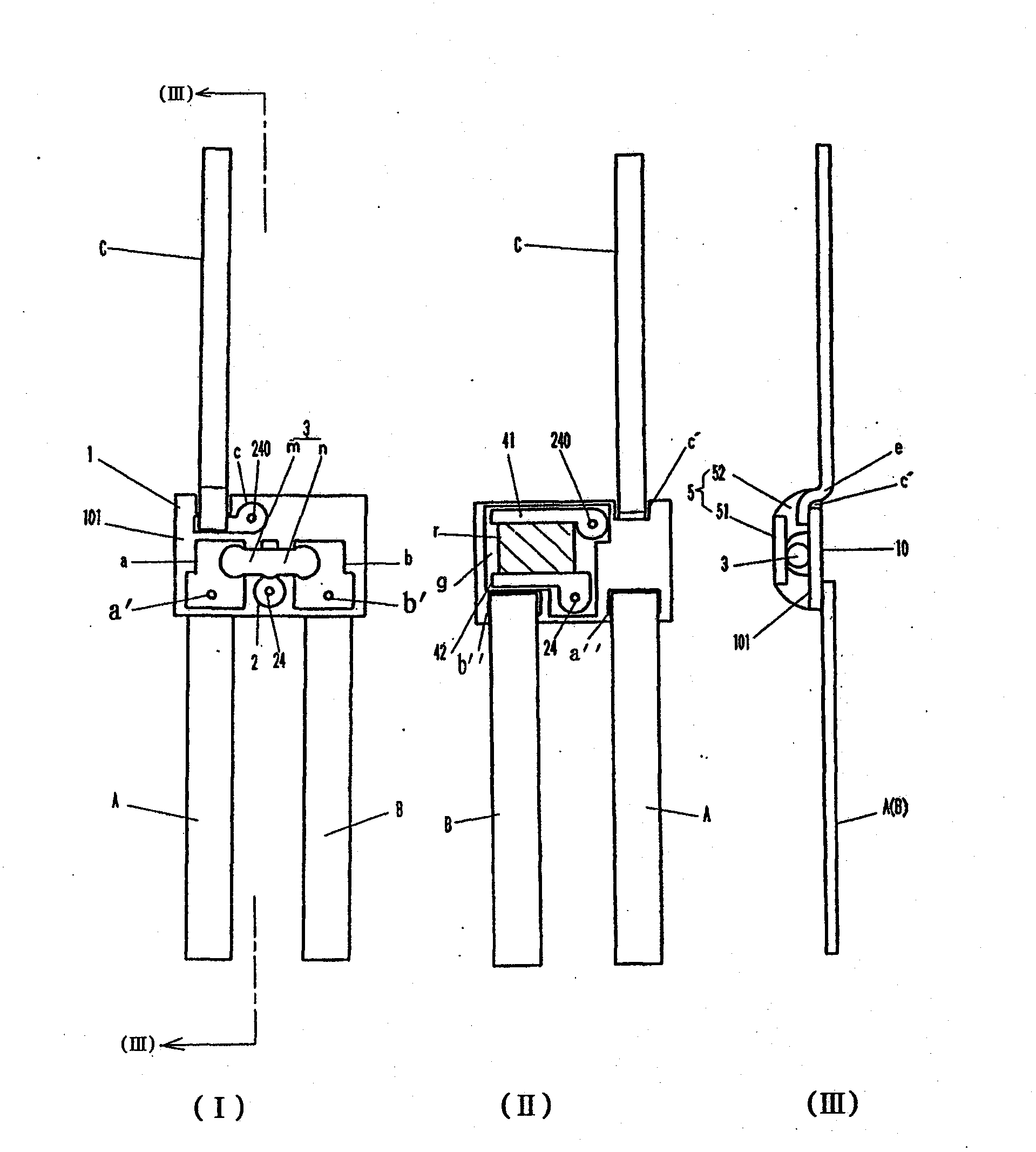

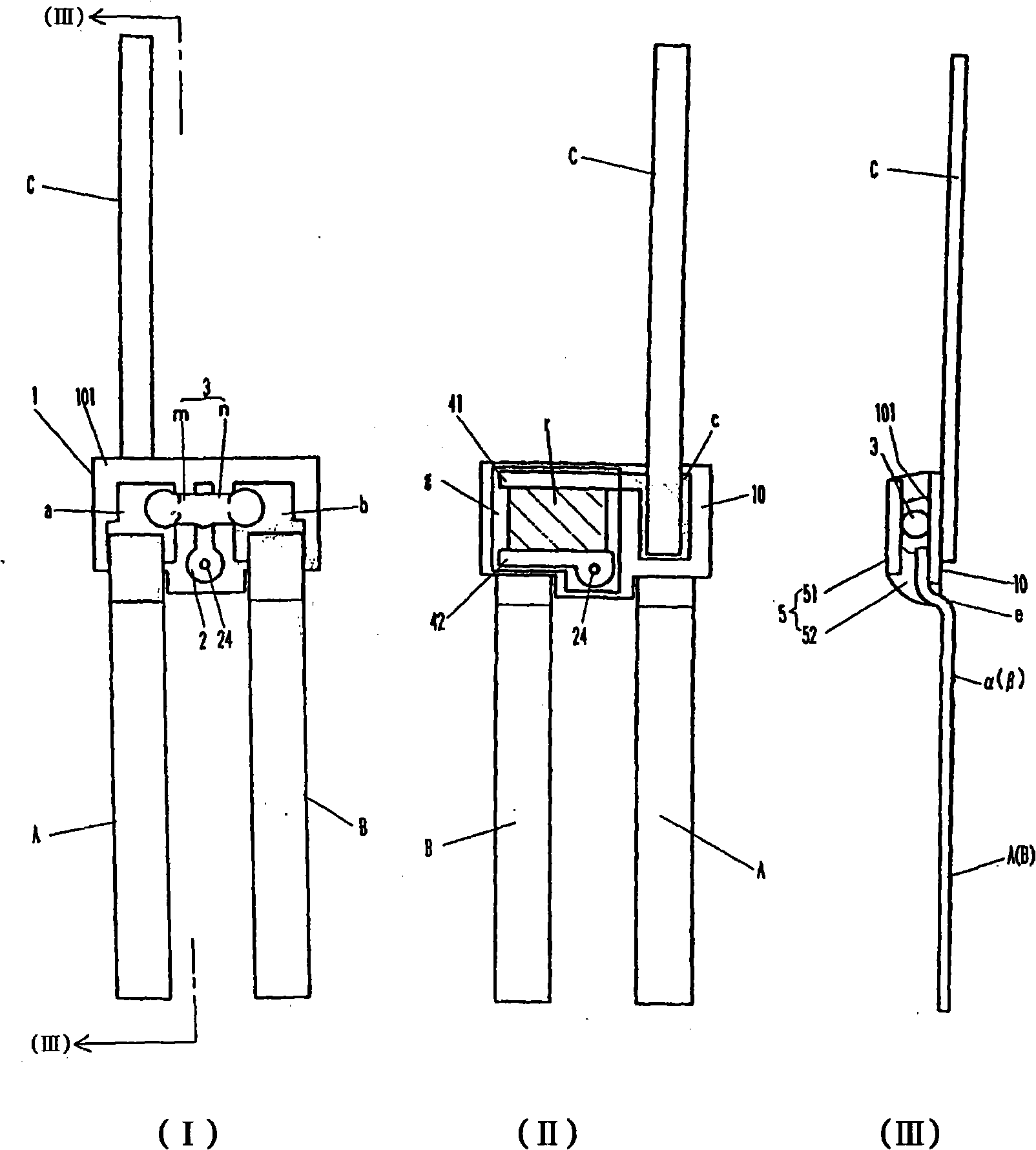

[0044] Below, while referring to the attached Figure 1 Next, an embodiment of the thermal fuse with resistance according to the present invention will be described.

[0045] figure 1 Indicates an embodiment related to technical scheme 1, figure 1 (I) is a plan view omitting an insulating sealant, figure 1 (II) is the rear view, figure 1 (III) Yes figure 1 Section III-III in (I).

[0046] exist figure 1 In (I), 1 is an insulating substrate such as a ceramic plate having good heat resistance and thermal conductivity. a and b are membrane electrodes formed on both sides of one surface of an insulating substrate, and 2 is an intermediate electrode formed by printing and firing a conductive paste such as silver paste. 3 is a fuse element, arranged across the membrane electrodes a, b on both sides and the middle membrane electrode 2, and welded at the intersection with the membrane electrodes a, b, 2. The fuse element 3 is divided into parts n and m sandwiching the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com