Nano heat-insulating PVB intermediate film for laminated glass and preparation method thereof

A technology of nano heat insulation and laminated glass, applied in chemical instruments and methods, glass/slag layered products, coatings, etc., can solve the problem of unsatisfactory anti-oxidation and anti-yellowing performance of PVB interlayer film, which affects the energy-saving performance of laminated glass , does not have heat insulation function and other problems, achieves excellent anti-oxidation performance and anti-yellowing performance, simple and reasonable preparation method, and good use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

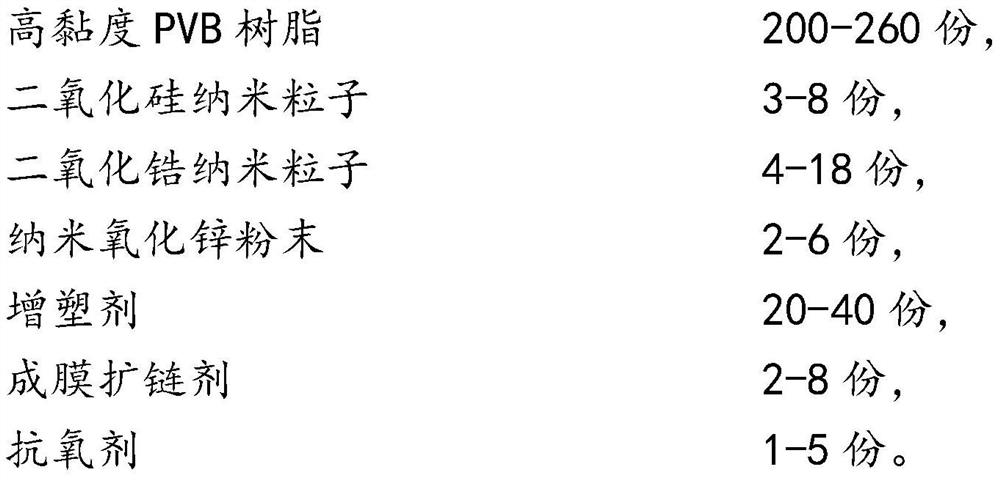

[0025] This embodiment discloses a nano thermal insulation PVB intermediate film for laminated glass, which includes a modified PVB base film and a thermal insulation coating compounded on at least one side of the modified PVB base film; the modified PVB The base film includes the following raw materials measured in parts by mass:

[0026]

[0027]

[0028] Wherein, the film-forming chain extender is an ester formed by a dibasic acid and an alcohol. The thickness of the modified PVB base film is 0.35-0.80 mm. The thermal insulation coating is coated on the outer surface or both inner and outer surfaces of the modified PVB base film. The thermal insulation coating is formed by coating nano thermal insulation PVB paint.

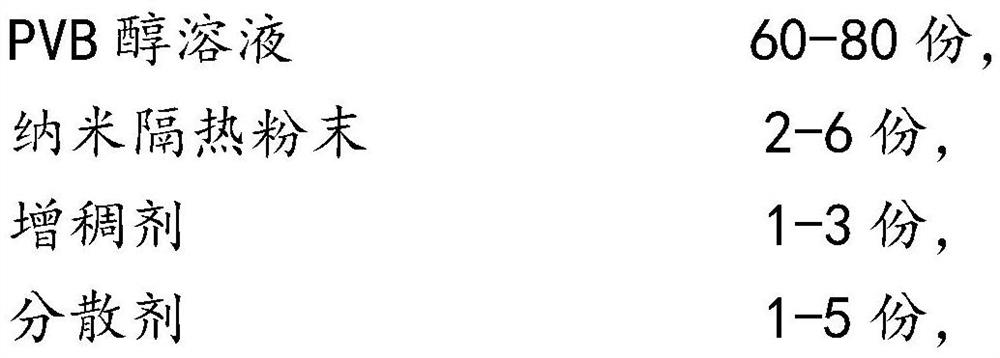

[0029] Specifically, the thermal insulation coating adopts the nano thermal insulation PVB coating and includes the following raw materials measured in parts by mass:

[0030]

[0031] Among them, the nano thermal insulation powder is nano tin oxide antimony powder...

Embodiment 2

[0037] This embodiment discloses a nano thermal insulation PVB intermediate film for laminated glass, which includes a modified PVB base film and a thermal insulation coating compounded on at least one side of the modified PVB base film; the modified PVB The base film includes the following raw materials measured in parts by mass:

[0038]

[0039] Wherein, the film-forming chain extender is an ester formed by a dibasic acid and an alcohol. The thickness of the modified PVB base film is 0.35-0.80 mm. The thermal insulation coating is coated on the outer surface or both inner and outer surfaces of the modified PVB base film. The thermal insulation coating is formed by coating nano thermal insulation PVB paint.

[0040] Specifically, the thermal insulation coating adopts the nano thermal insulation PVB coating and includes the following raw materials measured in parts by mass:

[0041]

[0042] Among them, the nano heat insulation powder is a mixed powder of nano tin oxide antimony ...

Embodiment 3

[0048] This embodiment discloses a nano thermal insulation PVB intermediate film for laminated glass, which includes a modified PVB base film and a thermal insulation coating compounded on at least one side of the modified PVB base film; the modified PVB The base film includes the following raw materials measured in parts by mass:

[0049]

[0050] Wherein, the film-forming chain extender is an ester formed by a dibasic acid and an alcohol. The thickness of the modified PVB base film is 0.35-0.80 mm. The thermal insulation coating is coated on the outer surface or both inner and outer surfaces of the modified PVB base film. The thermal insulation coating is formed by coating nano thermal insulation PVB paint.

[0051] Specifically, the thermal insulation coating adopts the nano thermal insulation PVB coating and includes the following raw materials measured in parts by mass:

[0052]

[0053] Among them, the nano thermal insulation powder is a mixed powder of nano cesium tungsten ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com