Device for utilizing electric heating tantalum expansion-prevention pin for sintering fluorine plastic pipe heat exchanger pipe plate

A technology of fluoroplastic tubes and heat exchangers, which is applied in the field of heat exchanger equipment to achieve the effects of high sealing strength, reduced sintering costs, and no leakage of sintering depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

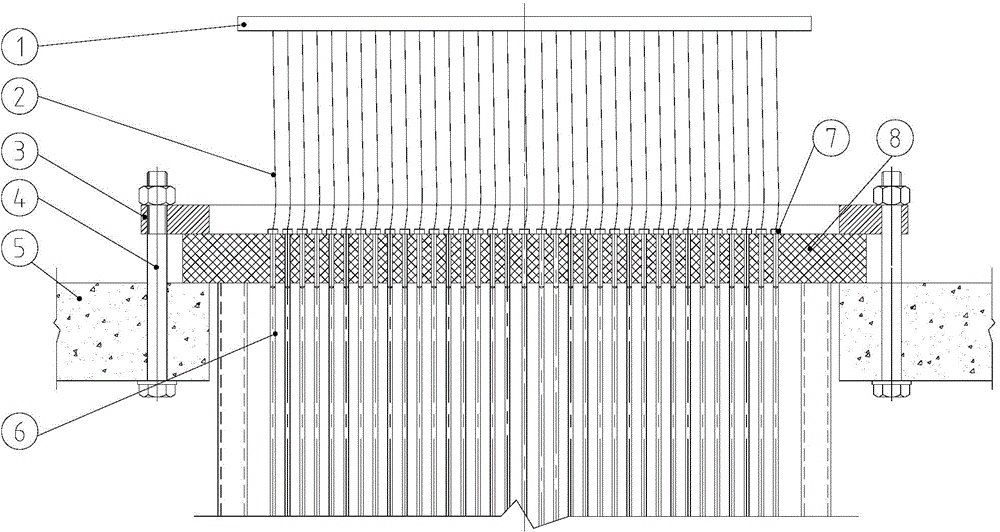

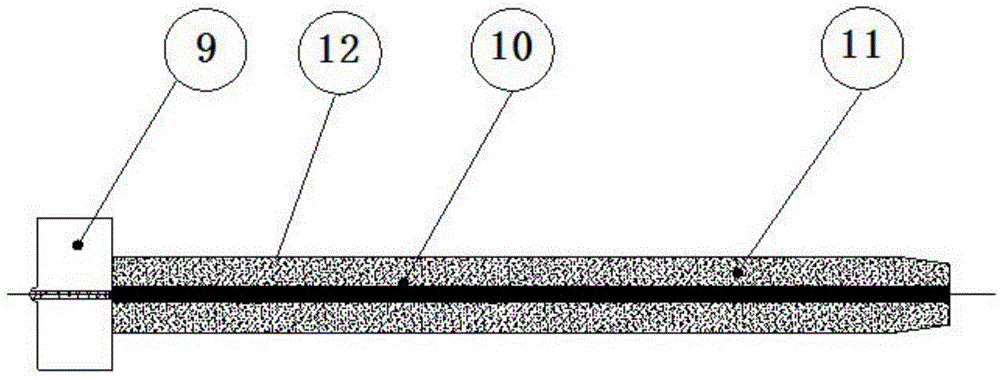

[0015] Concrete structure of the present invention sees figure 1 shown. A device for fusing the tube plate of a fluoroplastic tube heat exchanger by using an electric heating tantalum anti-expansion pin, comprising: a circuit board device (1), a cable (2), a metal pressing plate (3), a locking device (4), and a Mobile chopping board (5), fluoroplastic tube bundle (6), electric heating tantalum tube (7), fluoroplastic tube plate (8). A pair of metal pressing plates (3) are respectively connected with a pair of movable cutting boards (5) below them through locking devices. Both ends of the fluoroplastic tube plate (8) are fixed between the metal pressing plate (3) and the movable chopping board (5), and are connected to the locking device ( 4) Lock tight. Insert the electric heating tantalum tube 7 into the fluoroplastic tube bundle (6), and the fluoroplastic tube bundle (6) is respectively inserted into the fixing holes on the fluoroplastic tube plate (8) and fixed.

[0016...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com