Fuses for Electrical Machinery

An electrical machinery and fuse technology, applied in the field of electric power, can solve the problems of inability to use photovoltaic products, inconvenient installation and disassembly, and inconvenient disassembly, and achieve the effects of increasing ventilation performance, simple structure and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

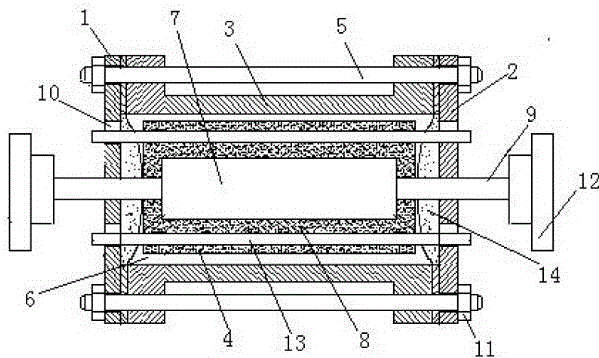

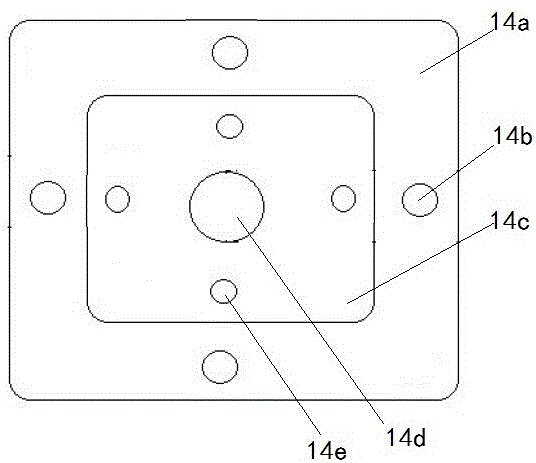

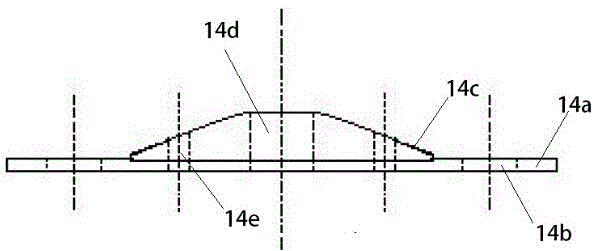

[0015] refer to figure 1 The fuse for electrical machinery shown is characterized in that it includes a left end cover 1, a right end cover 2, a housing 3 and a fuse tube 4, the left end cover 1 is installed on the left side of the housing 3, and the right end cover 2 is installed on the housing 3, the left end cover 1, the shell 3 and the right end cover 2 are provided with a screw 5, and the screw 5 is set through the left end cover 1, the shell 3 and the right end cover 2 in turn; the left end cover 1, the shell 3 and the right end A cavity 6 is formed between the covers 2, the melting tube 4 is installed in the cavity 6, and the melting tube 4 is provided with a melt 7; the left end cover 1 and the right end cover 2 are provided with terminal posts 9, The terminal post 9 is provided with ceramic insulation and heat sink 12, and the terminal post 9 is connected to the fusion pipe 4; the left end cover 1 and the right end cover 2 are provided with ventilation holes 10, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com