Method for correcting electronically programmable fuse wire device

A fuse and electronic technology, used in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to solve problems such as limited programming equipment and pins, limited application scope, and low process yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

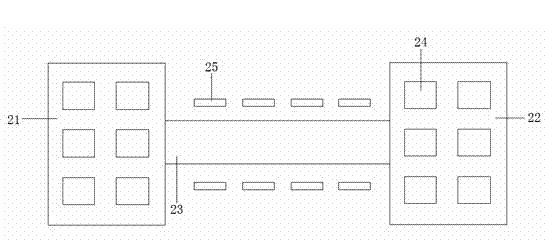

[0020] Such as figure 2 Shown is an electronically programmable fuse device improved by a modification method, including electrodes 21 and 22 and a polysilicon fuse 23 connected between the two electrodes, and 24 is a contact hole on the electrode, and the above-mentioned components are integrated into a on the substrate; wherein, an additional pattern 25 (Sub-resolution Assistant Feature, SRAF) with sub-resolution is added on the substrate on both sides of the polysilicon fuse 23 .

[0021] The so-called sub-resolution additional graphics are a kind of optical proximity correction method (OPC). The principle is to add additional graphics that cannot be resolved by the lithography machine around the normal graphics. These sub-resolution additional graphics cannot be resolved by the lithograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com