Cadmium-oxygen-silver multicomponent electrical contact material and preparation method thereof

A technology of silver cadmium oxide and electric contacts, which is applied in contacts, circuits, electric switches, etc., can solve the problems of difficult processing, high temperature, weak breaking capacity, etc., to reduce environmental pollution and reduce the content of toxic cadmium , The effect of strong breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

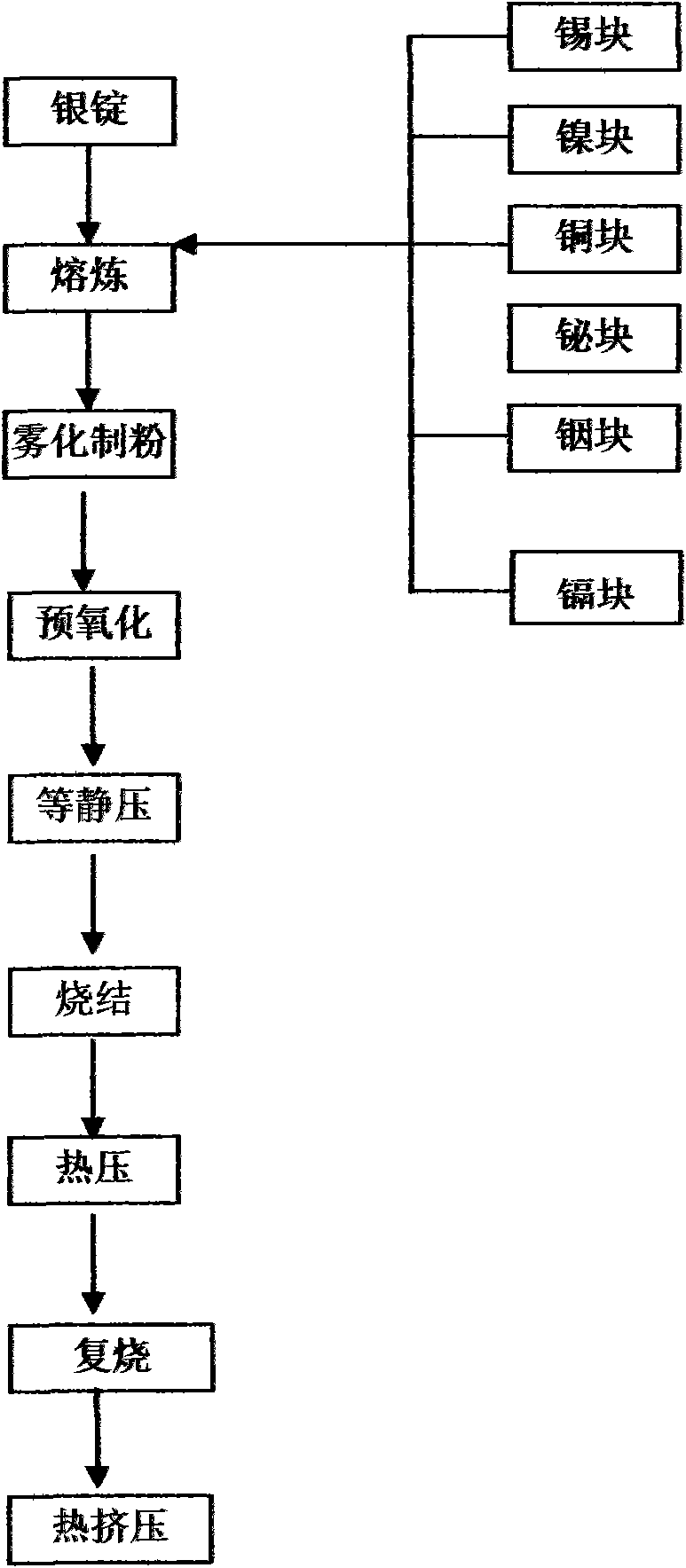

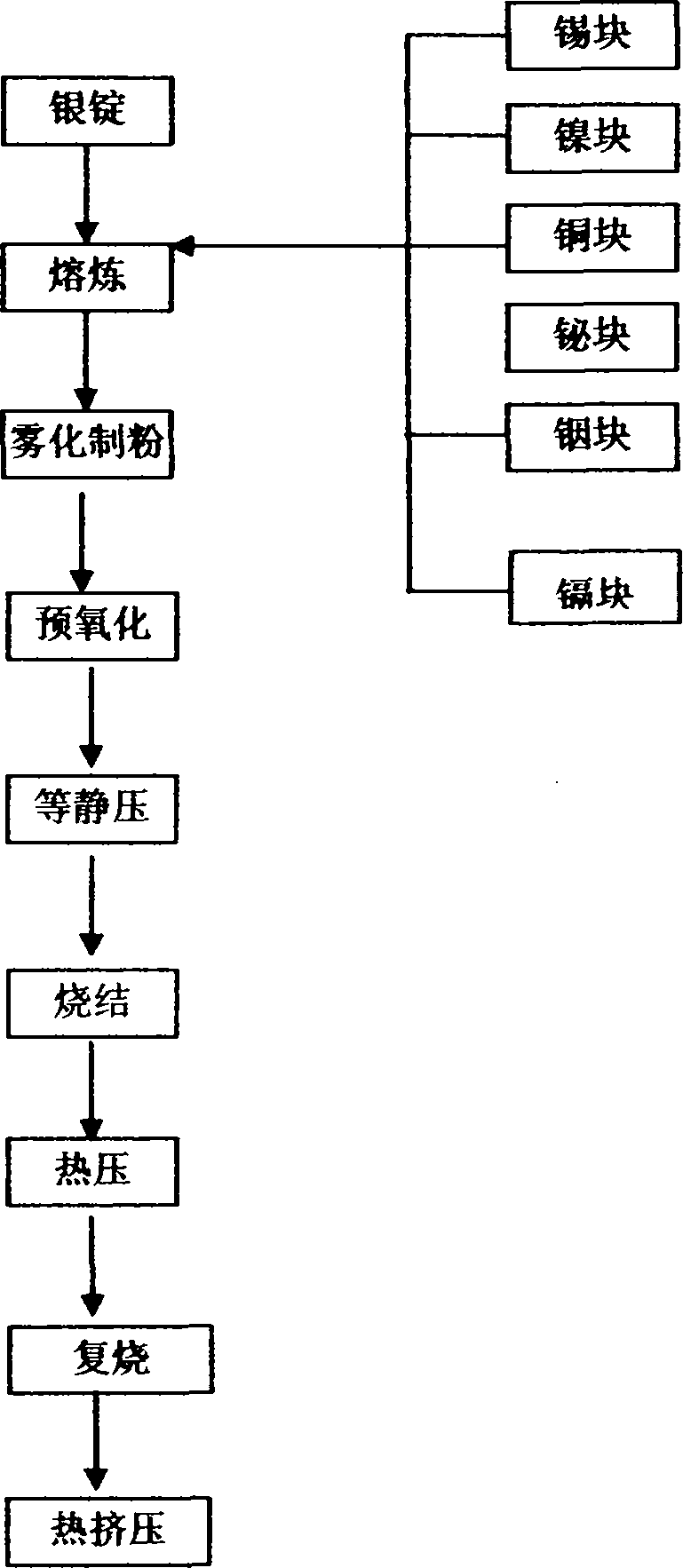

Method used

Image

Examples

Embodiment 1

[0043] In this embodiment, the silver cadmium oxide multi-component reinforced electrical contact material contains components and weight percentages: 5% CdO, 5% SnO 2 , 1% CuO, 0.5% NiO, 0.5% In 2 o 3 , the balance being Ag

[0044] Weigh 17.8Kg silver ingot, put it in a medium frequency induction furnace and melt it, then add 1Kg Cd, 0.8Kg Sn, 0.2kg Cu, 0.1kg Ni, 0.1kg In in sequence, melt and homogenize at 950°C, and mist under 10MPa nitrogen pressure Then put the atomized powder into a high-pressure container and heat it to 500°C, and oxidize it for 10 hours with an oxygen pressure of 3MPa. The oxidized powder was pressed into a green body under an isostatic pressure of 100 MPa, and then sintered in an oxygen atmosphere at 600 °C for 10 h. The sintered green body was hot-pressed at 900°C under a pressure of 300MPa, and then the hot-pressed green body was refired at 850°C in an oxygen atmosphere for 5 hours. The green body after reburning is hot-extruded, the hot-extrus...

Embodiment 2

[0046] In this embodiment, the silver cadmium oxide multi-component reinforced electrical contact material contains components and weight percentages: 6% CdO, 2% ZnO, 0.3% Bi 2 o 3 , 0.1% NiO, 0.5% In 2 o 3 , the balance being Ag

[0047]Weigh 18Kg silver ingot, place it in a medium frequency induction furnace and melt it, then add 1.2Kg Cd, 0.4Kg Zn, 0.3kg Cu, 0.02kg Ni, 0.06kg Bi, 0.1kg In in sequence, after smelting and homogenizing at 1300°C, at 0.3 Under MPa nitrogen pressure, atomize to make powder, then put the atomized powder into a high-pressure container and heat to 850°C, oxidize for 1 hour, and the oxygen pressure is 0.1MPa. The oxidized powder was pressed into a green body under an isostatic pressure of 500 MPa, and then sintered in an oxygen atmosphere at 900 ° C for 2 h. The sintered green body was hot-pressed at 400°C under a pressure of 700MPa, and then the hot-pressed green body was refired at 900°C in an oxygen atmosphere for 2 hours. The green body aft...

Embodiment 3

[0049] In this embodiment, the silver cadmium oxide multi-component reinforced electrical contact material contains components and weight percentages: 7% CdO, 6% SnO 2 , 0.1% CuO, 0.5% NiO, 0.5% Bi 2 o 3 , the balance being Ag

[0050] Weigh 17Kg of silver ingot, place it in a medium frequency induction furnace and melt it, then add 1.4KgCd, 1.2KgZn, 0.02kgCu, 0.1kgNi, 0.1kgBi in sequence, after smelting and homogenizing at 1150°C, atomize and make powder under 5MPa nitrogen pressure, Then put the atomized powder into a high-pressure container and heat it to 650°C, oxidize for 8 hours, and the oxygen pressure is 1MPa. The oxidized powder was pressed into a green body under an isostatic pressure of 250 MPa, and then sintered in an oxygen atmosphere at 750 ° C for 5 h. The sintered green body was hot-pressed at 750°C under a pressure of 500 MPa, and then the hot-pressed green body was refired at 750°C in an oxygen atmosphere for 5 hours. The green body after reburning is hot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com