A kind of tungsten-copper alloy surface nanometerization method

A tungsten-copper alloy and nanotechnology, which is applied in the field of material surface treatment, can solve problems such as partial surface melting and material failure, and achieve the effects of reduced cut-off value, low cost, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

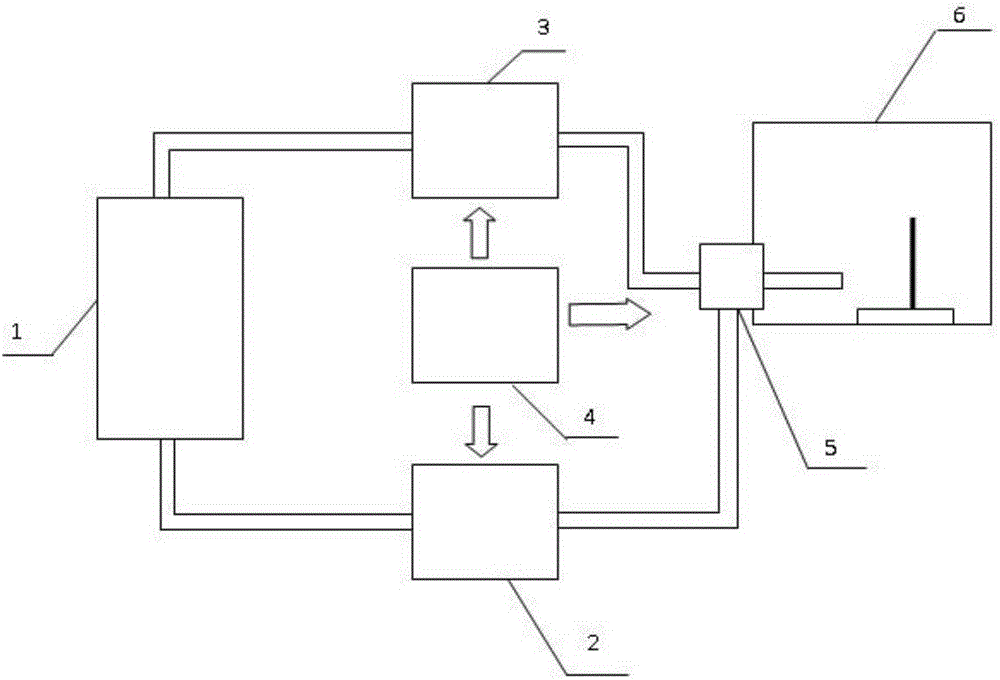

Method used

Image

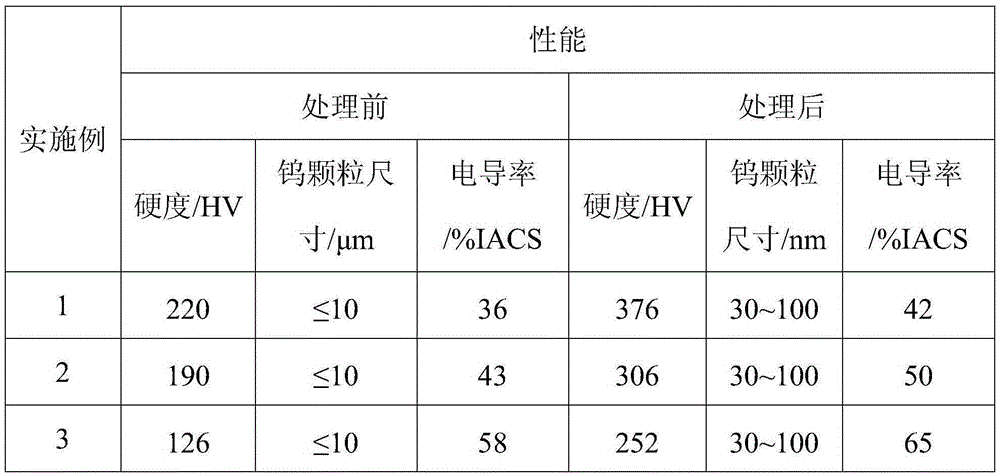

Examples

Embodiment 1

[0028] Step 1, mechanically polishing the surface of the tungsten-copper alloy with a copper content of 20% and cleaning the surface oil with acetone;

[0029] Step 2, place the tungsten-copper alloy pretreated in step 1 in a supersonic particle bombardment device for surface nano-treatment; the process parameters are: gas (air) pressure of 3.5MPa, hard particle size of 0.3mm, hard The particle flow rate is 25g / s, the hard particles are S110 stainless steel, the voltage is 30V, and the processing time is 10min;

[0030] Step 3, place the tungsten-copper alloy that has been treated with surface nanometerization in step 2 in a vacuum furnace, and the vacuum degree is 1×10 -3 Pa, annealing temperature 200°C, and annealing time 30 minutes can be used for stress relief annealing.

[0031] The thickness of the nano-layer on the surface of the tungsten-copper alloy obtained in Example 1 is 0.45 mm.

Embodiment 2

[0033] Step 1, mechanically polishing the surface of a tungsten-copper alloy with a copper content of 30% and cleaning the surface with acetone to remove oil stains;

[0034] Step 2, place the tungsten-copper alloy pretreated in step 1 in a supersonic particle bombardment device for surface nano-treatment; the process parameters are: gas (nitrogen) pressure 2.5MPa, hard particle size 0.3mm, hard The particle flow rate is 20g / s, the hard particles are S110 stainless steel, the voltage is 20V, and the processing time is 60min;

[0035] Step 3, place the tungsten-copper alloy that has been treated with surface nanometerization in step 2 in a vacuum furnace, and the vacuum degree is 1×10 -3 Pa, annealing temperature 200°C, and annealing time 30 minutes can be used for stress relief annealing.

[0036] The thickness of the nano-layer on the surface of the tungsten-copper alloy obtained in Example 2 is 0.8 mm.

Embodiment 3

[0038] Step 1, mechanically polish the surface of the tungsten-copper alloy with a copper content of 50% and clean the surface oil with alcohol;

[0039] Step 2, place the tungsten-copper alloy pretreated in step 1 in a supersonic particle bombardment device for surface nano-treatment; the process parameters are: gas (air) pressure 1.5MPa, hard particle size 0.3mm, hard particle The flow rate is 15g / s, and the hard particles are α-Al 2 o 3 , voltage 20V, processing time 45min;

[0040] Step 3, place the tungsten-copper alloy that has been treated with surface nanometerization in step 2 in a vacuum furnace, and the vacuum degree is 1×10 -3 Pa, annealing temperature 200°C, and annealing time 30 minutes can be used for stress relief annealing.

[0041] The thickness of the nano-layer on the surface of the tungsten-copper alloy obtained in Example 3 is 1.1 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com