A kind of vacuum interrupter contact material surface coating and its treatment method

A vacuum interrupter and contact material technology, applied in the field of sputtering coating, can solve the problems of large Cr phase size, uneven distribution, composition segregation, etc., and achieve high density, easy release of electrons, accurate and reliable composition control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

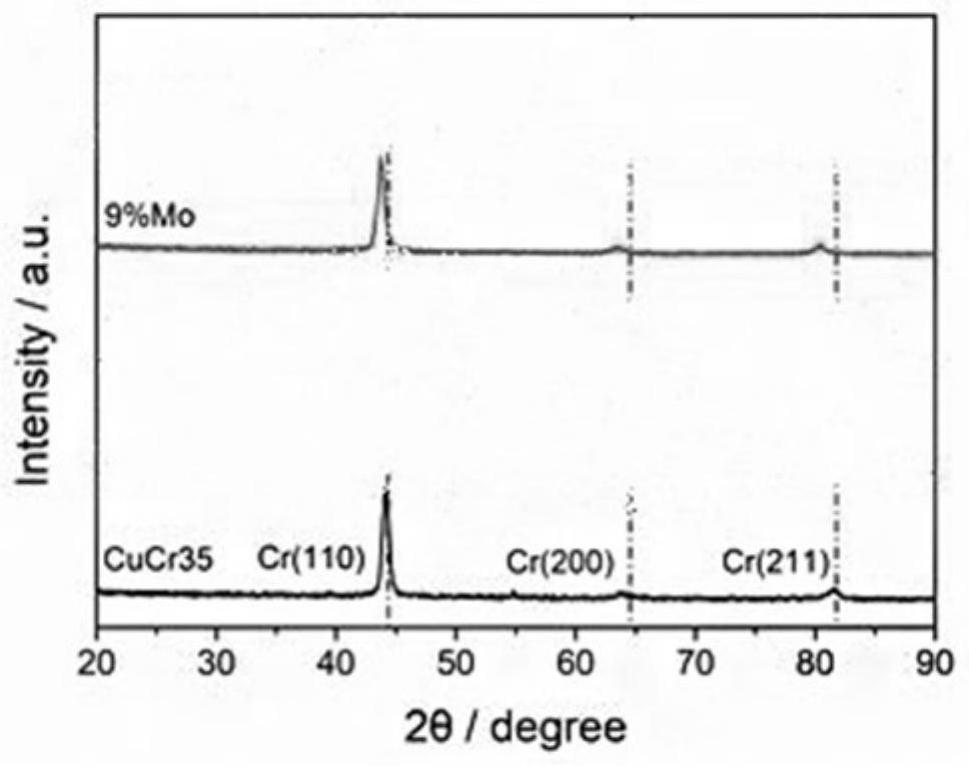

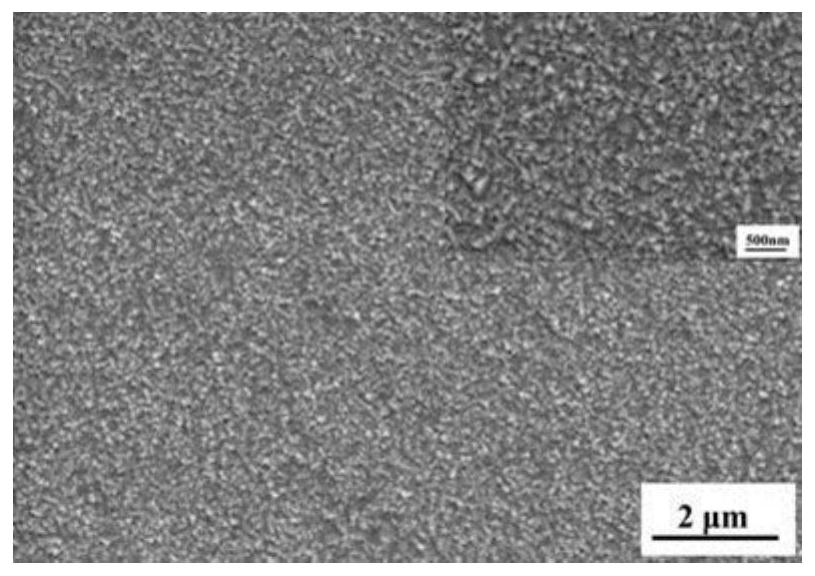

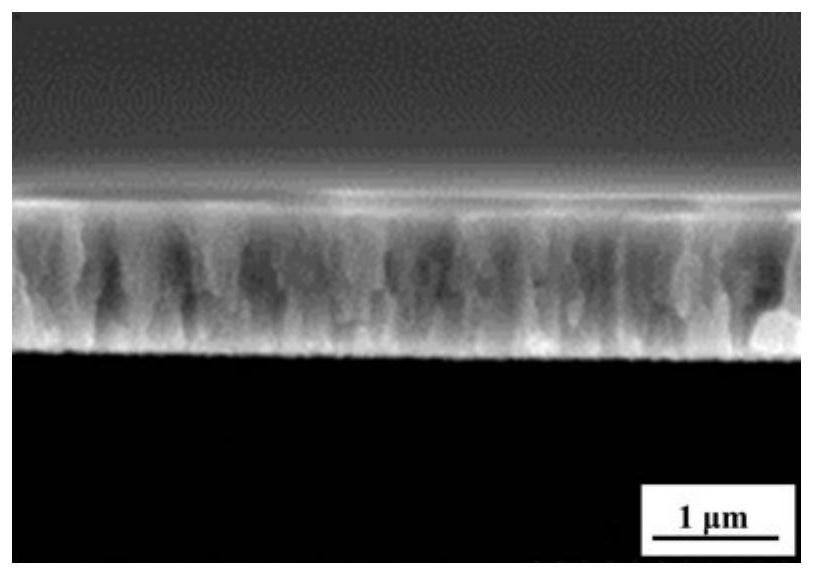

Image

Examples

Embodiment 1

[0034] A method for treating the surface coating of a contact material of a vacuum interrupter provided by the present invention comprises the following steps:

[0035] 1) Clean and dry the CuCr alloy contact material substrate, and clean the equipment.

[0036] 2) Sputtering a CuCrMo alloy film on the surface of the CuCr alloy contact material by using a magnetron sputtering method, and finally obtaining a substrate on which the CuCrMo alloy film grows.

[0037] Specifically, in step 1), the substrate was ultrasonically cleaned with absolute ethanol and deionized water for 10 minutes, and then dried with high-purity nitrogen with a purity of 99.99%. The JPG-450a double-chamber magnetron sputtering The equipment first uses the vacuum equipment to remove the dust in the cavity, and then uses absolute ethanol to scrub the inner wall of the cavity.

[0038] In step 2), the CuCrMo alloy film is sputtered by JPG-450a double-chamber magnetron sputtering equipment. The target is pl...

Embodiment 2

[0043] A method for treating the surface coating of a contact material of a vacuum interrupter provided by the present invention comprises the following steps:

[0044] 1) Clean and dry the CuCr alloy contact material substrate, and clean the equipment.

[0045] 2) Sputtering a CuCrMo alloy film on the surface of the CuCr alloy contact material by using a magnetron sputtering method, and finally obtaining a substrate on which the CuCrMo alloy film grows.

[0046] Specifically, in step 1), the substrate was ultrasonically cleaned with absolute ethanol and deionized water for 15 minutes, and then dried with high-purity nitrogen with a purity of 99.99%. The JPG-450a double-chamber magnetron sputtering The equipment first uses the vacuum equipment to remove the dust in the cavity, and then uses absolute ethanol to scrub the inner wall of the cavity.

[0047] In step 2), the CuCrMo alloy film is sputtered by JPG-450a double-chamber magnetron sputtering equipment. The target is pl...

Embodiment 3

[0051] A method for treating the surface coating of a contact material of a vacuum interrupter provided by the present invention comprises the following steps:

[0052] 1) Clean and dry the CuCr alloy contact material substrate, and clean the equipment.

[0053] 2) Sputtering a CuCrMo alloy film on the surface of the CuCr alloy contact material by using a magnetron sputtering method, and finally obtaining a substrate on which the CuCrMo alloy film grows.

[0054] Specifically, in step 1), the substrate was ultrasonically cleaned with absolute ethanol and deionized water for 12 minutes, and then dried with high-purity nitrogen with a purity of 99.99%. The JPG-450a double-chamber magnetron sputtering The equipment first uses the vacuum equipment to remove the dust in the cavity, and then uses absolute ethanol to scrub the inner wall of the cavity.

[0055] In step 2), the CuCrMo alloy film is sputtered by JPG-450a double-chamber magnetron sputtering equipment. The target is pl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com