Cu-La2O3 contact material and preparation method thereof

A contact material, la2o3-cuso4 technology, applied in the direction of contacts, electrical components, electric switches, etc., can solve the problems of low resistance to deformation, unstable arc, high cost, achieve excellent anti-arc ablation performance, reduce arcing Degree of ablation, effect of good arc stability

Inactive Publication Date: 2011-06-15

XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the contact material widely used at home and abroad is silver-based material, but its cost is high

Although pure copper can be used as a component of the contact material due to its good electrical properties, it has poor oxidation resistance and low deformation resistance, and an oxide film is easily formed on the surface, resulting in an increase in contact resistance and an excessively high conductive temperature rise.

Therefore, poor ablation resistance and arc instability are the main influencing factors.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

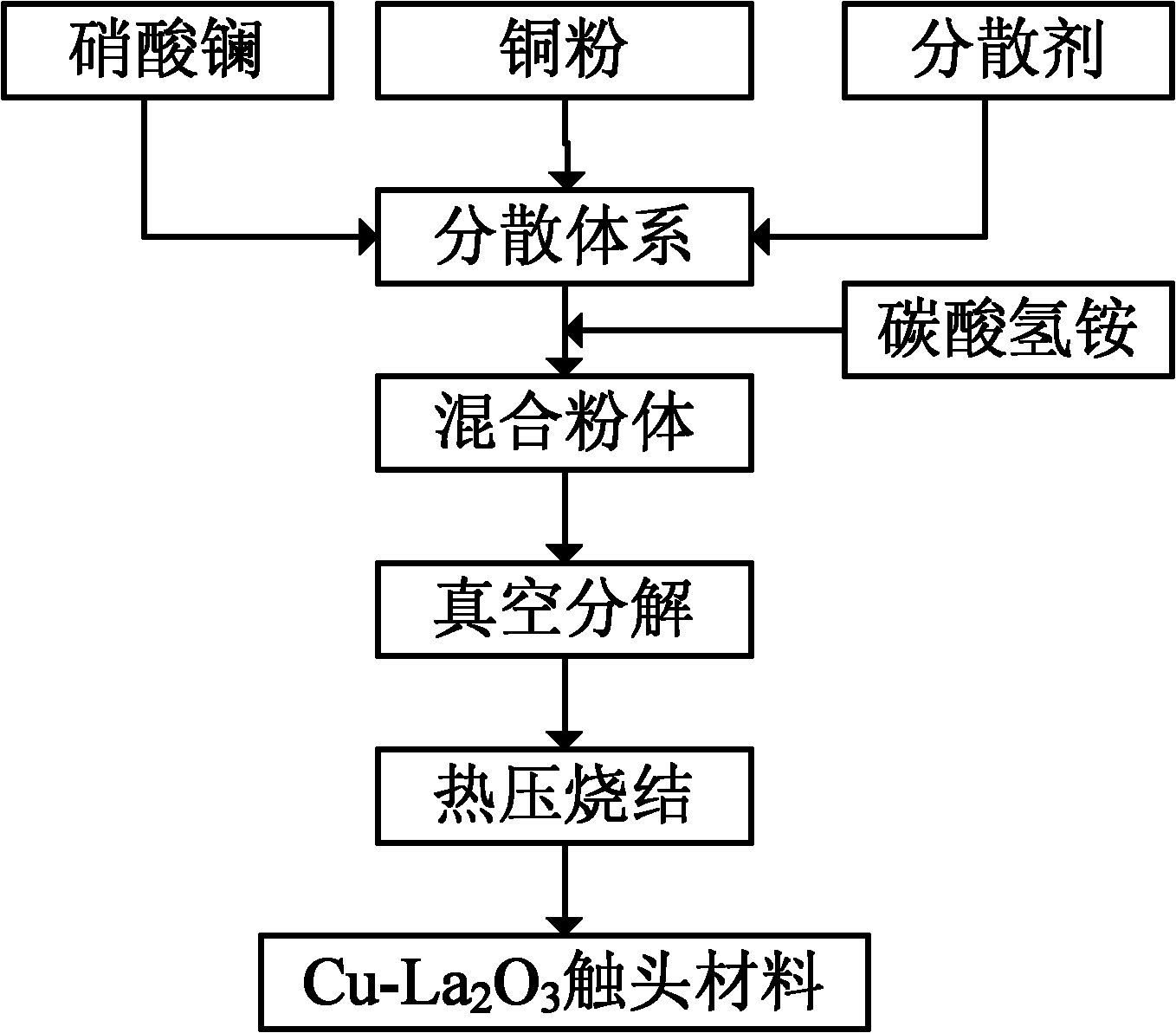

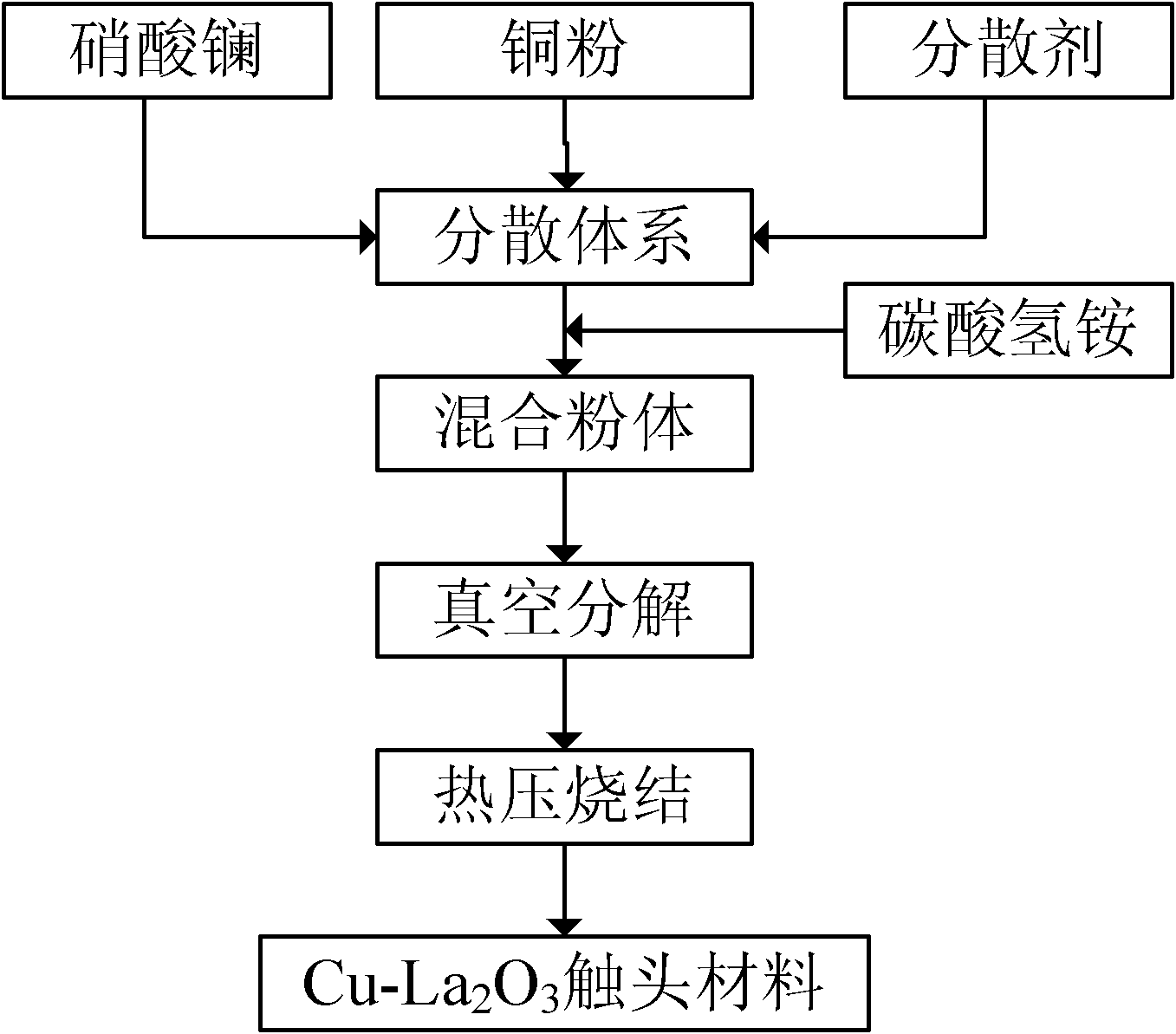

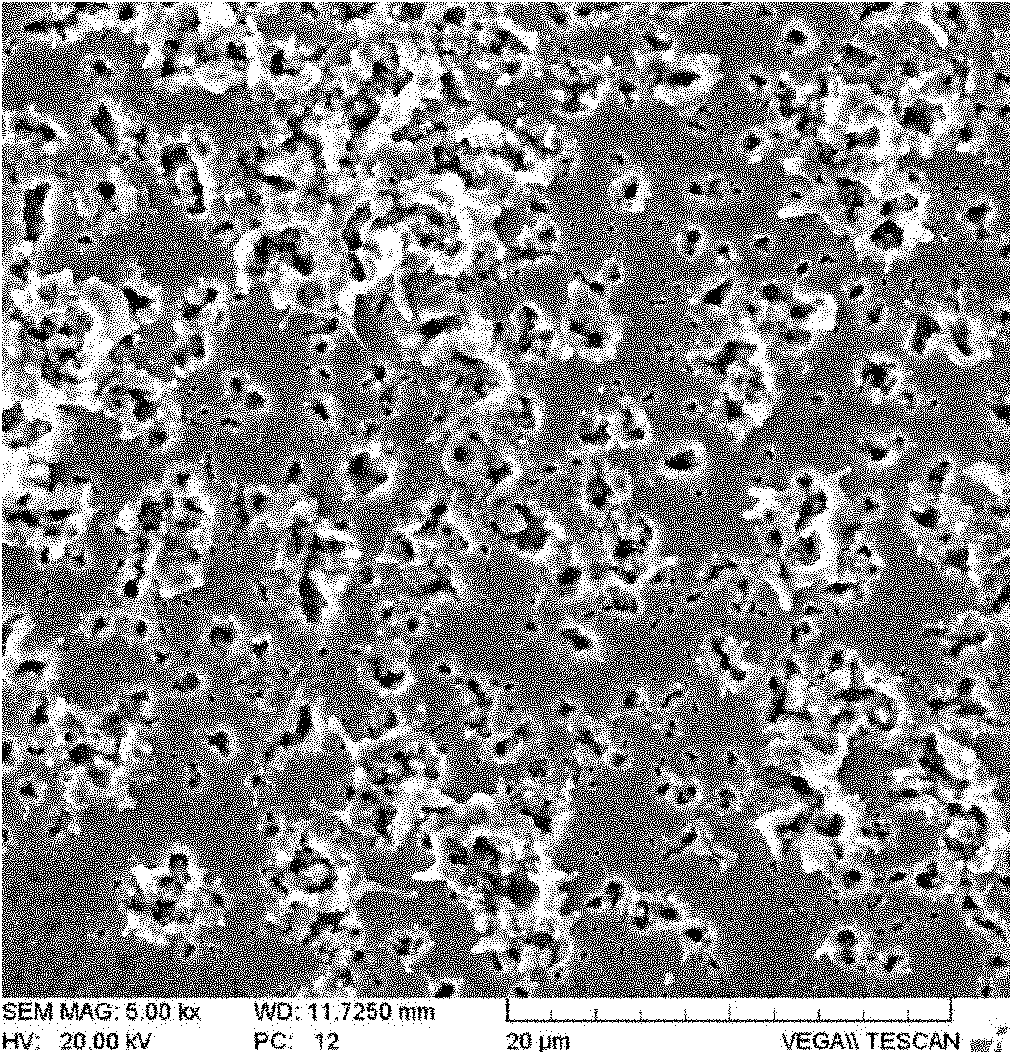

The invention provides a Cu-La2O3 contact material. The contact material is characterized in that La2O3 in the material accounts for 1-5% of the total Cu substrate by weight. The hardness and strength of the material are further improved, the physical property of the material is improved, the material has good arc dispersibility and stability and the comprehensive property of the contact material is improved by adding the rare-earth metal oxide La2O3 to the Cu substrate and uniformly distributing the La2O3 in the substrate. The invention also provides a preparation method of the contact material. The method comprises the following steps: weighing Cu powder, adding the Cu powder to La(NO3)3 solution and then adding a dispersing agent to obtain a dispersion system; adding ammonium bicarbonate to the obtained dispersion system to react at the temperature of 30-40 DEG C for 30-40 minutes, filtering the reactant and roasting the product; placing the obtained mixed powder into a vacuum furnace and keeping the mixed powder under high temperature; and compacting the mixed powder treated in the vacuum furnace and sintering the compact, thus obtaining the Cu-La2O3 contact material.

Description

a Cu-La 2 o 3 Contact material and its preparation method technical field The invention belongs to the technical field of metal composite material preparation, and in particular relates to a Cu-La2O3 contact material and a preparation method thereof. Background technique Contact materials are the key materials of various switches, relays, contactors and other electrical appliances, which play the role of connecting, breaking and transmitting current. At present, the contact material widely used at home and abroad is silver-based material, but its cost is high. Although pure copper can be used as a component of the contact material due to its good electrical properties, it has poor oxidation resistance and low deformation resistance, and an oxide film is easily formed on the surface, resulting in an increase in contact resistance and an excessively high conductive temperature rise. Therefore, poor ablation resistance and arc instability are the main influencing factors. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01H1/025H01H11/04B22F3/16

Inventor 张秋利周军陈向阳宋永辉胡小燕成璇

Owner XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com