Method for manufacturing CuWCr composite material by using WCr alloy powder

A composite material and alloy powder technology, which is applied in the field of manufacturing CuWCr composite materials with WCr alloy powder, can solve the problems of low chromium powder reduction temperature, low density of tungsten-chromium-copper composite materials, insufficient reduction, etc., and achieve material structure and Stable performance, good arc stability, and easy process control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

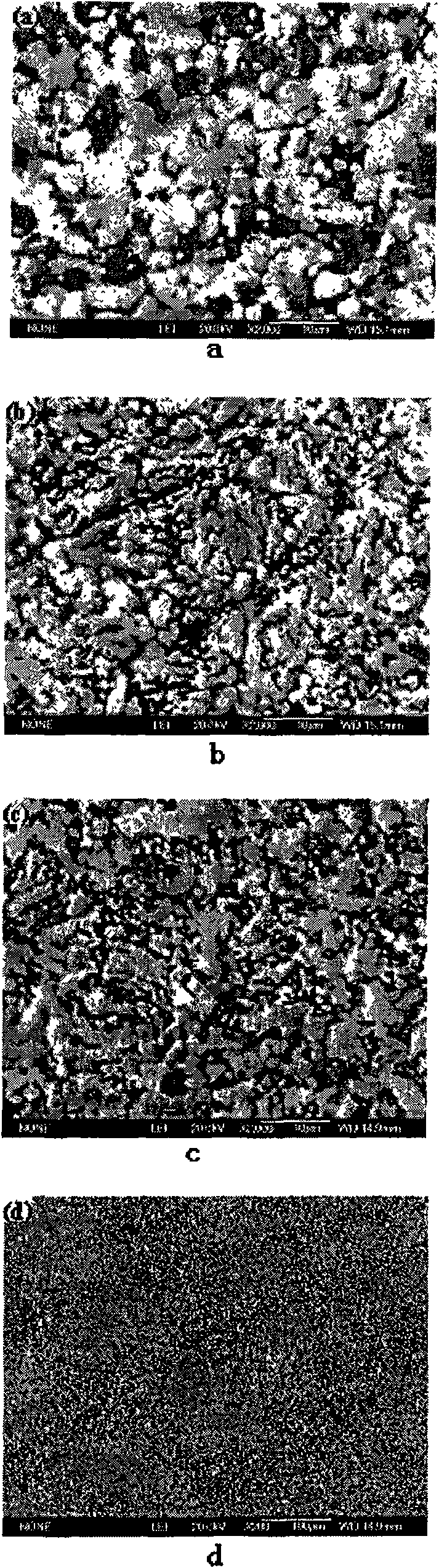

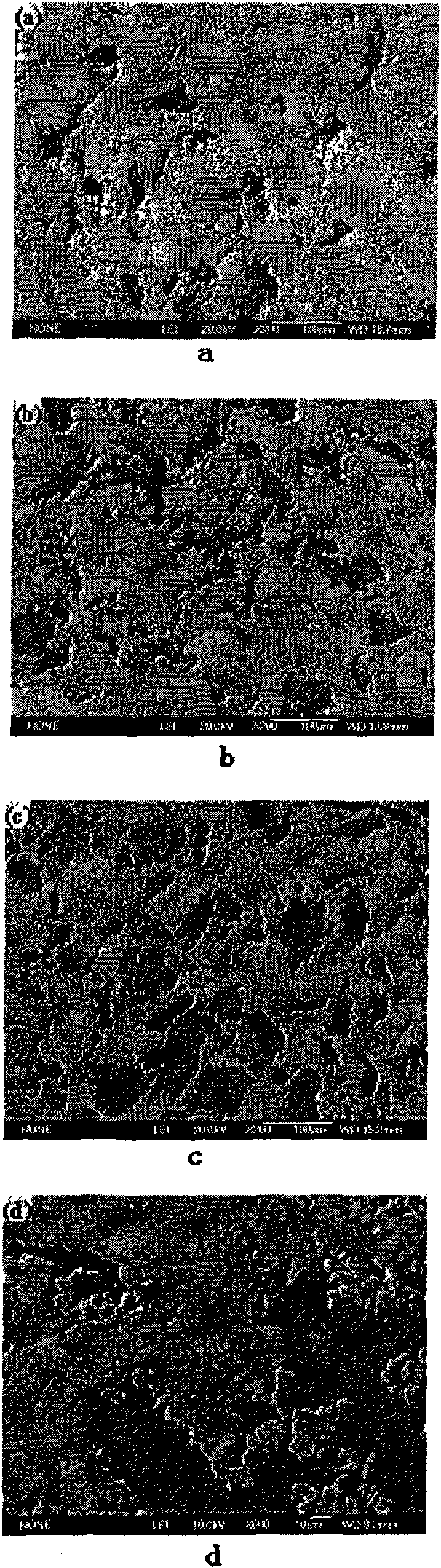

[0020] Put 50% of tungsten powder and 50% of chromium powder into the ball mill, add absolute ethanol to the ball mill tank according to 2% of the total mass of tungsten powder and chromium powder, and add hard alloy according to 50 times the total mass of tungsten powder and chromium powder Grinding balls: Exclude the air in the ball milling tank with nitrogen, seal the ball milling tank, turn on the circulating cooling water in the ball milling tank, and mill for 100 hours; after the ball milling is over, let it stand for cooling, then take out the powder to obtain fully alloyed tungsten Chromium powder.

[0021] The tungsten-chromium alloy powder is molded into a billet, and the porosity of the billet is controlled to 10% according to the composition requirements of copper in the required material. The pressed billet is placed in a hydrogen sintering furnace, and the temperature is raised to 1100 at a rate of 15°C / min. ℃, sintering for 180 minutes to make it sintered into a...

Embodiment 2

[0024] Put 33% of tungsten powder and 67% of chromium powder into the ball mill, add analytical pure acetone in the ball mill tank according to 4% of the total mass of the powder, and add stainless steel grinding balls according to 80 times the total mass of the powder, with different diameters according to 1: 1 configuration; use argon to remove the air in the ball mill tank, and seal the ball mill tank; open the circulating cooling water in the ball mill tank, and mill for 80 hours; after the ball mill is finished, take out the powder after standing for cooling to obtain fully alloyed tungsten Chromium powder.

[0025] The tungsten-chromium alloy powder is subjected to cold isostatic pressing to make a billet, and the porosity of the billet is controlled to 25% according to the composition requirements of copper in the required material, and the pressed billet is vacuum sintered in the furnace to vacuumize to a vacuum degree greater than 10 -2 Pa, heat up to 1500°C at a rate...

Embodiment 3

[0028] Put 25% of tungsten powder and 75% of chromium powder into the ball mill, add absolute ethanol to the ball mill tank according to 5% of the total mass of the powder, and add agate balls according to 100 times the total mass of the powder; Vacuum to 10 -1 Pa, open the cooling water of the ball mill tank, and ball mill for 60 hours; after the ball mill is finished, take out the powder after standing for cooling, and obtain fully alloyed tungsten-chromium alloy powder.

[0029] The tungsten-chromium alloy powder is molded into a billet, and the porosity of the billet is controlled to 40% according to the copper composition requirements in the required material. The pressed billet is placed in a hydrogen sintering furnace, and the temperature is raised to 1450°C at a speed of 20°C / min. , sintered for 100 minutes to form a skeleton;

[0030] Take out the billet after sintering and reduction after cooling, add a sufficient amount of copper block, put it into a vacuum furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com