Corn harvester and grain bin of corn harvester

A corn harvester, granary technology, applied in the direction of harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as poor passing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

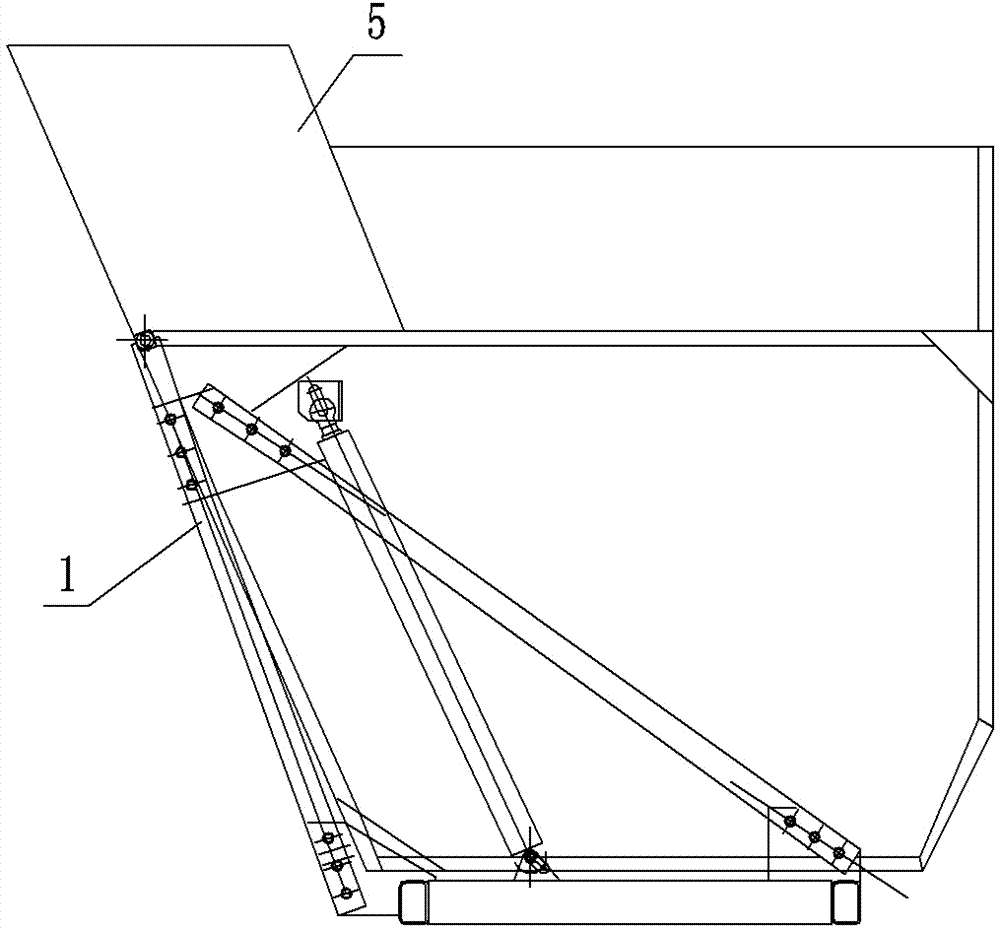

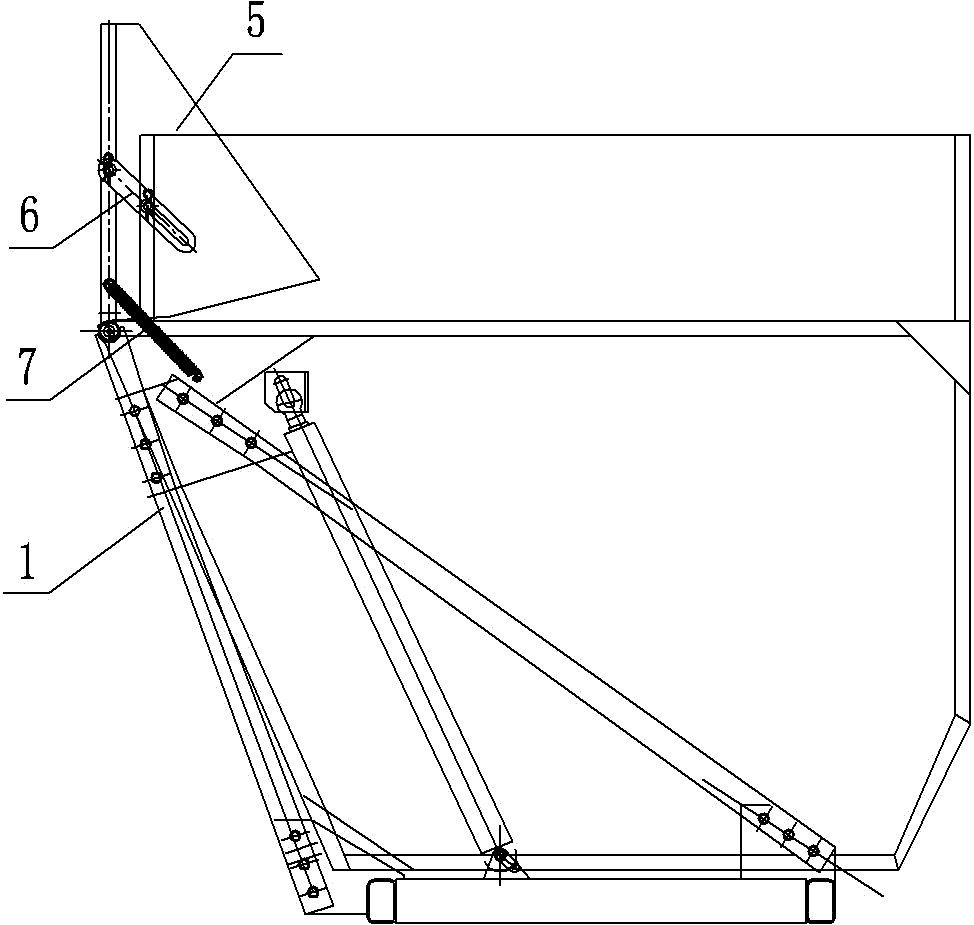

[0015] Embodiment 1 of the corn harvester: the corn harvester of the present embodiment comprises a frame and a header, a peeling machine and a granary arranged on the frame, and the structure of the granary is as follows: figure 2 As shown, the granary comprises a silo body, and the port end of the diversion bin plate 1 of the silo body is provided with a diversion groove 5 for extending the unloading grain diversion surface, and the diversion groove 5 is hinged on the bin body, and the diversion groove 5 is hinged on the bin body. Also be provided with between the runners 5 the elastic piece that makes the diversion groove turn over and reset and the flip limiting mechanism that limits the turning angle of the diversion groove 5, and the diversion groove 5 can move toward the inside and outside of the bin under the action of the flip limiting mechanism. Reciprocating flipping, the flipping limit mechanism has a grain unloading position and a walking position. When the grain ...

Embodiment 2

[0017] Embodiment 2 of the corn harvester: In this embodiment, the difference from Embodiment 1 of the corn harvester is that the flipping limit mechanism of the diversion groove includes an arc-shaped long hole opened on the wall of the diversion groove, and the arc-shaped The center of the long hole is located on the hinge shaft of the diversion groove, and the corresponding warehouse plate of the warehouse body is fixedly provided with a limit guide pin that passes through the arc-shaped long hole and cooperates with the guide movement of the arc-shaped long hole. When the launder is overturned, the limit guide pin cooperates with the two ends of the arc-shaped long hole to limit the overturn angle of the flow-guiding trough, and the two ends of the arc-shaped long hole correspond to the grain unloading position and the walking position respectively. Because the difference between the embodiment 1 of the present embodiment and the corn harvester is very small, the structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com