Clamping device

A technology of clamping device and mandrel, which is applied in the direction of expanding the mandrel, etc., can solve the problems of falling to the ground and inconvenient use, and achieve the effect of reducing the number of times of dropping and picking up and the number of times of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

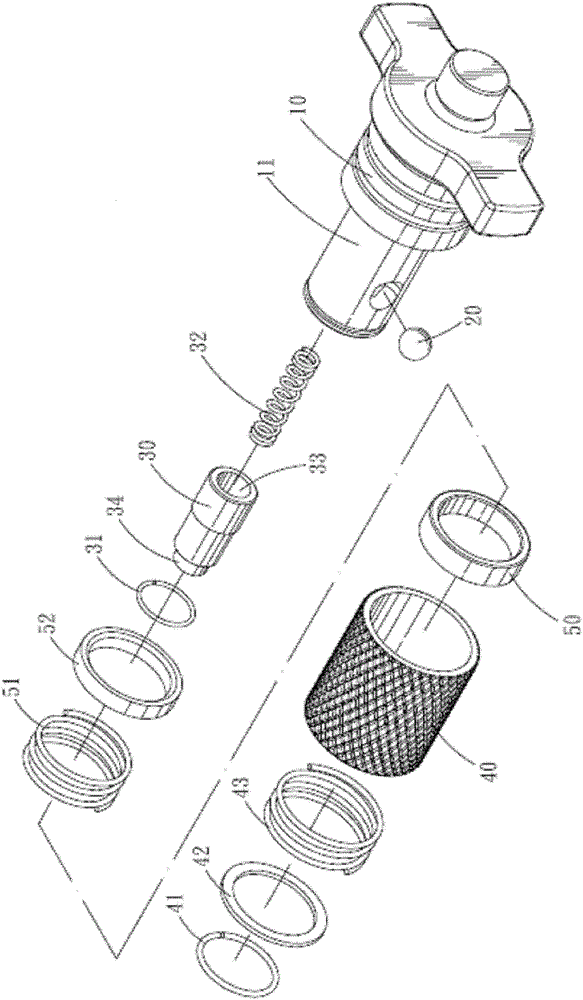

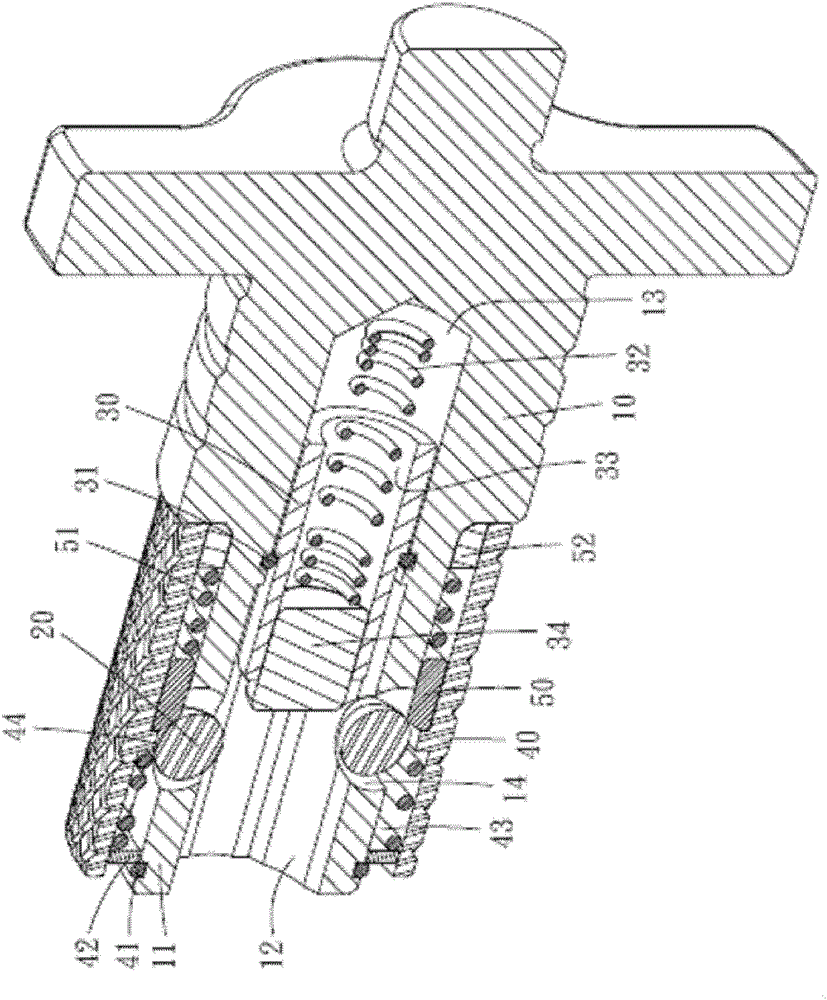

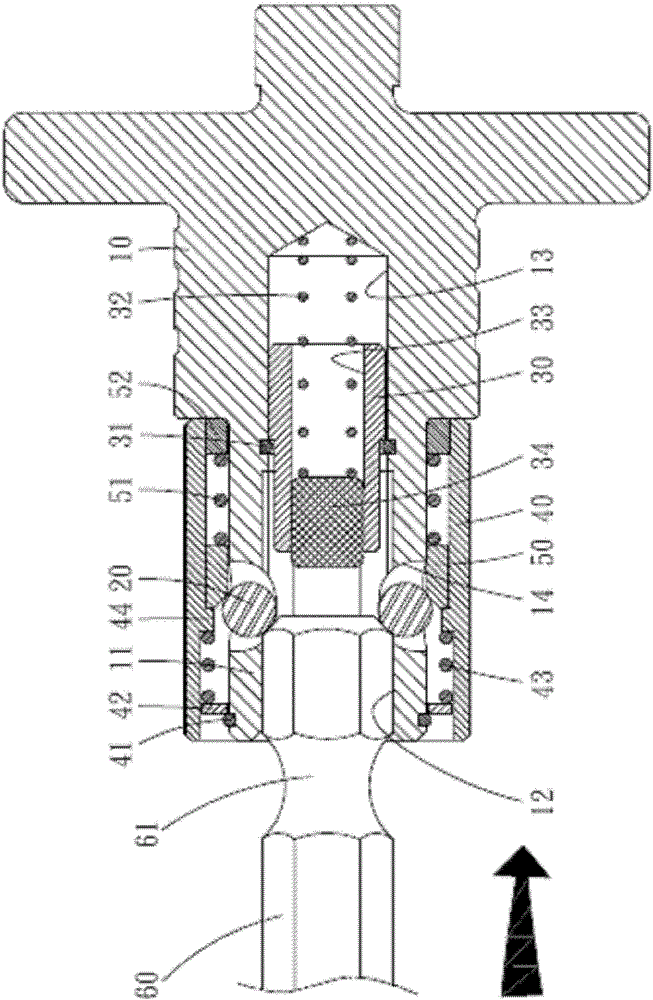

[0030] Embodiment: A clamping device includes a mandrel 10, a sphere 20, a sliding sleeve 30, an outer sleeve 40 and an inner sleeve 50. The mandrel 10 has a specific shape and is suitable for the driving end of a pneumatic (or electric or manual) tool , and protrude from one end of the mandrel 10 in the axial direction to form a cylindrical section 11 with a shrinking diameter. The inner side of the cylindrical section 11 is provided with a hexagonal groove 12, and the bottom of the hexagonal groove is coaxially connected with a circular groove 13. Elastic sliding sleeve 30, an inner retaining spring 31 is embedded in the inner surface of the circular groove 13, and the inner retaining spring 31 stops on the outer end surface of the sliding sleeve 30 so that the sliding sleeve does not bounce off the mandrel 10 but can partially enter the hexagonal groove 12 A radial elongated hole 14 runs through the side wall of the hexagonal groove 12 horizontally, the ball 20 is placed in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com