Current-conducting steel pole tower

A technology of steel rods and diversion grooves, applied in towers, building types, buildings, etc., can solve the problems of large force, poor force displacement performance, etc., to improve the ability to resolve external forces, improve reliability, and enrich the appearance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

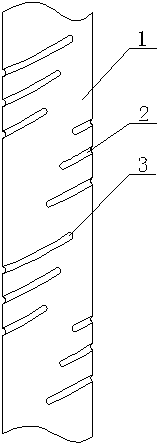

[0012] Such as figure 1 It is a structural schematic diagram of the present invention, a diversion steel pole tower, including a pole body 1, the pole body 1 is a hollow tube, and a flow diversion groove 2 is provided on the outer surface of the pole body 1. The guide grooves 2 are evenly distributed on the cylindrical surface of the rod body 1 . The diversion groove 2 is helical, and is obliquely wound on the rod body 1 . The two ports 3 of each diversion groove 2 are obliquely cut.

[0013] A spiral diversion groove 2 is set on the cylindrical surface of the rod body 1, and the diversion groove 2 is inclined 2 to wrap around the rod body 1. When impacted by strong wind or heavy rain, the force contacts the rod body 1 and walks along the diversion groove 2, After turning around the rod body 1 once, it is evacuated, which greatly reduces the direct impact force on the rod body, thereby improving the reliability of the rod body 1 and ensuring the safety and stability of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com