Special manipulator clamping device for packaging box

A technology of manipulators and packaging boxes, applied in the directions of manipulators, transportation and packaging, chucks, etc., can solve the problems of safety hazards of gripping force and uncontrollable gripping mechanisms, etc., to avoid safety hazards, improve reliability and stability, and improve The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

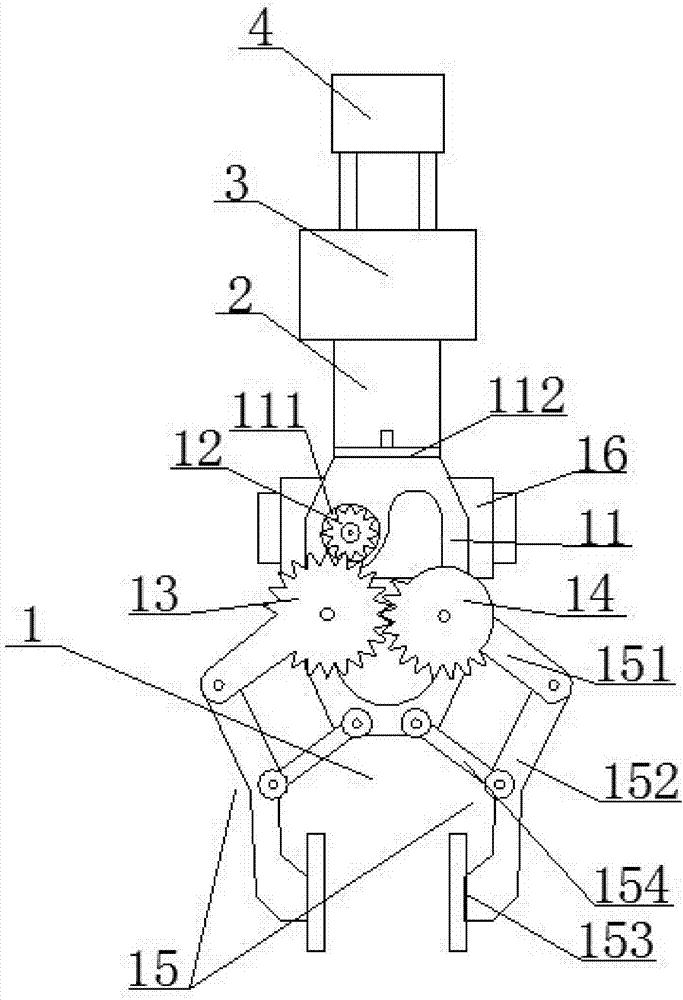

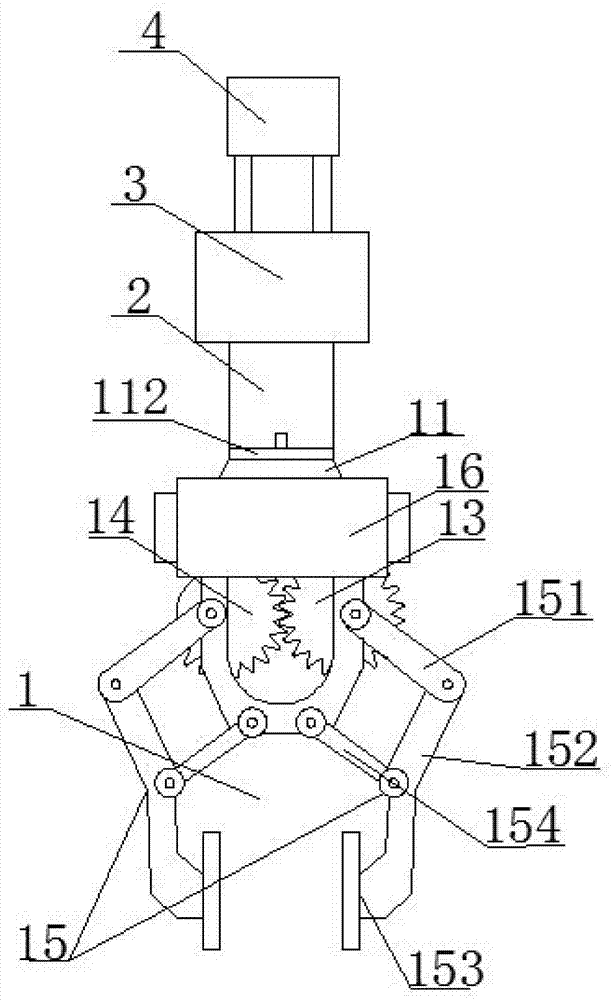

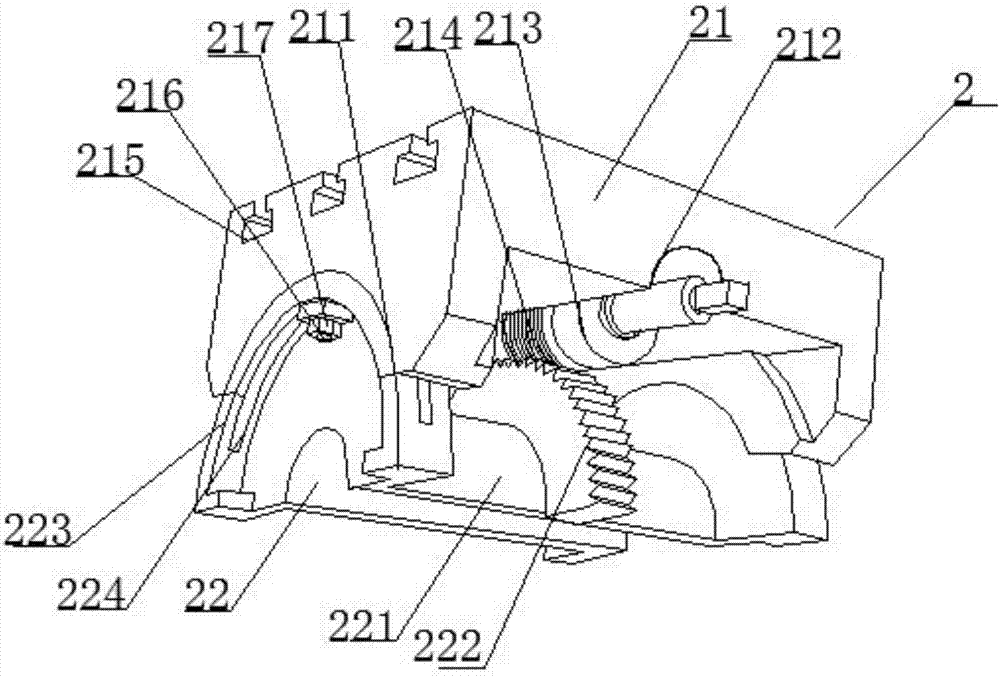

[0027] Such as figure 1 figure 2 As shown, a special manipulator clamping device for packaging boxes includes a clamping mechanism 1, an inclination adjustment mechanism 2, a horizontal adjustment mechanism 3, and a vertical adjustment mechanism 4 connected in sequence. The clamping mechanism includes a frame 11, the A servo motor is provided under the frame 11, and a driving gear 12 is provided on the output shaft of the servo motor. The driving gear 12 is located inside the frame 11, and one side of the driving gear 12 is provided with a first slave that meshes with the driving gear 12 The driving gear 13, the other side of the first driven gear 13 is provided with a second driven gear 14 meshing with the first driven gear 13, and the first driven gear 13 and the second driven gear 14 are symmetrical The same grabbing assembly 15 is provided. The grabbing assembly 15 includes a first link assembly 151. One end of the first link assembly 151 is fixedly connected to the first d...

Embodiment 2

[0029] On the basis of embodiment 1, the first connecting rod assembly 151 includes an upper connecting rod and a lower connecting rod that are stacked, and one end of the upper connecting rod is fixedly connected to the first driven gear 13 or the second driven gear 14 , The first driven gear 13 or the second driven gear 14 and the lower link are hinged to the frame through the same hinge shaft, and the other end of the upper link and the other end of the lower link are hinged to the second link through the same hinge shaft. On the rod 152.

Embodiment 3

[0031] On the basis of Embodiment 1 or 2, the limit rods 154 are provided with two groups, and both ends of the two groups of limit rods 154 are respectively hinged on the frame 11 and the second connecting rod 152 through a hinge shaft. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com