Cooling tower with hinge baffles

A loose-leaf baffle and cooling tower technology, applied in the field of cooling towers, can solve problems such as blockage, affecting cooling effect, and garbage drifting into the air inlet channel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

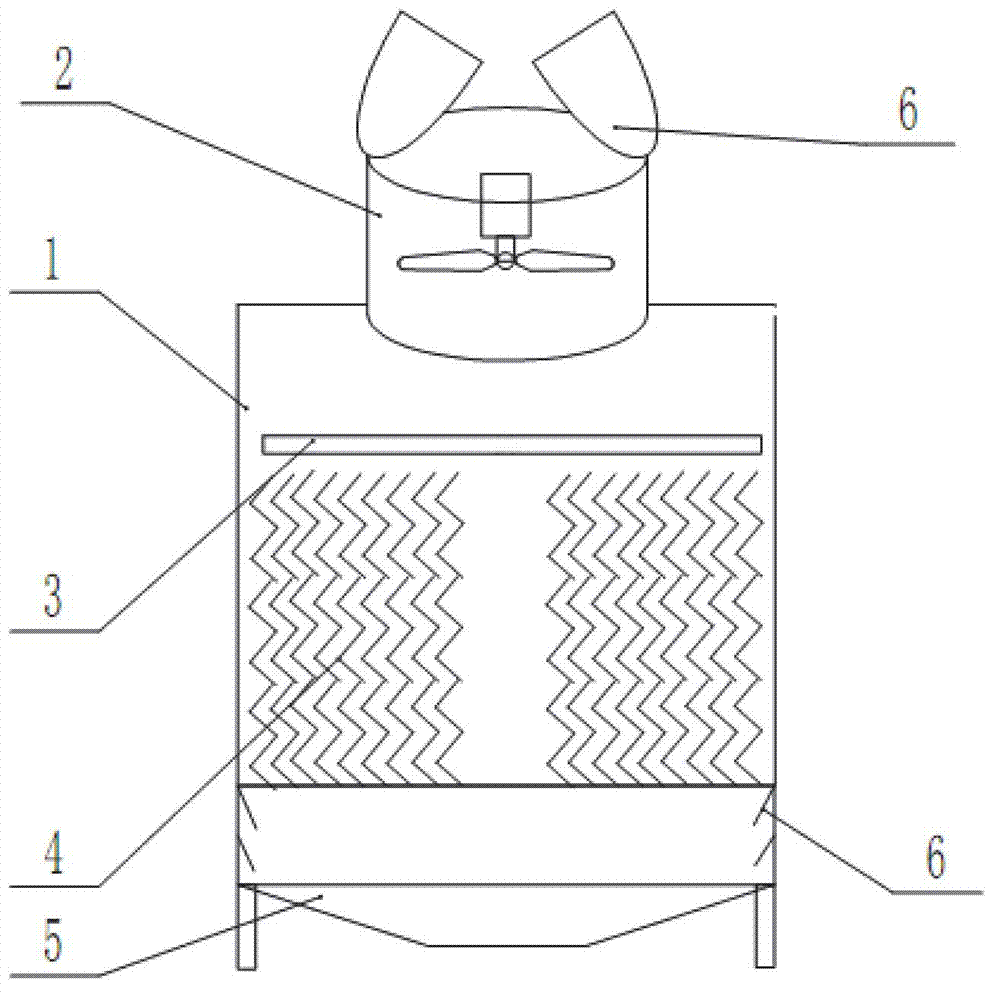

[0009] Such as figure 1 A cooling tower with a loose-leaf baffle is shown, including a tower body 1, a ventilation device 2, a water distribution device 3, a filler 4 and a water collection tank 5, the lower part of the tower body is provided with an air inlet channel, and the outlet end of the ventilation device 2 A loose-leaf baffle 6 that can be flipped up is provided.

[0010] The air inlet channel is also provided with a loose-leaf baffle 6 that can be turned inward.

[0011] When the invention works, the wind blade rotates to generate negative pressure, so that the loose-leaf baffle of the air inlet channel is opened inwardly, and the air enters, and at the same time, the loose-leaf baffle at the outlet of the ventilation device is also opened upward. When the cooling tower is not working, the two loose-leaf baffles are closed to prevent debris from entering the tower body and causing blockage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com