Method of making ziegler-natta type catalysts

一种催化剂、齐格勒的技术,应用在催化剂前体组合物领域,能够解决凝胶等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

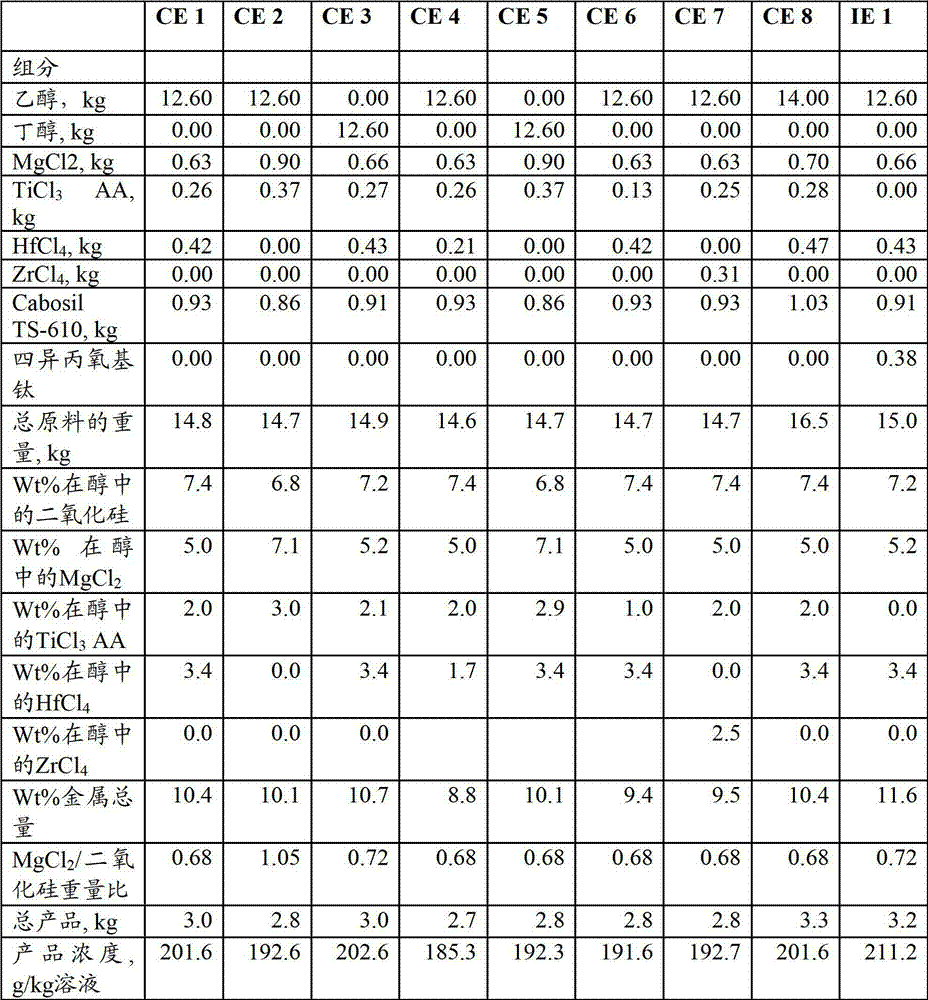

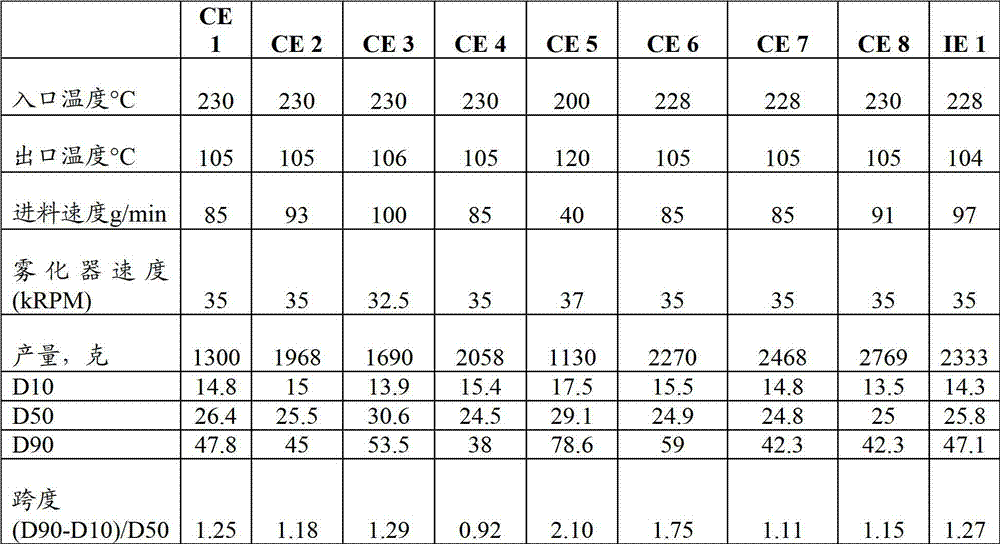

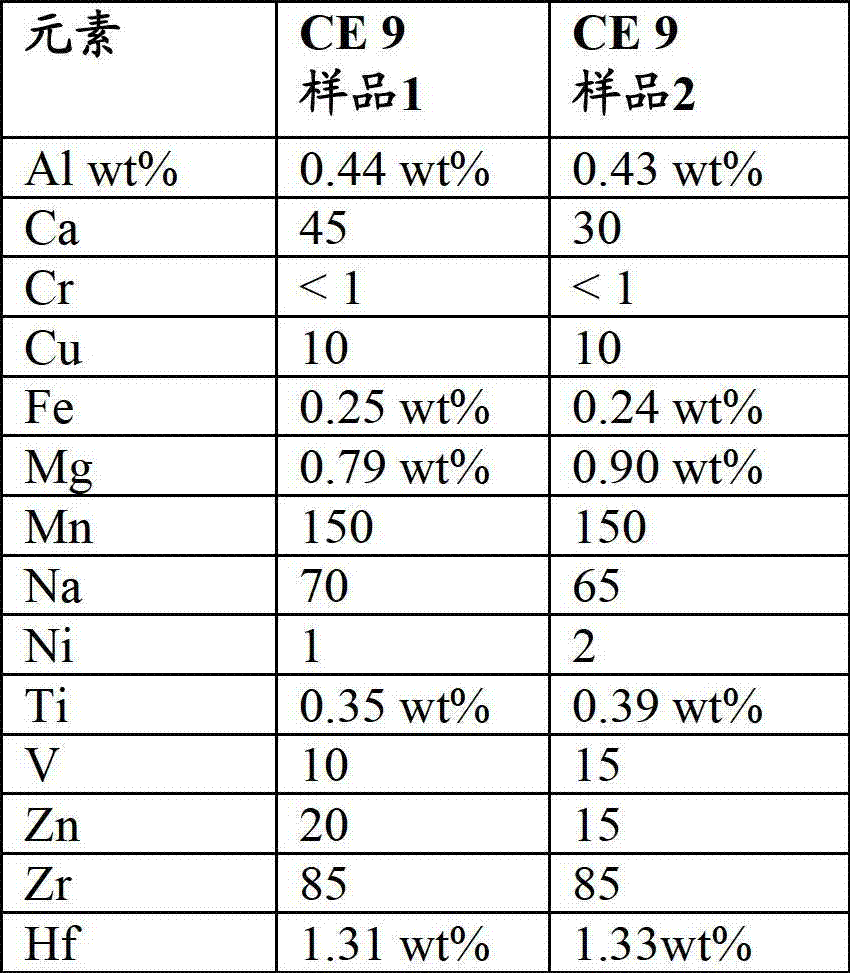

Examples

Embodiment 1

[0109] The hexane and precursor powder were added to the mixing vessel and the temperature was maintained at about 20°C. The ethyl aluminum sesquichloride is added over a period of about 15 to 30 minutes. The temperature was raised to 50°C and stirred for 60 to 70 minutes. After stirring, the slurry was allowed to stand. Temperature reduced to <35°C. Decant the supernatant solvent. Additional solvent (isopentane) was added and the suspension was stirred for 30 minutes. The isopentane solvent was decanted, isopentane was added and the suspension was stirred for an additional 30 minutes. Decant the isopentane again and add mineral oil to the mixing tank, followed by stirring. The jacket temperature of the mixing vessel was increased to 45 to 50°C, purged with nitrogen and the pressure was reduced to remove residual isopentane solvent. When the internal temperature exceeds 35°C, the catalyst slurry is ready for use. Table 4A provides the component analysis of the procatalys...

Embodiment 2

[0126] The raw material was produced according to the procedure given in Example 1 of the present invention. The pH of the raw material solution, before adding Cabosil TS-610, is> 6. That is basically neutral.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com