Electric hub of electric sliding plate and wiring structure

A technology of electric wheel hub and wiring structure, which is applied in the direction of skateboards, ice skating, sports accessories, etc., can solve the problems that affect the overall flexibility and portability of electric skateboards, cannot use the way of outlet, and is not easy to protect the circuit system, etc., to save raw materials, The appearance is simple and beautiful, and the effect of simplifying the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

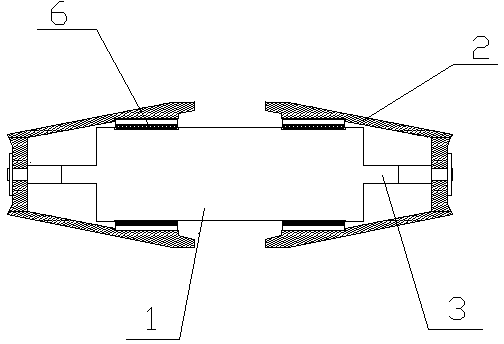

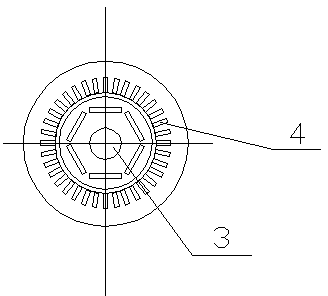

[0055] Embodiment 1: The motor 1 in the electric hub is a motor without a casing, the motor end cover 5 is directly arranged at both ends of the motor stator 4, the bearing 6 is arranged between the motor stator 4 and the hub shell 2, and the two shaft ends of the motor shaft 3 They are respectively fixedly connected with the end cover of the hub shell 2 at this end to form a rotational connection between the motor stator 4 and the hub shell 2; the motor end cover 5 is provided with an outlet hole 7 for the power supply line, and the outer periphery of the motor stator 4 is provided with an inner concave The wiring trough 8 passes through the bonding surface of the bearing 6 and the motor stator 4 along the 9 of the wiring trough.

[0056] More preferably, the wire outlet hole 7 is arranged at the contact section between the motor end cover 5 and the hub shell 2 , the wire outlet hole 7 communicates with the wiring groove 8 , and the motor wire passes through the wire outlet ho...

Embodiment 2

[0060] Embodiment 2: The wire outlet hole 7 is arranged at the installation place of the sub-beam 13 of the bracket of the motor stator 4 , and the motor wire is drawn out through the wire outlet hole 7 and then directly enters the bracket 11 .

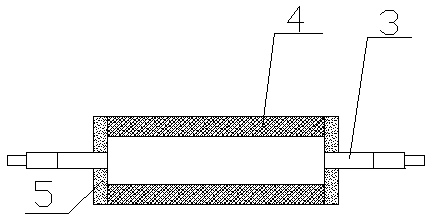

[0061] When the installation space is sufficient, a motor casing 10 is arranged on the periphery of the motor stator 4, motor end covers 5 are arranged at both ends of the motor casing 10, a bearing 6 is arranged between the motor casing 10 and the hub casing 2, and the motor casing 10 and the hub casing 2 Rotational connection; the outlet hole 7 is set on the motor casing 10 .

Embodiment 3

[0062] Embodiment 3: The outlet hole 7 is set between the motor end cover 5 and the bearing 6, and the inner concave wiring groove 8 is opened on the outer periphery of the motor casing 10, and the wiring groove groove along the 9 passes through the attachment of the bearing 6 and the motor casing 10. meet face.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com