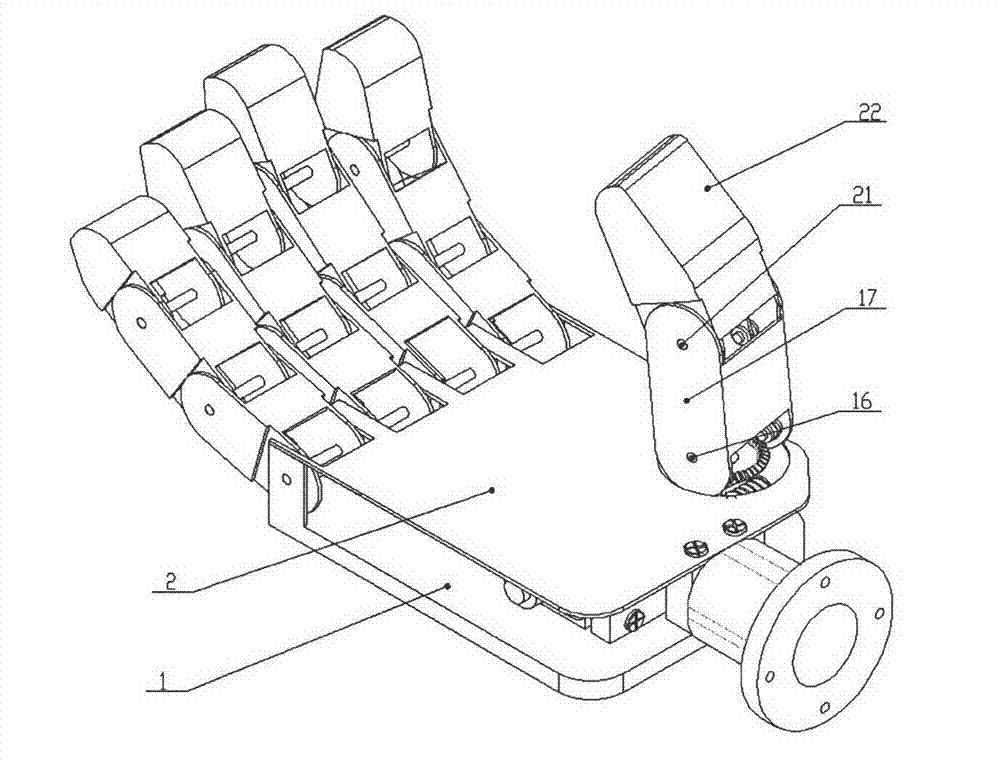

Thumb mechanism of artificial hand

A thumb and prosthetic hand technology is applied in the field of artificial prosthetic thumb mechanism to achieve the effects of small size, reliable movement and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

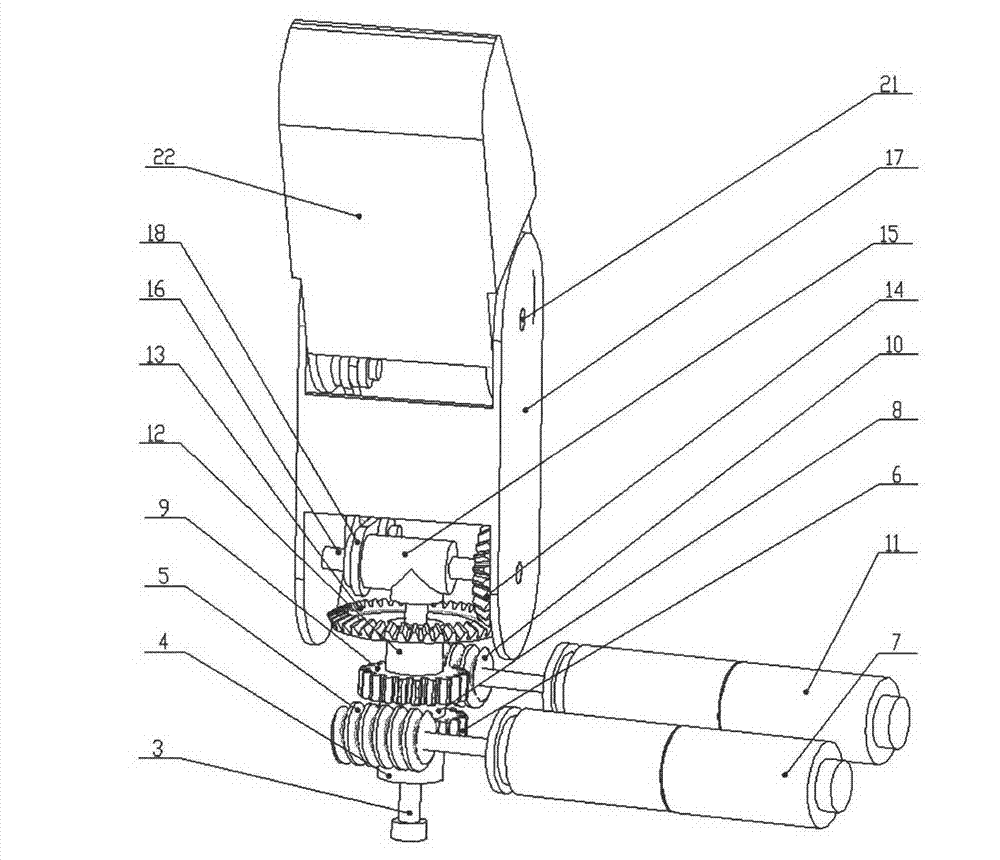

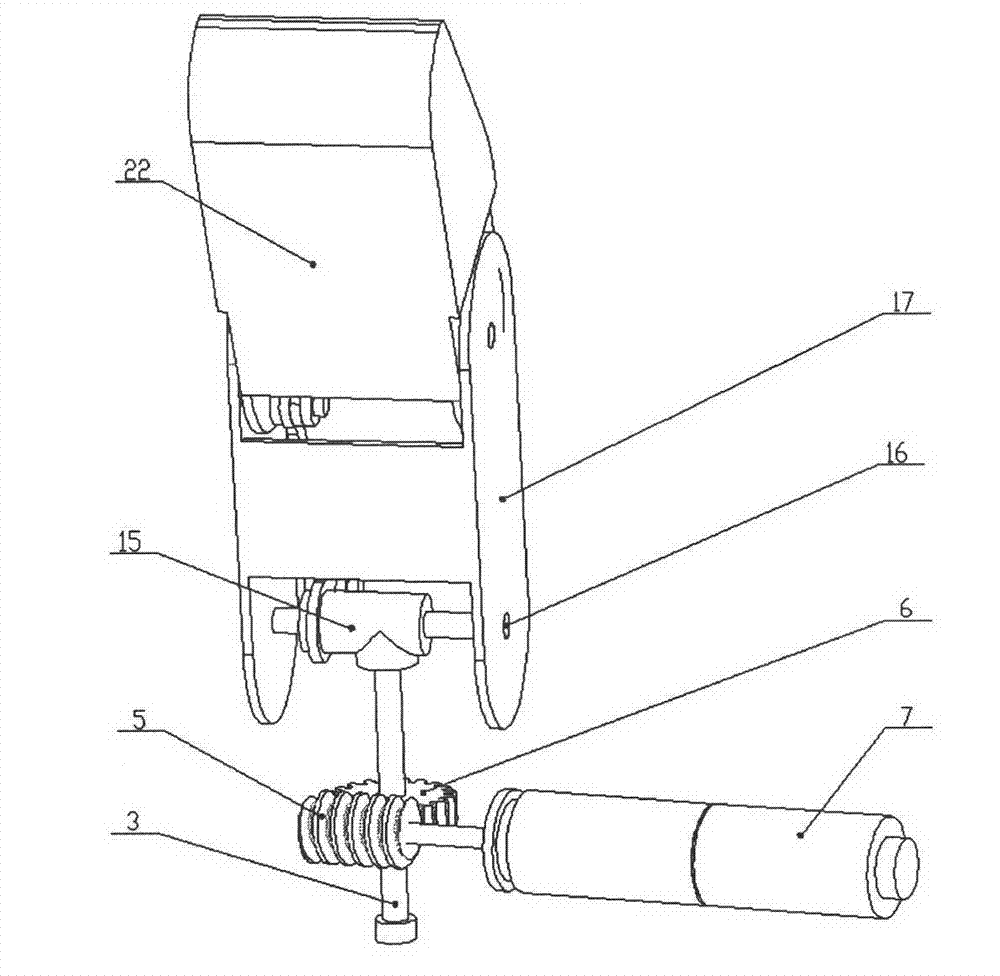

[0017] Implementation of the thumb rotation function:

[0018] Such as image 3 As shown, the motor 7 rotates, the main shaft of the motor 7 is fixedly connected with the worm screw 5, the worm screw 5 rotates, the worm screw 5 and the worm wheel 6 implement worm gear transmission, the worm wheel 6 rotates, the worm wheel 6 is fixedly connected with the thumb rotation shaft 3, and the thumb rotation shaft 3 Rotate, the thumb rotation shaft 3 is fixedly connected with the cross connector 15, the cross connector 15 rotates, the cross connector 15 is horizontally hinged with the first knuckle rotation shaft 16, the first knuckle rotation shaft 16 rotates, and the first knuckle rotates The shaft 16 is fixedly connected to the first knuckle 17, and the first knuckle rotates, thereby realizing the rotation of the thumb.

[0019] In realizing the motion control that the thumb only rotates and does not bend, it should be ensured that the rotating speed of the motor 7 is the same as t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com