Toothpick filling machine

A filling machine and toothpick technology, which is applied in packaging, transportation and packaging, and the type of packaged items, can solve problems such as increased labor costs, error in the number of toothpicks, and difficulty in ensuring toothpick hygiene, so as to achieve mechanized operation and ensure cleanliness , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below in conjunction with accompanying drawing, the invention will be further described:

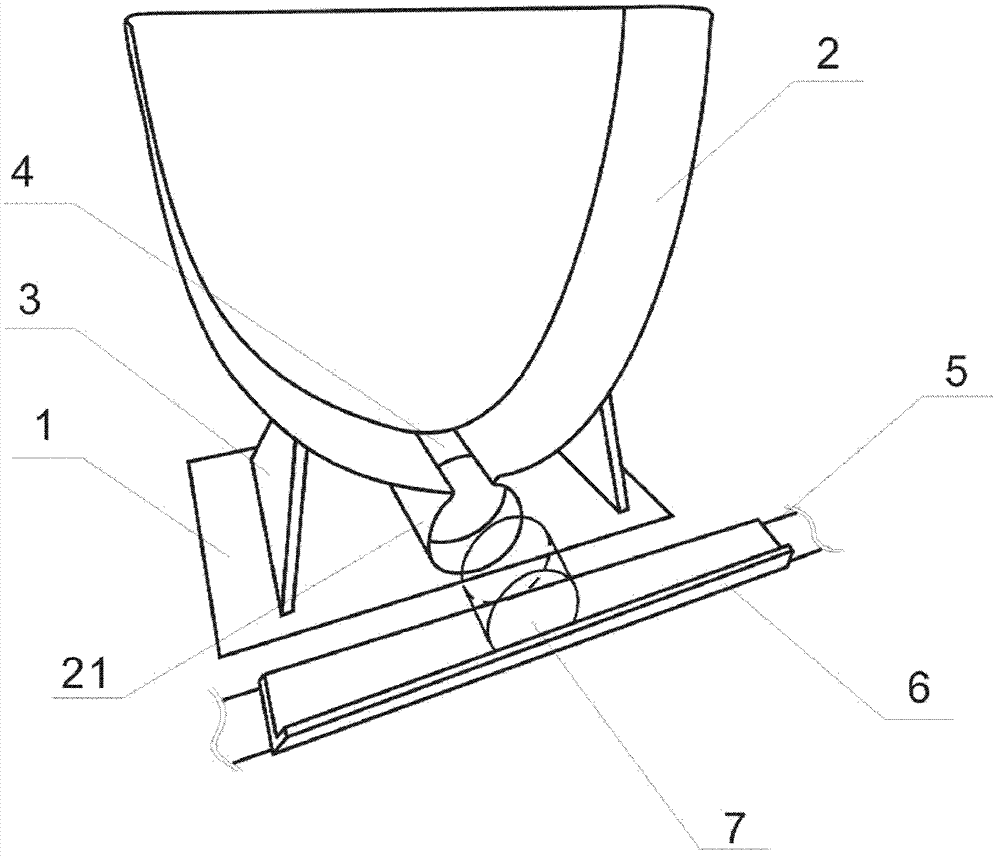

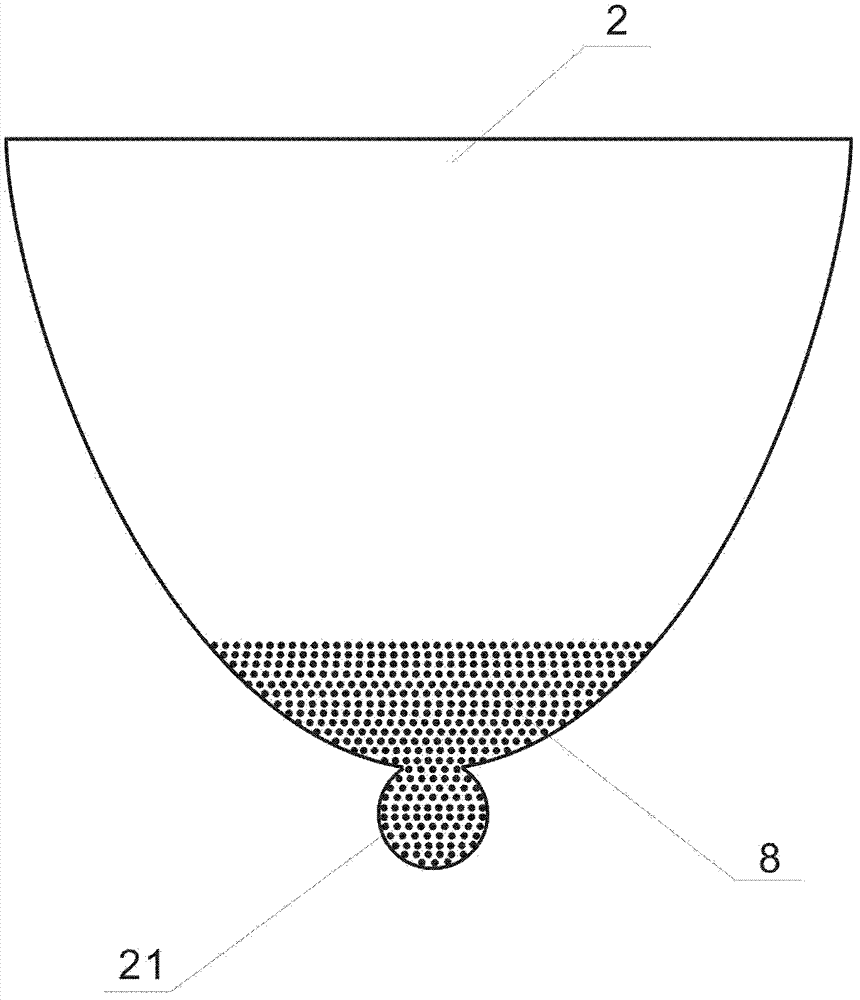

[0015] like figure 1 , 2 Shown is an embodiment of the toothpick filling machine of the present invention, which includes a frame 1, a conical hopper 2 and a toothpick box holder 5. The conical hopper 2 is welded and fixed on the frame 1 through the support plate 3 arranged on the outside of the hopper. The discharge part of the hopper is in the shape of a horizontal cylinder. There is a piston 4 inside the discharge cylinder 21. The rear end of the piston 4 is connected to a cam drive mechanism. The cam mechanism is driven by a motor. The piston 4 can perform linear reciprocating motion in the discharge cylinder 21 . The inner hole of the discharging cylinder 21 is circular, and the aperture is compatible with the toothpick box 7 calibers. Toothpick case 7 is placed on toothpick case holder 6, and toothpick case holder 6 sides butts against toothpick case 7 bottoms, and descr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap