Polymer type boron-containing flame retardant and preparation method thereof

A technology of flame retardants and polymers, applied in the field of flame retardants and their preparation, can solve the problems of poor washing resistance and achieve the effects of not easy migration, excellent durability, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

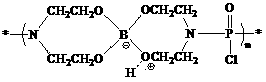

Method used

Image

Examples

Embodiment 1

[0025] Add 12.366g (0.2mol) of boric acid, 46.26g (0.44mol) of diethanolamine and 70ml of toluene into a three-necked flask equipped with magnetic stirring, thermometer, and oil-water separator, heat, stir and reflux until the separated water reaches 10.6ml to end the reaction. The toluene was distilled off under reduced pressure to obtain a light yellow transparent viscous liquid. Excess diethanolamine was removed by washing with tetrahydrofuran. Vacuum drying at 50°C gave 37.20 g of a colorless transparent viscous liquid with a yield of 85.30%. Its purity is 98.83% by titration with 0.1mol / L hydrochloric acid solution.

[0026] In a 250ml three-neck flask equipped with magnetic stirring, dropping funnel and thermometer, add 32.7g of diethanolamine borate and 150ml of dichloromethane, add 22.9g of phosphorus oxychloride in the dropping funnel, dilute with 20ml of dichloromethane After the diethanolamine borate is completely dissolved, the phosphorus oxychloride is added dro...

Embodiment 2

[0029] Wherein the synthetic method of intermediate diethanolamine borate is with example 1.

[0030] In the 250ml four-necked bottle equipped with magnetic stirring, dropping funnel and thermometer, add diethanolamine borate 21.8g and 100ml acetonitrile, add 15.3g phosphorus oxychloride in the dropping funnel, it is diluted with 10ml acetonitrile, After the diethanolamine borate is completely dissolved, start to add phosphorus oxychloride dropwise. At this time, the temperature rises and a white solid is formed. After the addition, continue to react for 1 hour; then raise the temperature to 100°C and keep it at 100°C for 5 hours. , cooled to room temperature, filtered, washed with 100ml of dichloromethane, filtered, and dried at 50°C to obtain a white powder product.

[0031] Add 3.3g of diethanolamine borate and phosphorous oxychloride cocondensate, 1.2g of melamine, 35ml of DMF, and 5ml of pyridine into a three-neck flask with a temperature agent and a reflux condenser, hea...

Embodiment 3

[0033] Wherein the synthetic method of intermediate diethanolamine borate is with example 1.

[0034] In the 500ml four-necked bottle equipped with magnetic stirring, dropping funnel and thermometer, add diethanolamine borate 43.6g and 200ml acetonitrile, add 30.6g phosphorus oxychloride in the dropping funnel, it is diluted with 20ml acetonitrile, After the diethanolamine borate is completely dissolved, start to add phosphorus oxychloride dropwise. At this time, the temperature rises, and a white solid is formed. After the addition, continue to react for 2 hours; then slowly raise the temperature to 85°C, and keep 85°C for reaction After 10 hours, filter, wash with 100ml of dichloromethane, filter, and dry at 50°C to obtain a white powder product.

[0035] Add 10.0g of diethanolamine borate and phosphorus oxychloride cocondensation polymer, 2.82g of phenol, 80ml of DMF, and 4.250g of triethylamine into a three-necked flask with a temperature agent and a reflux condenser, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com