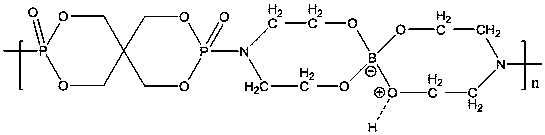

A kind of polymerized flame retardant integrated with boron, nitrogen and phosphorus and preparation method thereof

A phosphorus flame retardant and polymerized technology, applied in the field of boron-nitrogen-phosphorus-integrated polymerized flame retardant and its preparation, can solve the problems of poor polymer compatibility, great influence on flame retardant efficiency, influence on material mechanical properties, etc. , to achieve the effect of not easy migration, good smoke suppression and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0024] Add 12.366g of boric acid, 46.26g of diethanolamine and 70ml of toluene into a three-necked flask equipped with magnetic stirring, thermometer, oil-water separator and reflux condenser, stir and heat to reflux until the separated water reaches 10.6ml to end the reaction. The toluene was distilled off under reduced pressure to obtain a light yellow transparent viscous liquid. Excess diethanolamine was removed by washing with tetrahydrofuran. Vacuum drying at 80°C gave a colorless transparent viscous liquid with a yield of 86.8%. Its purity is 98.98% by titration with 0.1mol / L hydrochloric acid solution.

[0025] with magnetic stirring, thermometer, N 2 Add 18.15g of pentaerythritol, 33ml of phosphorus oxychloride, 0.1g of 2-methylaminopyridine and 100ml of chlorobenzene into the 250ml three-necked flask of the catheter and reflux condenser (connected with HCl tail gas absorption device), and pass N 2 protection, react at 60°C for 2h, then raise the temperature to 100°...

Embodiment 2

[0028] Wherein the synthetic method of intermediate boric acid diethanolamine ester and dipentaerythritol dichlorophosphate is with example 1.

[0029] In a 250ml three-neck flask equipped with a magnetic stirrer, a thermometer, and a vacuum decompression device, add 23.98g of diethanolamine borate, 32.67g of dipentaerythritol dichlorophosphate and 80ml of acetonitrile, react at 80°C for 1 hour, and then evaporate the solvent under reduced pressure , using the vacuum melting method to react at 160°C for 1 hour. After the reaction, keep the vacuum state to room temperature, and finally grind to obtain a bright yellow powdery solid, wash with 80ml tetrahydrofuran, filter, and dry at 80°C to obtain the flame retardant.

Embodiment 3

[0031] Wherein the synthetic method of intermediate boric acid diethanolamine ester and dipentaerythritol dichlorophosphate is with example 1.

[0032] In a 250ml three-neck flask equipped with a magnetic stirrer, a thermometer, and a vacuum decompression device, add 41.42g of boric acid diethanolamine ester, 50.49g of dipentaerythritol dichlorophosphate and 120ml of acetonitrile, react at 80°C for 2 hours, and then evaporate the solvent under reduced pressure , using the vacuum melting method to react at 180°C for 1 hour. After the reaction, keep the vacuum state to room temperature, and finally grind to obtain a bright yellow powdery solid, wash with 100ml tetrahydrofuran, filter, and dry at 80°C to obtain the flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com