Connecting structure of steel joint and aluminium alloy drill pipe body

A technology of aluminum alloy pipe and connection structure, which is applied in the direction of drill pipe, drill pipe, casing, etc., can solve the problems of poor sealing performance, low connection strength between aluminum alloy pipe body and steel joint, improve the bearing direction, and help Effective in sealing and matching process safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

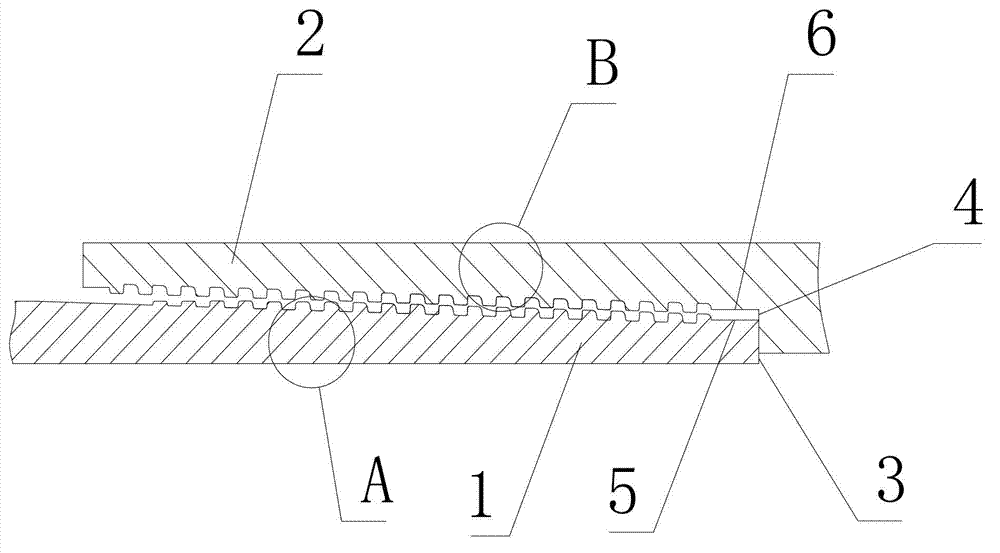

[0020] Such as figure 1 As shown, the connection structure between the steel joint and the aluminum alloy drill pipe body includes:

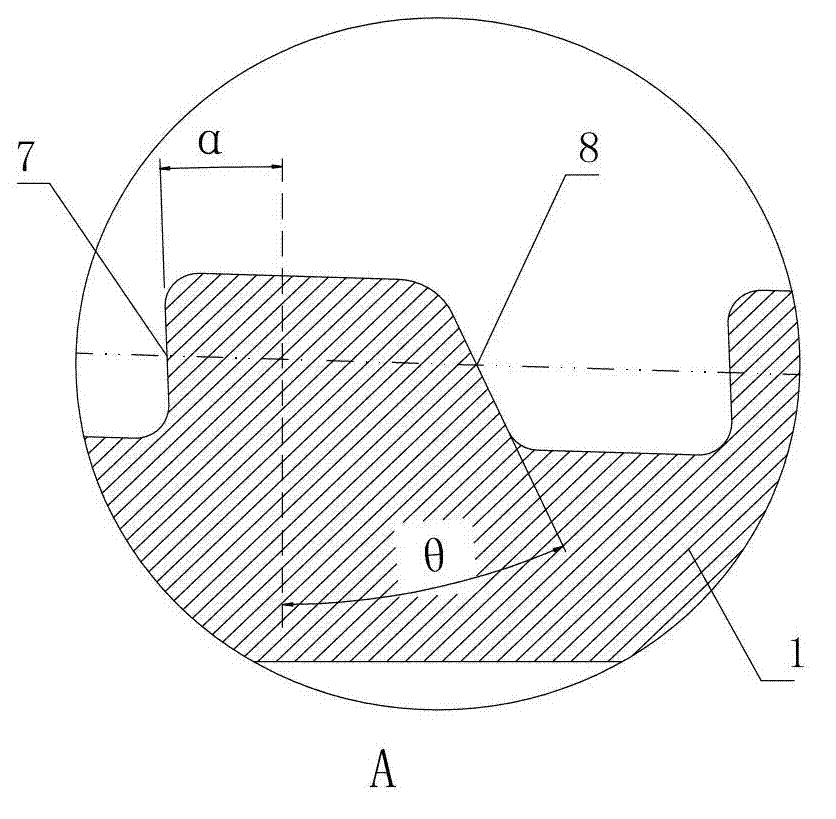

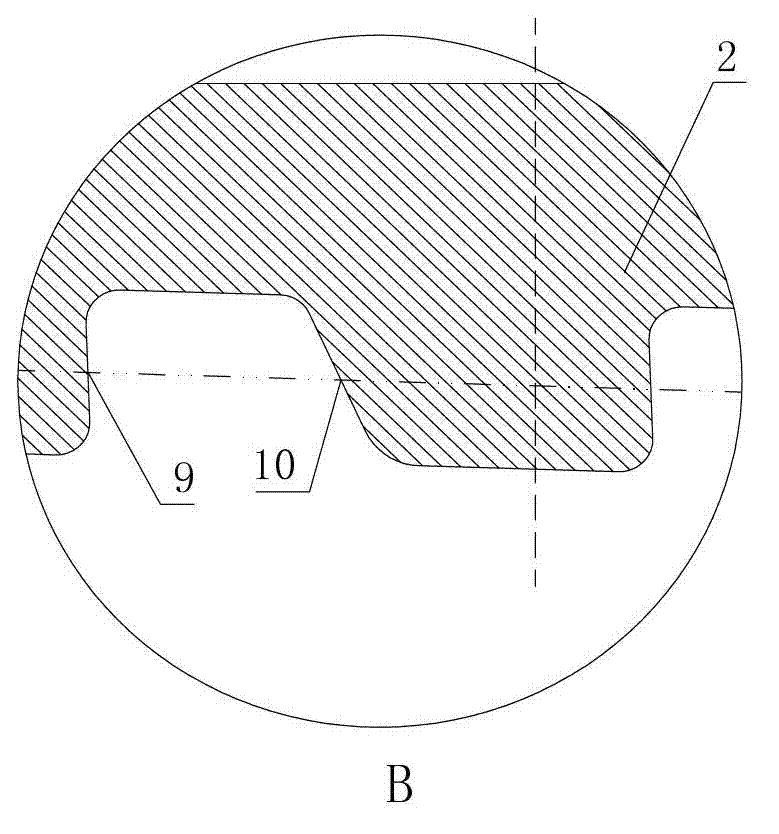

[0021] The outer thread 1 of the aluminum alloy pipe is arranged on the body of the aluminum alloy drill pipe; the sealing end face 5 of the aluminum alloy pipe is arranged on the body of the aluminum alloy drill pipe and connected to the outer thread 1 of the aluminum alloy pipe End (right end); aluminum alloy pipe end face shoulder 3, arranged on the aluminum alloy drill pipe body and connected to the end (right end) of the aluminum alloy pipe body sealing end face 5, the aluminum alloy pipe The body sealing end face 5 is connected between the external thread 1 of the aluminum alloy pipe and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap