Method for quantitative analysis of wire rod sorbite content by using imager standard sample method

A standard sample, quantitative analysis technology, applied in the analysis of materials, material analysis by optical means, instruments, etc., can solve the problems of long analysis time, large analysis error, cumbersome operation, etc., to achieve high analysis accuracy, high quantitative analysis, Good traceability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

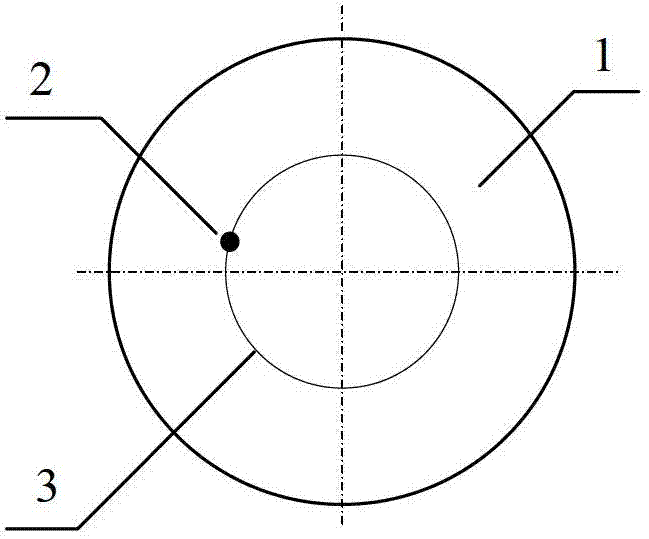

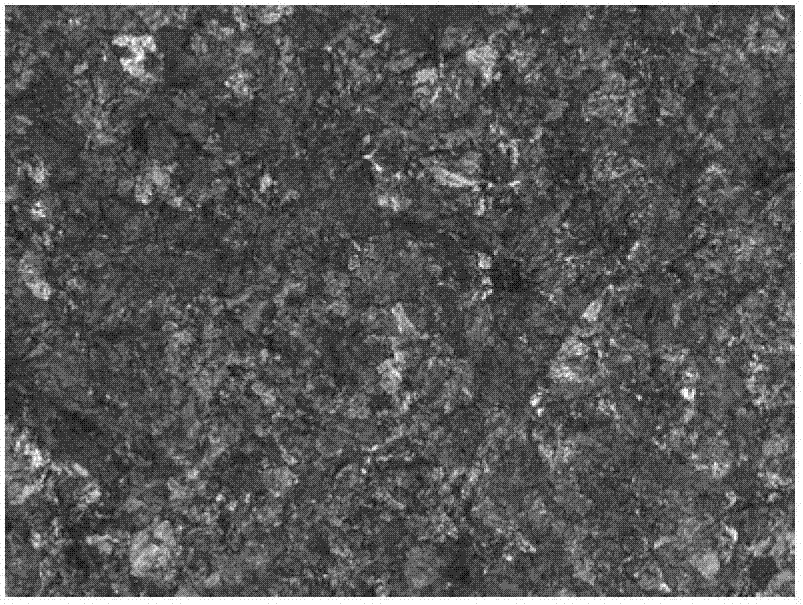

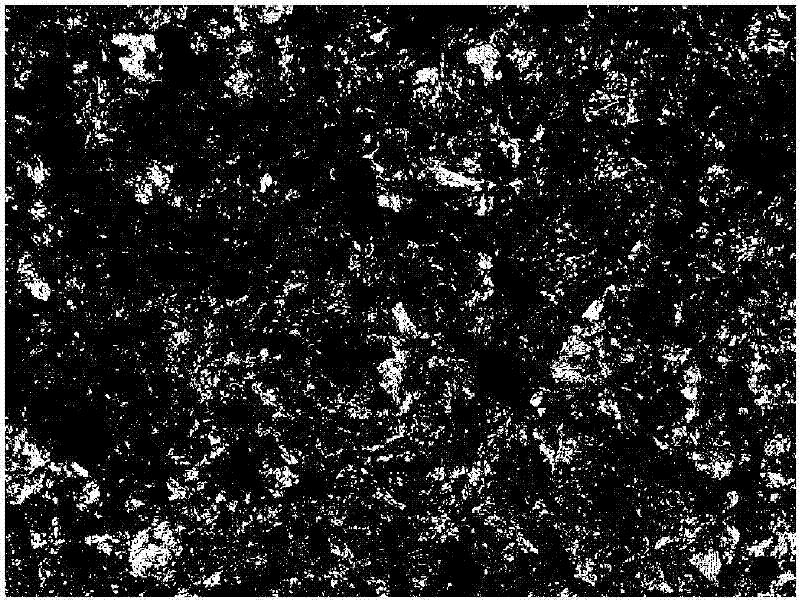

[0024] The wire rod used in the experiment is SWRH82B high carbon steel sorbite wire rod, such as figure 1 As shown, sample wire rod 1, analysis point 012, R 0.5 Analysis ring 3.

[0025] See Table 1 for ingredients

[0026] Table 1 Chemical composition % of experimental wire rod

[0027]

[0028] Take a roll of wire rod from the experimental furnace number and inlay it into a metallographic sample, sample number: 12-1, and the quantitative analysis steps of its sorbite content are as follows:

[0029] 1) The steel type of the experimental wire rod is 82B sorbite wire rod, so the "SWRH82B sorbite wire rod sorbite percentage content standard sample 1#" standard sample 1, standard sample 1 sorbite percentage content standard Value Ss = 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com