Wire terminal structure and manufacturing method thereof

A wire terminal and manufacturing method technology, applied in the field of wire terminal structure, can solve the problems of unfavorable long-term use, unsatisfactory plating conductivity, low hardness, etc., and achieve the effect of not being easily deformed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

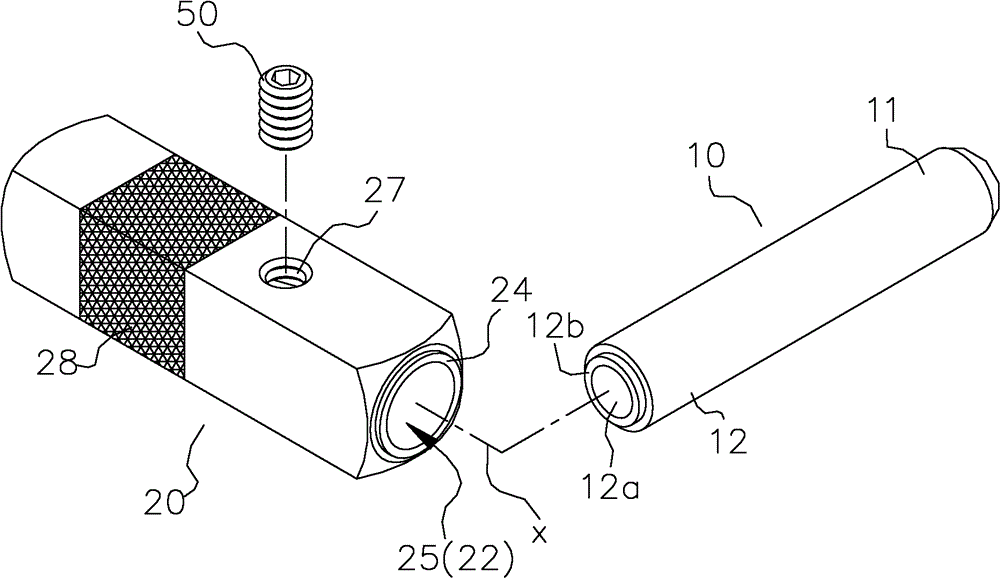

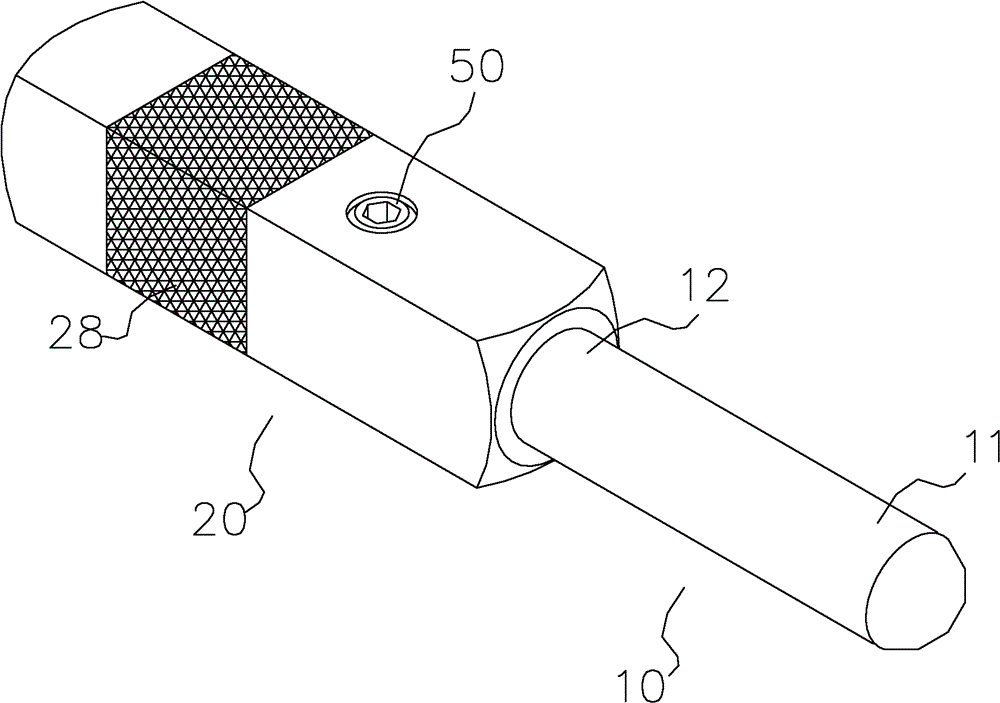

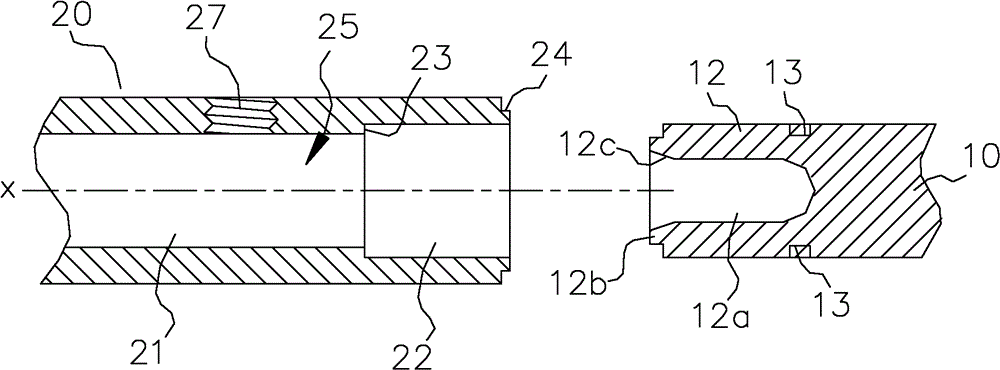

[0067] like figure 1 , figure 2 As shown, the wire terminal structure of the present invention includes: a conductor 10 and a seat 20. The conductor 10 selects a material with better conductivity (for example, red copper or similar materials) to form a column or rod structure type of. The conductor 10 has a first end 11 and a second end 12 . The first end 11 is used to insert the signal end or the power end of the electronic product; the second end 12 includes a cavity 12a for pivoting a (ground) wire to form a ground wire mechanism.

[0068] like image 3 , Figure 4 As shown, corresponding to the conductor 10 , the seat 20 defines a cavity 25 in the direction of the axis x; the cavity 25 includes a first area 21 and a second area 22 . The second area 22 is used to combine the second end 12 of the conductor 10 ; the inner diameter of the second area 22 of the chamber is larger than that of the first area 21 ; a neck 23 is formed between the second area 22 and the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com