Water jacket structure for cooling of motor stator

A motor stator and water jacket technology, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of insufficient heat transfer capacity, heat transfer dead zone, large flow resistance and other problems in the design of flat water channels, so as to reduce resistance , Improve heat transfer capacity, avoid the effect of stagnant flow area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

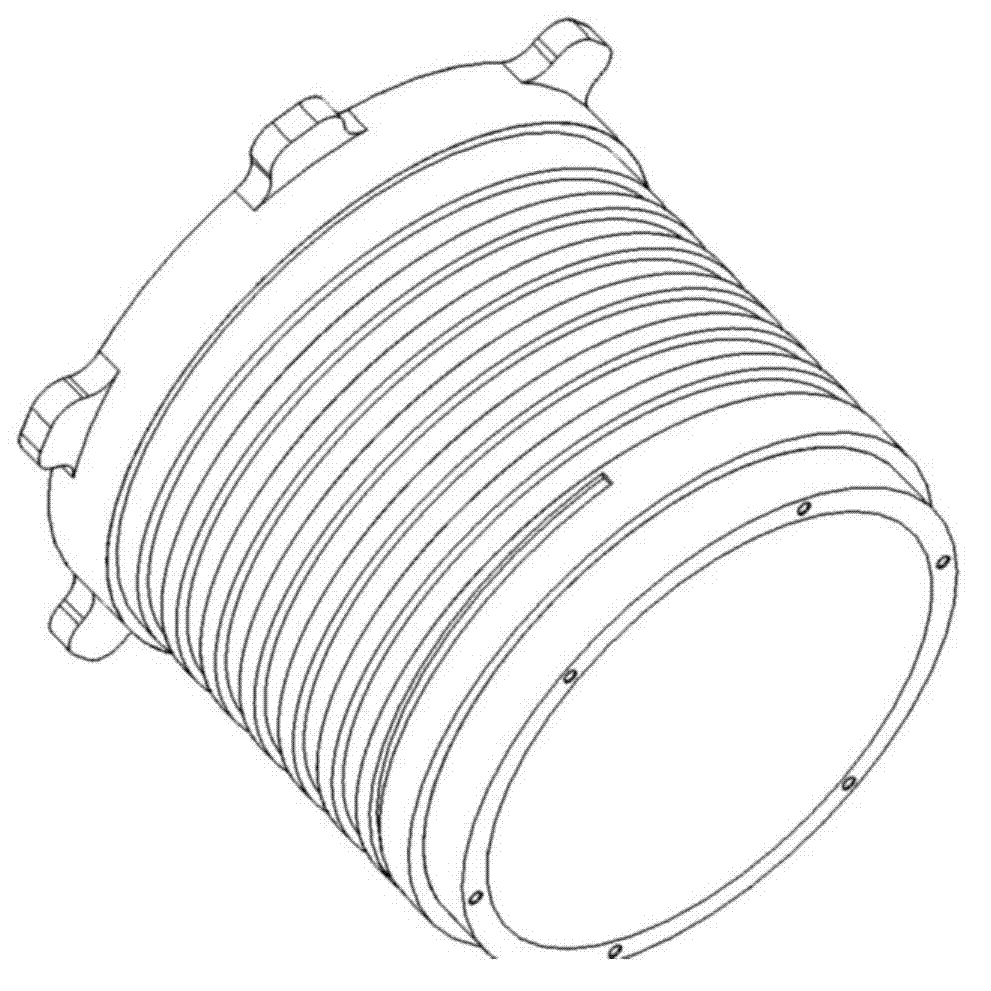

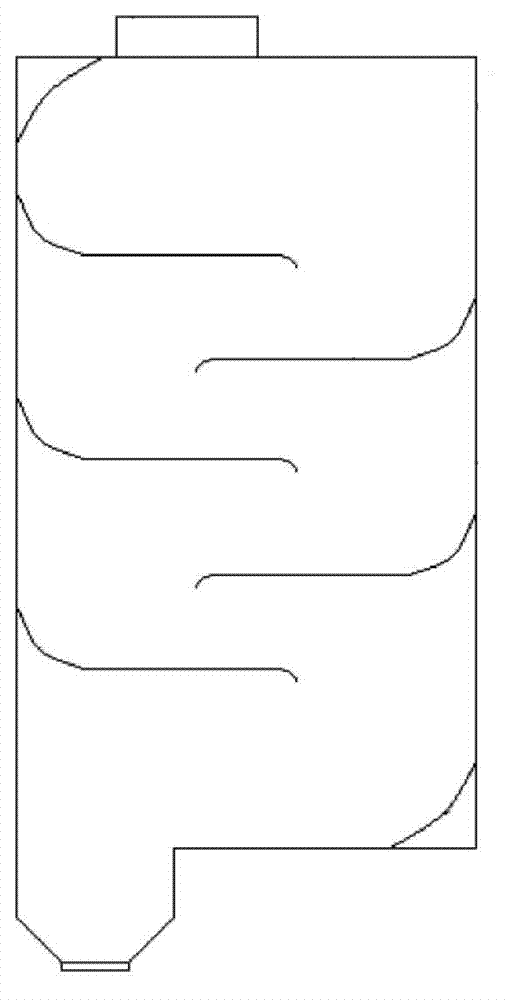

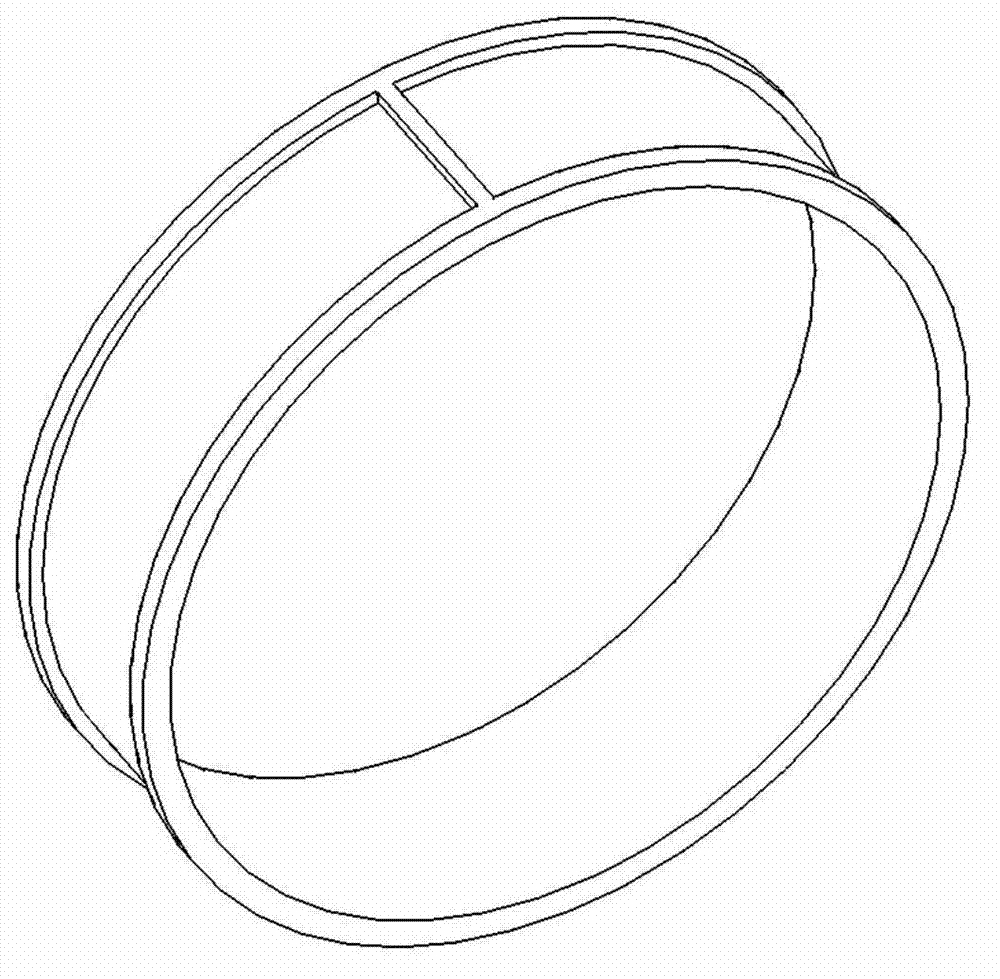

[0029] The water jacket structure used for motor stator cooling provided by the present invention, such as Image 6 As shown, it includes a hollow cylindrical water jacket body 1 and a casing 2. The casing 2 is two arc-shaped shells. The corresponding positions of the plates are formed with a plurality of bolt holes for bolt installation, and the water jacket body 1 has two ribs, and the two ribs are symmetrically distributed around the axis of the water jacket body 1 . One arc-shaped shell is located outside the water jacket body 1 on one side between the two ribs, and the other arc-shaped shell is located outside the water jacket body 1 on the other side between the ribs, and each side of the ribs has a The fixed plate, the two arc-shaped shells are fixedly connected by bolts and nuts, and the ribs in the middle are clamped by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com