Fuse for LED FL retrofit lamp, LED FL retrofit lamp, and methods for producing LED FL retrofit lamp

A technology for LED fluorescent lamps and safety devices, which can be used in emergency protection devices, use of semiconductor lamps, safety devices of lighting devices, etc., and can solve problems such as inability to maintain quality standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

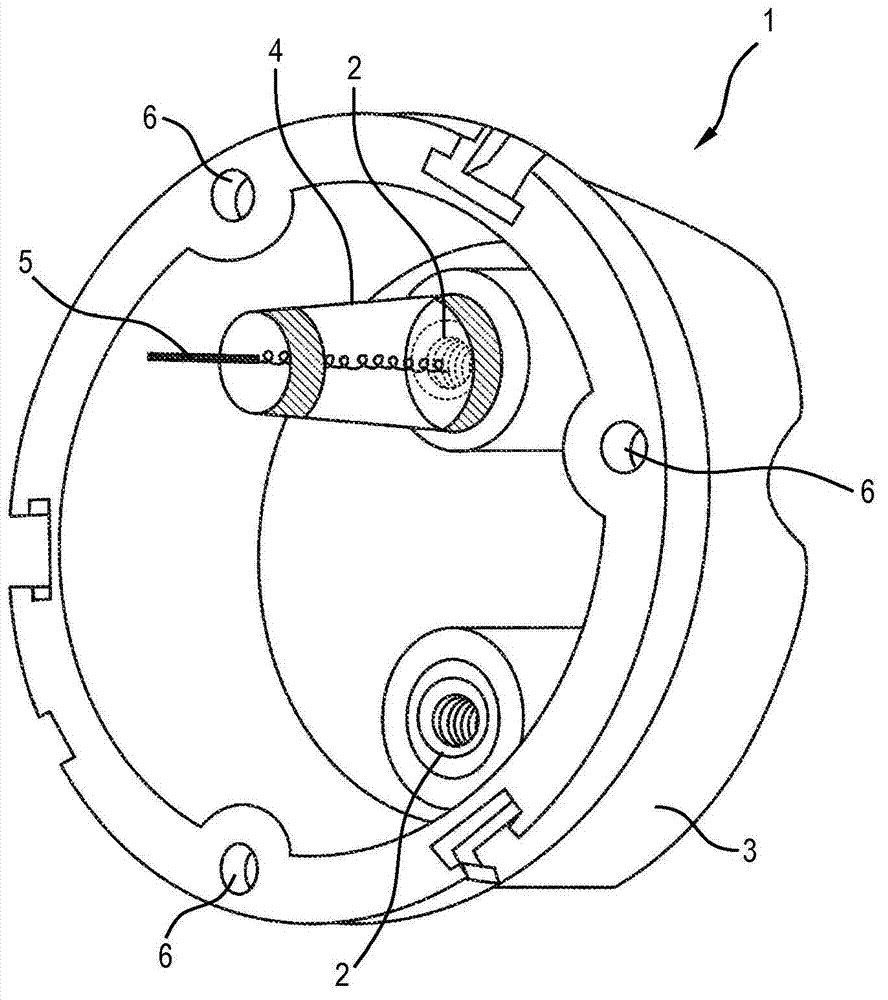

[0026] figure 1 A perspective view on the inner side of a T8-type lamp cap showing an LED fluorescent lamp retrofit lamp. The base 1 can be plugged onto the bulb of the LED fluorescent lamp retrofit lamp by means of the side shown, wherein the driver (not shown) is adjacent to the base 1 in the assembled state. The driver supplies one or more light-emitting diodes (not shown) of the LED fluorescent lamp retrofit lamp and is connected to the lamp base 1 for power supply. The lamp base 1 can also be plugged into a matching lamp socket and has two connection pins 2 in the plastic housing 3 for this purpose.

[0027] On the inner end of the connecting pin 2, the safety device 4 is fixed firmly, so that the driver can contact the connecting wire 5 of the safety device 4 on the one hand and the other of the two connecting pins 2 on the other hand. . Therefore, the safety device 4 is connected in series with the driver.

[0028] The lamp base 1 can be connected with a bulb (not s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com