Measuring point marking device for automatic identification of measuring points in condition monitoring systems

A condition monitoring system and technology of marking device, which are applied in the direction of measuring device, measuring device casing, static/dynamic balance test, etc., can solve the problems of high cost and disadvantage, and achieve the effect of saving space and avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

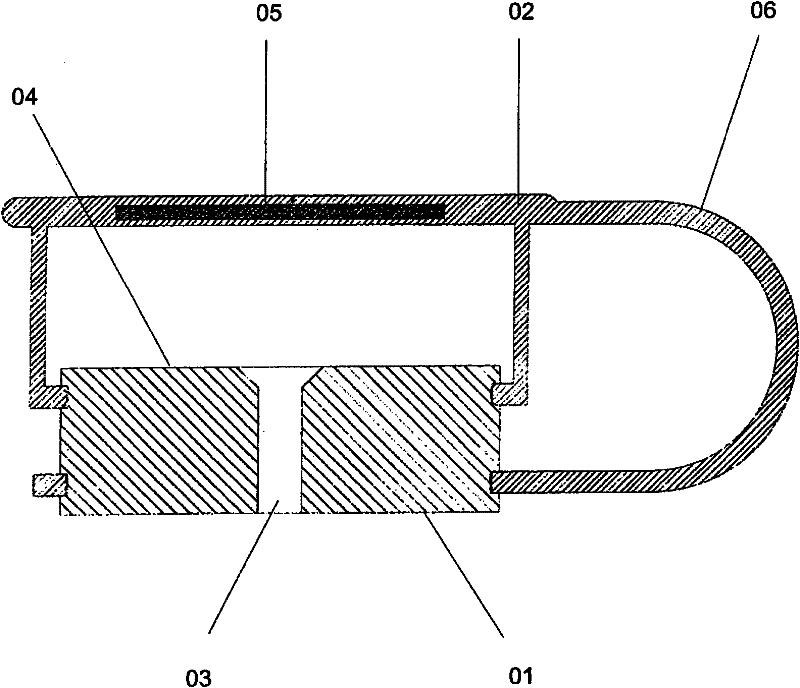

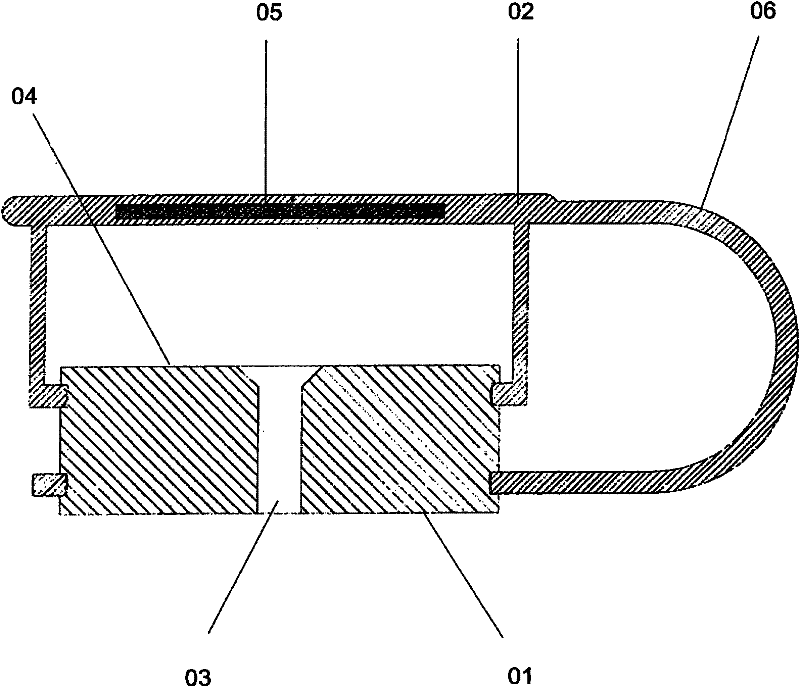

[0026] figure 1 A simplified cross-sectional view of a measuring point marking device according to the invention is shown. The measuring point marking device is used for automatic identification of measuring points in the condition monitoring system, so as to mark the measuring points. The measuring point marking system includes a flat plate 01 and a protective cover 02 connected with the flat plate 01 . The protective cover 02 is designed to cover the tablet 01 in a closed state. This protects the plate 01 from contamination. The plate 01 can be fixedly connected to measuring points on the machine or the like (not shown). This connection can be achieved by, for example, gluing. Bonding has the advantage that no removal of material from the object to be measured takes place, so that a reduction in the strength of the object can be avoided. It is also possible to fix the plate 01 by means of mechanical fasteners, provided that removal of material presents no problems and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com