Measuring assembly for measuring liquids

A measuring device, liquid technology, applied to measuring devices, testing food, instruments, etc., can solve problems such as wrong measurement, and achieve the effect of suppressing induction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

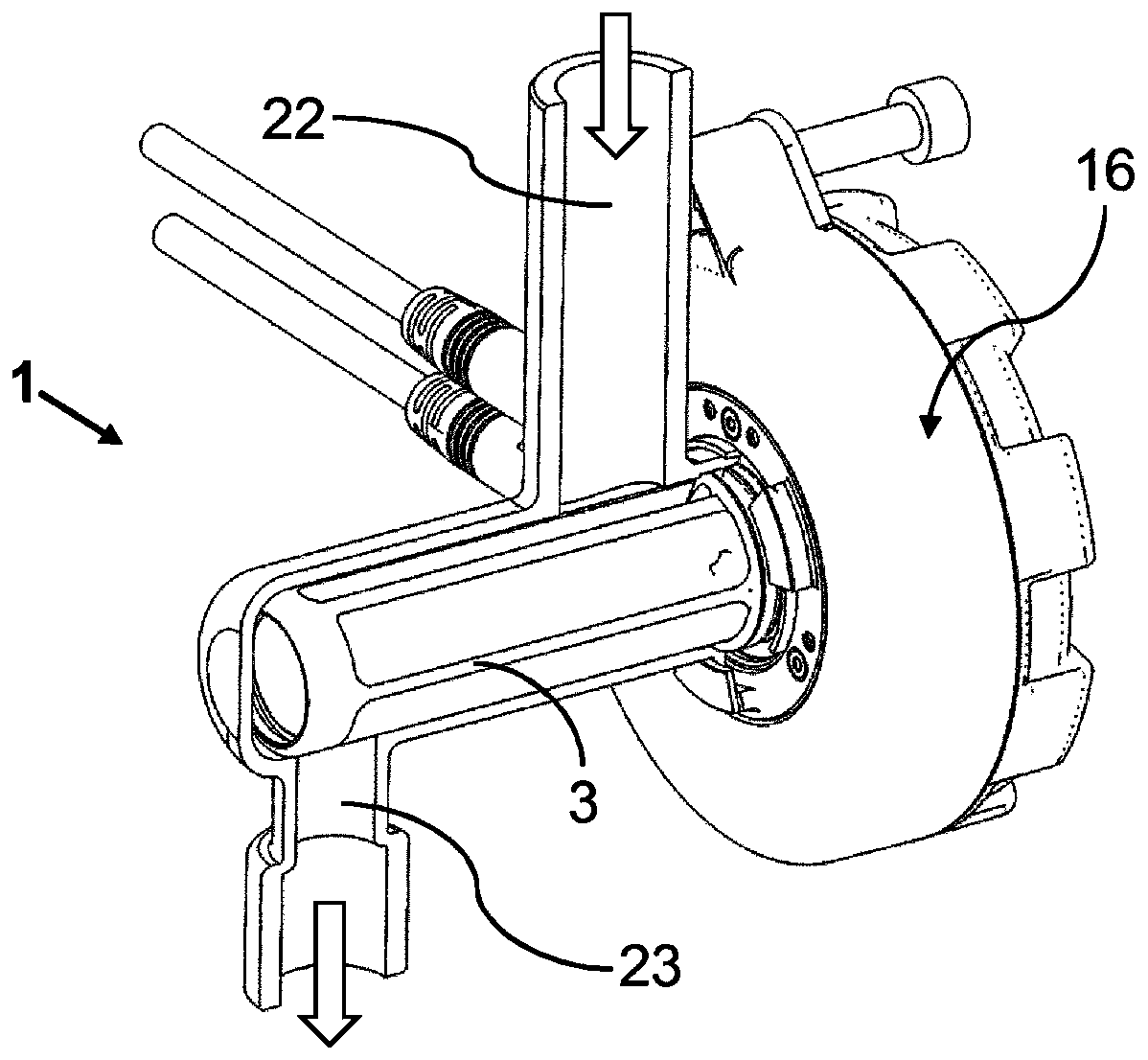

[0043] figure 1 Shown is a measuring device designated overall by 1 for the capacitive measurement of frying oil and / or frying fat. For this purpose, frying oil and / or frying fat are fed to the outer electrode 3 of the measuring device 1 by means of the inflow opening 22 and are discharged therefrom by means of the outflow opening 23 , so that a flow-through measurement takes place.

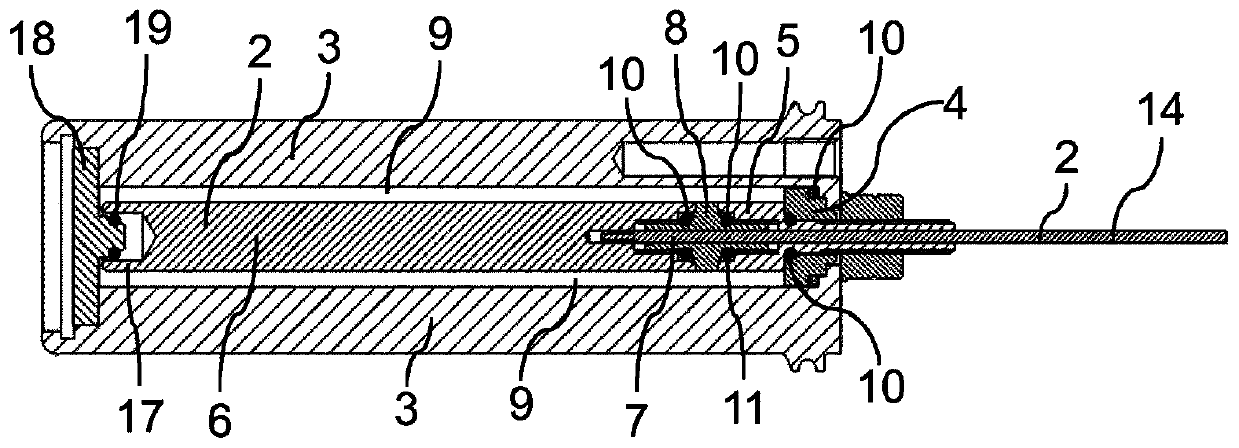

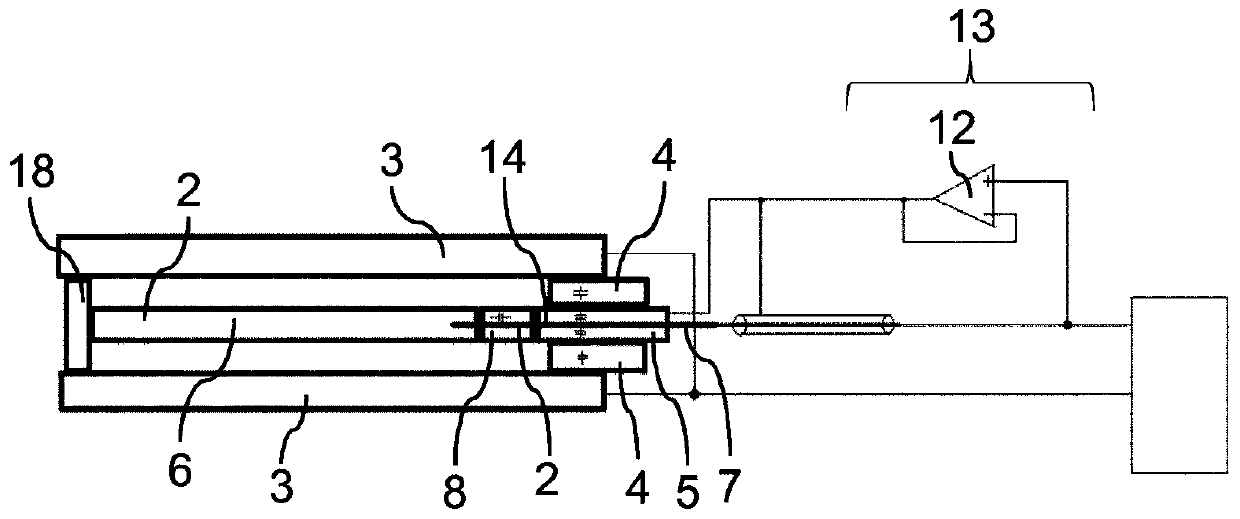

[0044] Such as figure 2 As shown, the external electrode 3 is formed by a cylindrical base body. The inner electrode 2 is arranged at a distance from the outer electrode 3 , the longitudinal axis of which coincides with the longitudinal axis of the outer electrode 3 . The outer electrode 3 therefore surrounds the inner electrode 2 concentrically. A cylindrical measuring gap 9 is formed between the inner electrode 2 and the outer electrode 3 . Frying oil and / or frying fat flow through the measuring gap 9 in the radial direction and in the axial direction (in each case with respect to the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com