Device for cleaning print heads by using ultrasonic waves

A technology of inkjet printing machine and printing head, which is applied in the direction of printing, transfer printing materials, power transmission devices, etc., and can solve the problems of inkjet printing head damage, time cost of printing machine not working, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

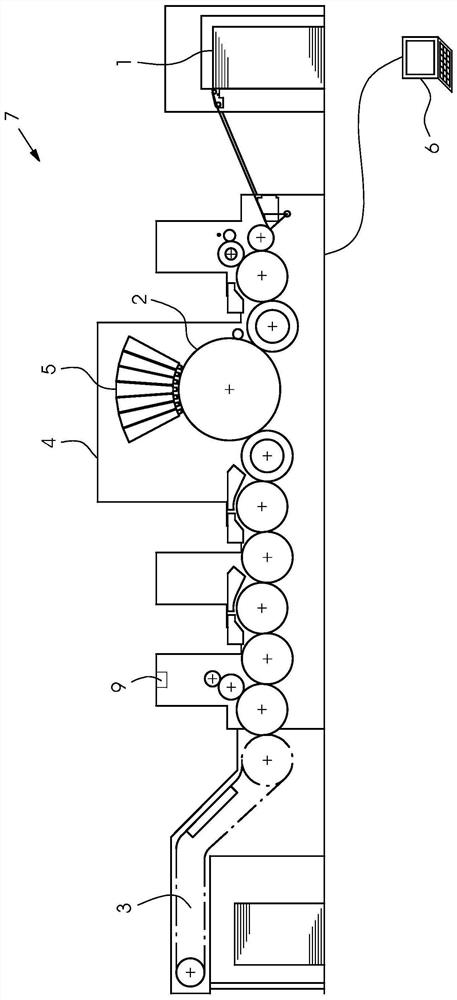

[0024] A preferred field of application for the embodiment variant is an inkjet printer 7 . exist figure 1 is shown as an example of a basic construction for a machine 7 comprising a feeder 1 up to a receiver 3 for feeding a printing substrate 2 into a printing unit 4 in which The printing substrate 2 is printed by a printing head 5 . This is a sheet inkjet printing press 7 , which is controlled by a control computer 6 . During operation of such a printing press 7 , as already explained, individual printing nozzles in the printing head 5 in the printing unit 4 can fail.

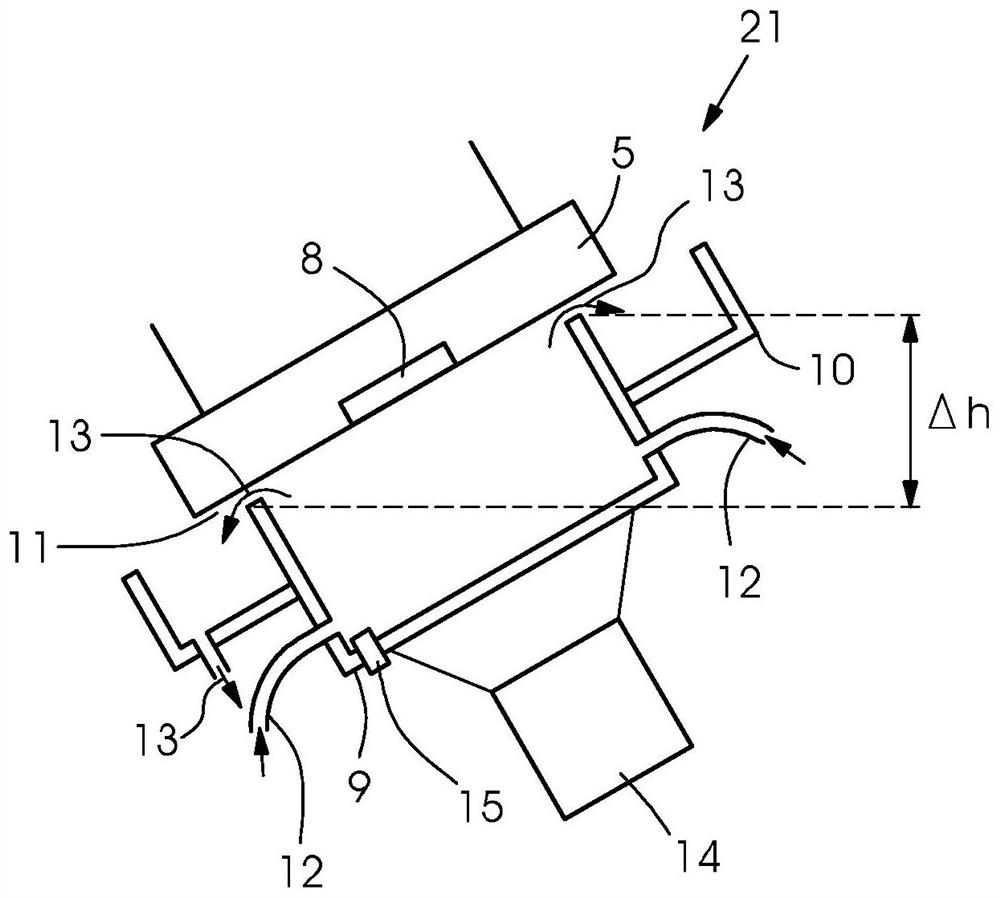

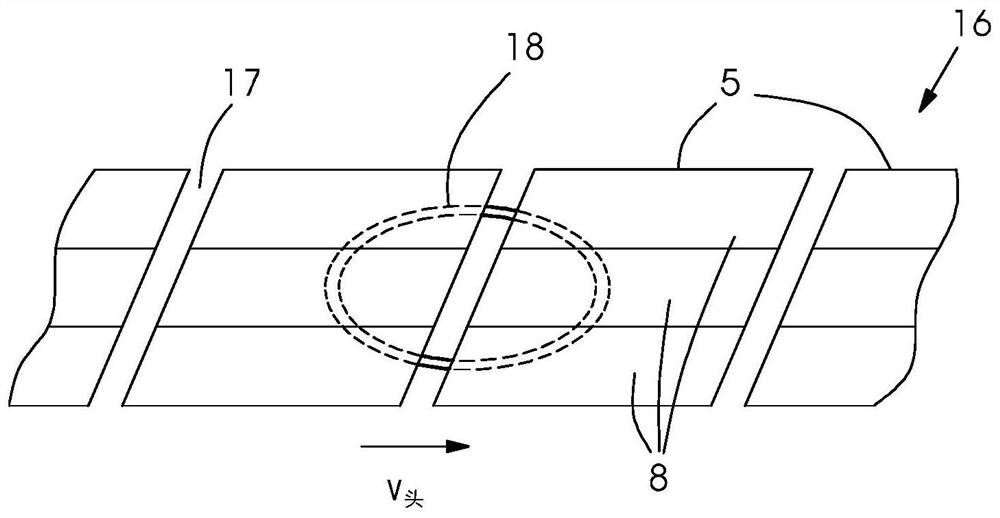

[0025] figure 2A cleaning device 21 according to the invention is shown, which has a cleaning basin 9 filled with cleaning liquid, on which an ultrasonic drive 14 is fastened. The cleaning basin 9 has a precisely defined edge with a defined gap 11 to the surface 18 to be cleaned of the printing head 5 . The basin 9 is continuously supplied with cleaning liquid via the supply line 12 . Depending on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com