Induction cooking device

A technology of induction heating and cooker, applied in induction heating, induction heating device, electric/magnetic/electromagnetic heating, etc., can solve the problem of increasing electrode electrostatic capacitance, reduce heating output, avoid boiling over, and prevent unnecessary the effect of interrupting the cooking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

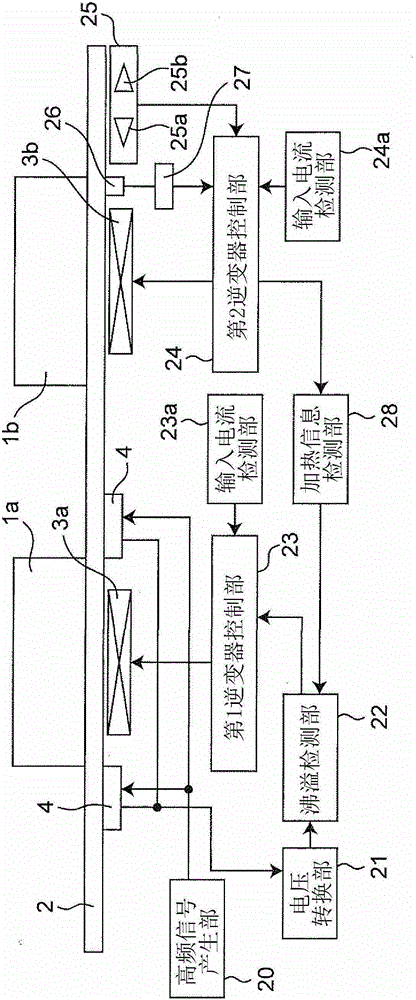

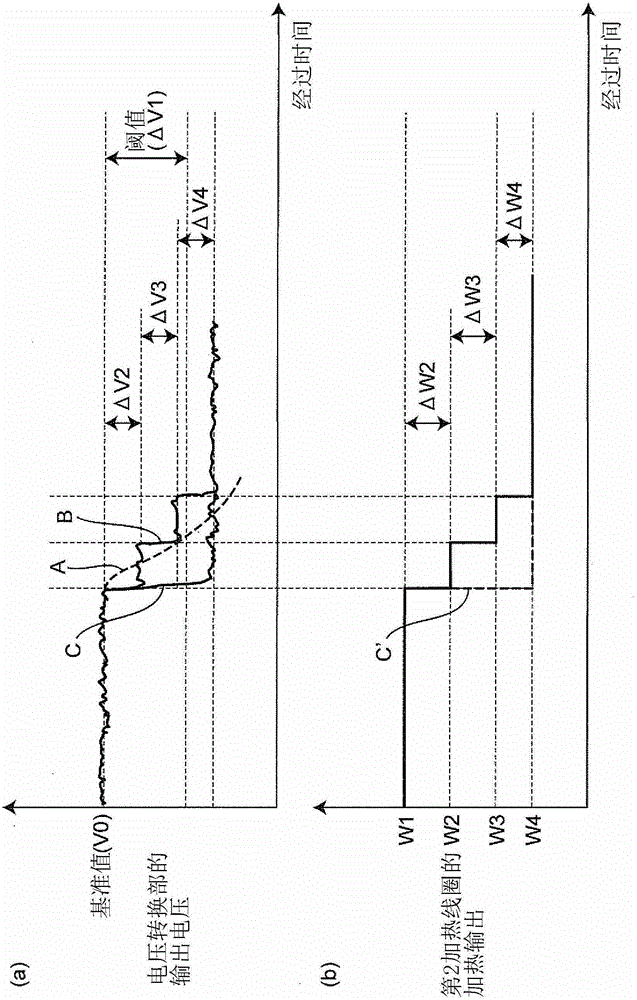

[0042] figure 1 It is a block diagram showing the configuration of the induction heating cooker according to Embodiment 1 of the present invention. figure 2 (a) is a waveform diagram showing the output voltage from the voltage conversion unit to the boiling over detection unit in the induction heating cooker according to Embodiment 1 of the present invention. figure 2 (b) is a waveform diagram showing the heating output of the second heating coil in the induction heating cooker according to the first embodiment.

[0043] exist figure 1 In the induction heating cooker according to Embodiment 1, two heating coils, namely, a first heating coil 3a and a second heating coil 3b, are provided below the top plate 2 constituting the upper outer contour of the induction heating cooker according to Embodiment 1. As the top plate 2 of the induction heating cooker according to Embodiment 1, an example in which crystallized glass is used will be described, but the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com