Stress peening device

A shot peening and spray gun technology is used in explosion generating devices, used abrasive treatment devices, spray guns, etc. It can solve problems such as large deformation of workpieces and uneven coverage, achieve high processing efficiency and improve product quality. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

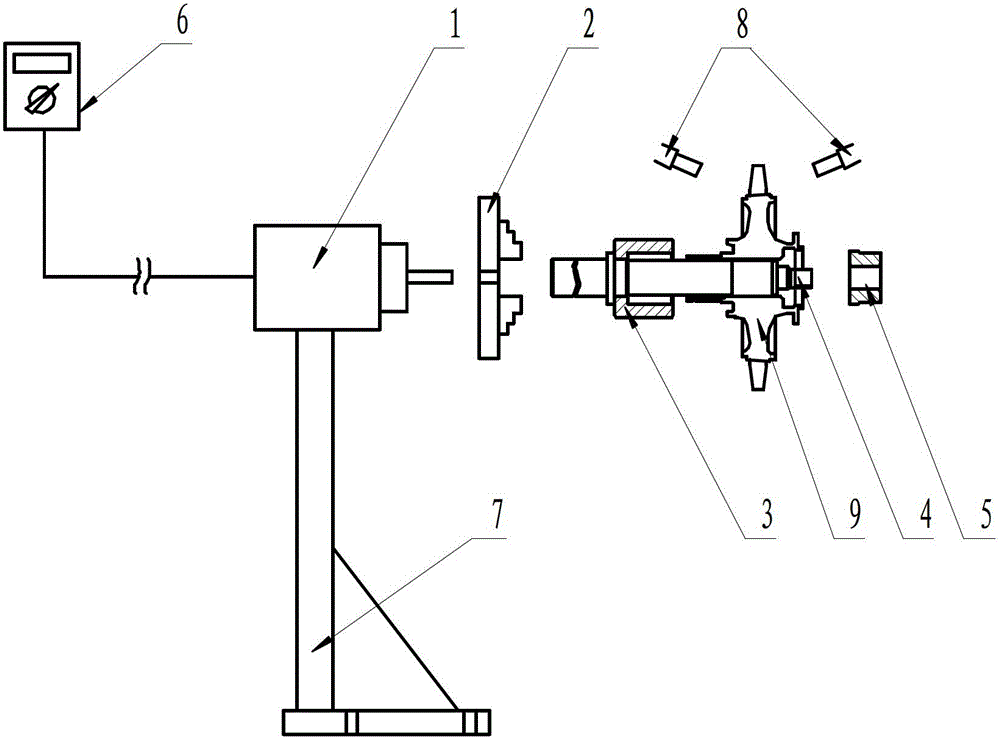

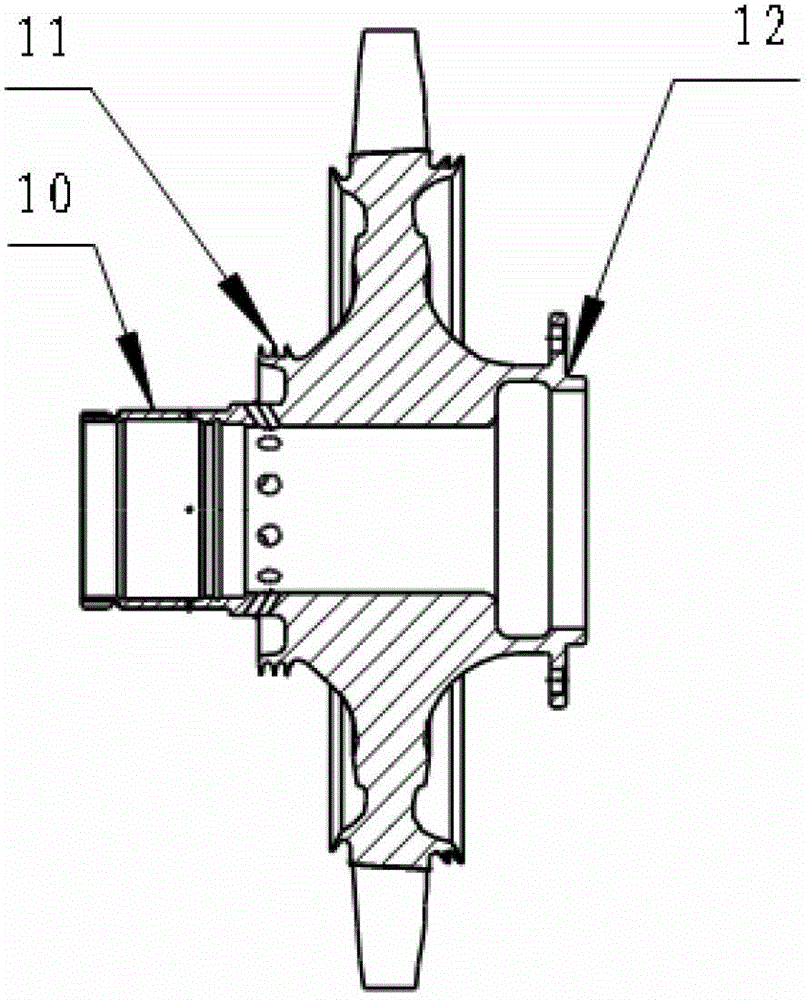

[0030] This embodiment is a vertically rotating double-sided shot peening device, including a motor 1, a workbench 2 with a three-jaw chuck, a front stopper 3, a support rod 4, a rear stopper 5, and a speed regulator 6 And support seat 7. in:

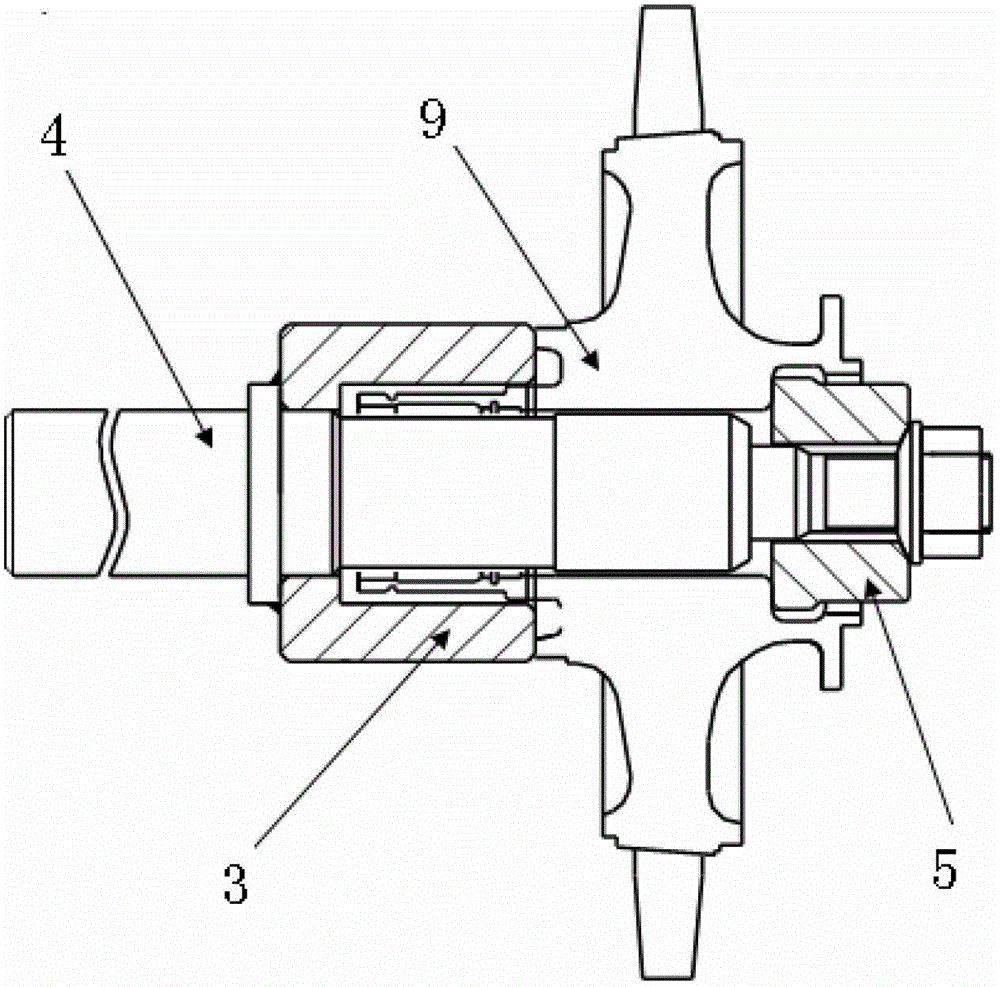

[0031] The motor 1 is fixed on the support base 7 . The workbench 2 is installed on the output shaft of the motor 1, and one surface of the workbench 2 has a three-jaw chuck. One end of the support rod 4 is installed in the three-jaw chuck, and a workpiece 9 is installed at the other end. The front stopper 3 is sleeved on the support rod 4 and located between the worktable 2 and the workpiece 9 , and one end surface of the front stopper 3 is attached to one end surface of the workpiece 9 . The back stop 5 is sleeved on the support rod 4 , and one end surface of the back stop 5 is attached to the other end surface of the workpiece 9 .

[0032] There are 2 spray guns 8, which are fixed on the top of the workpiece 9 at one end of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com