Vehicle body structure for automobile

A body and structure technology, applied in the field of automobile body structure, can solve problems such as easy inward deflection, difficult installation, narrow protrusion width, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

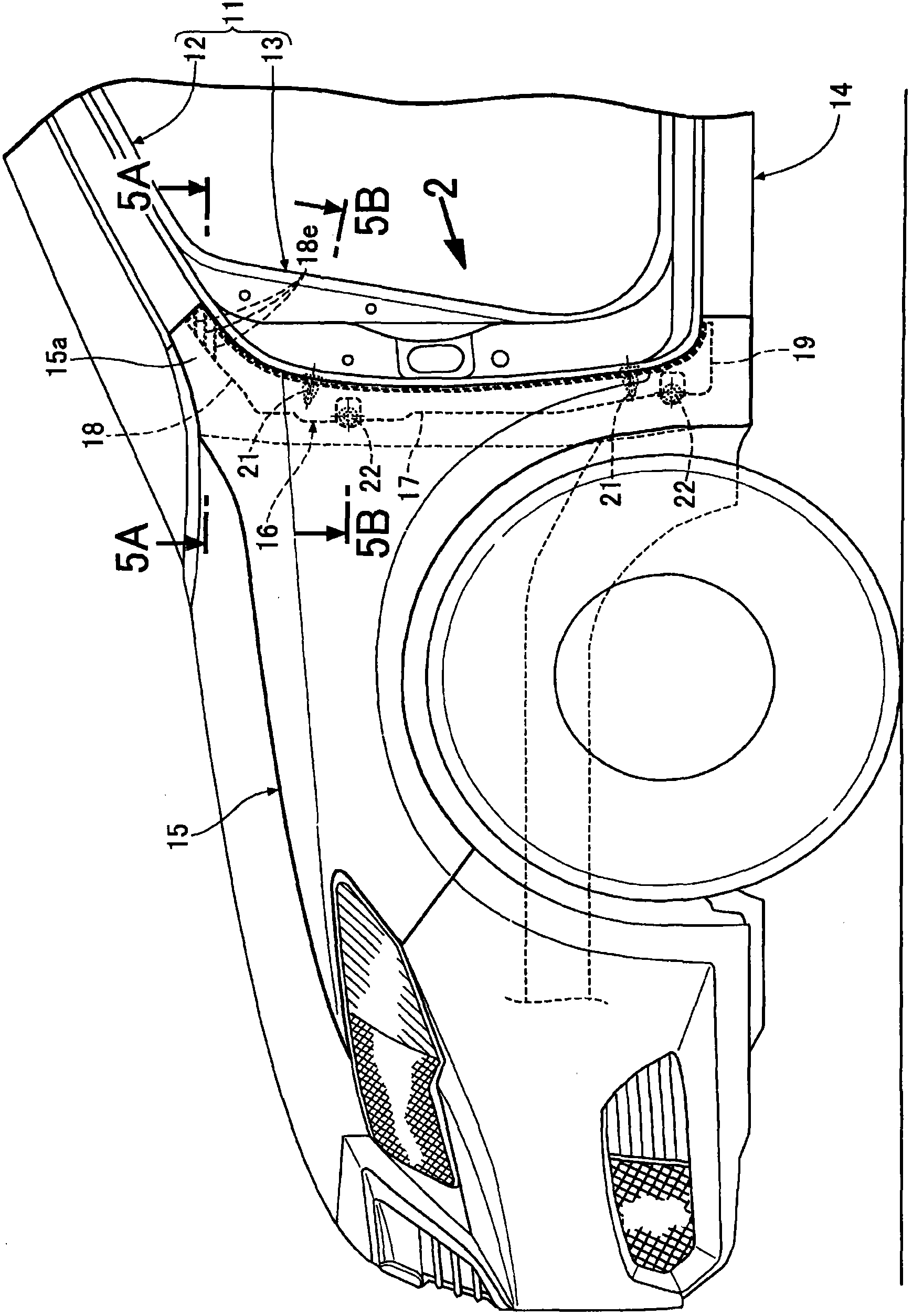

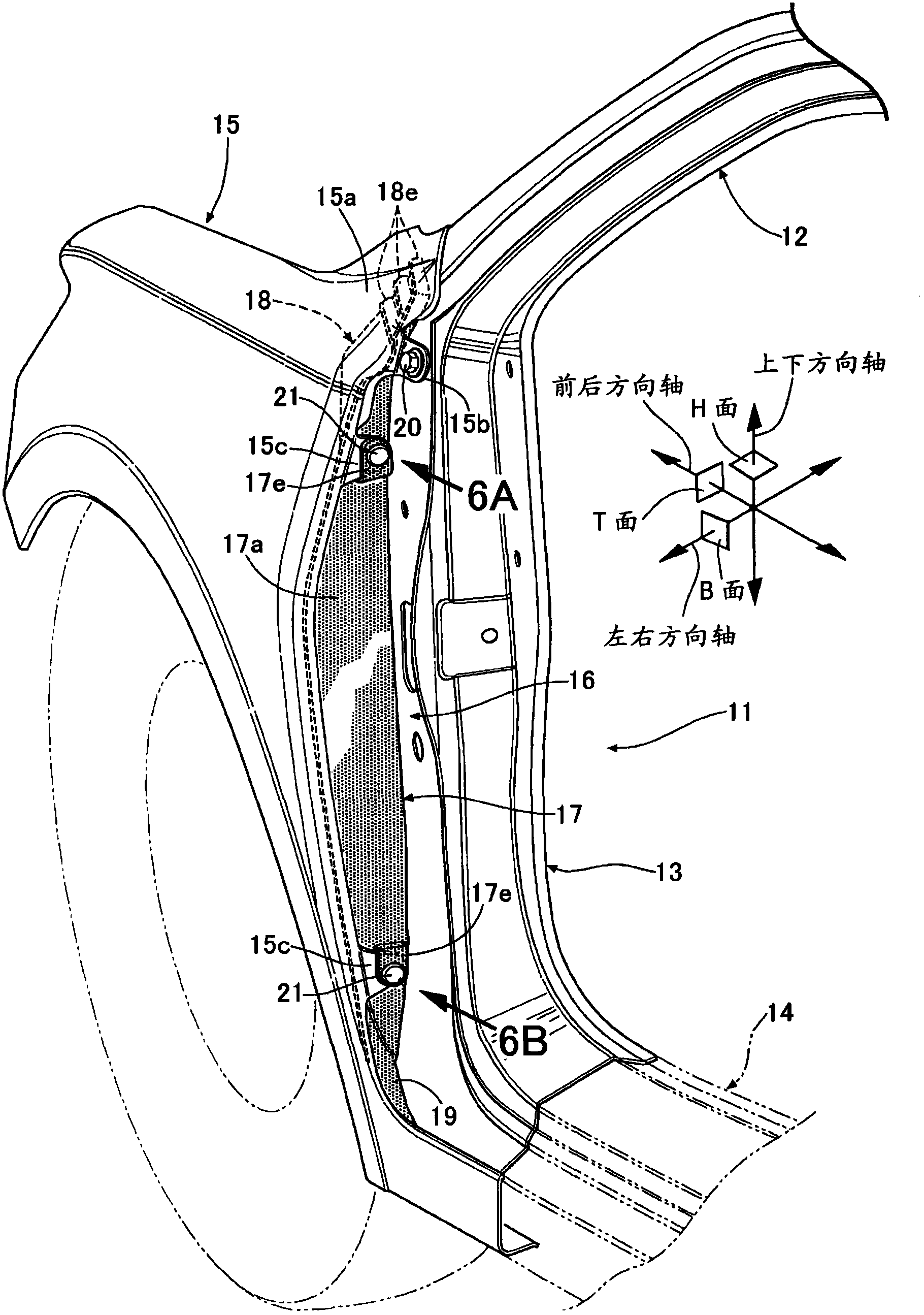

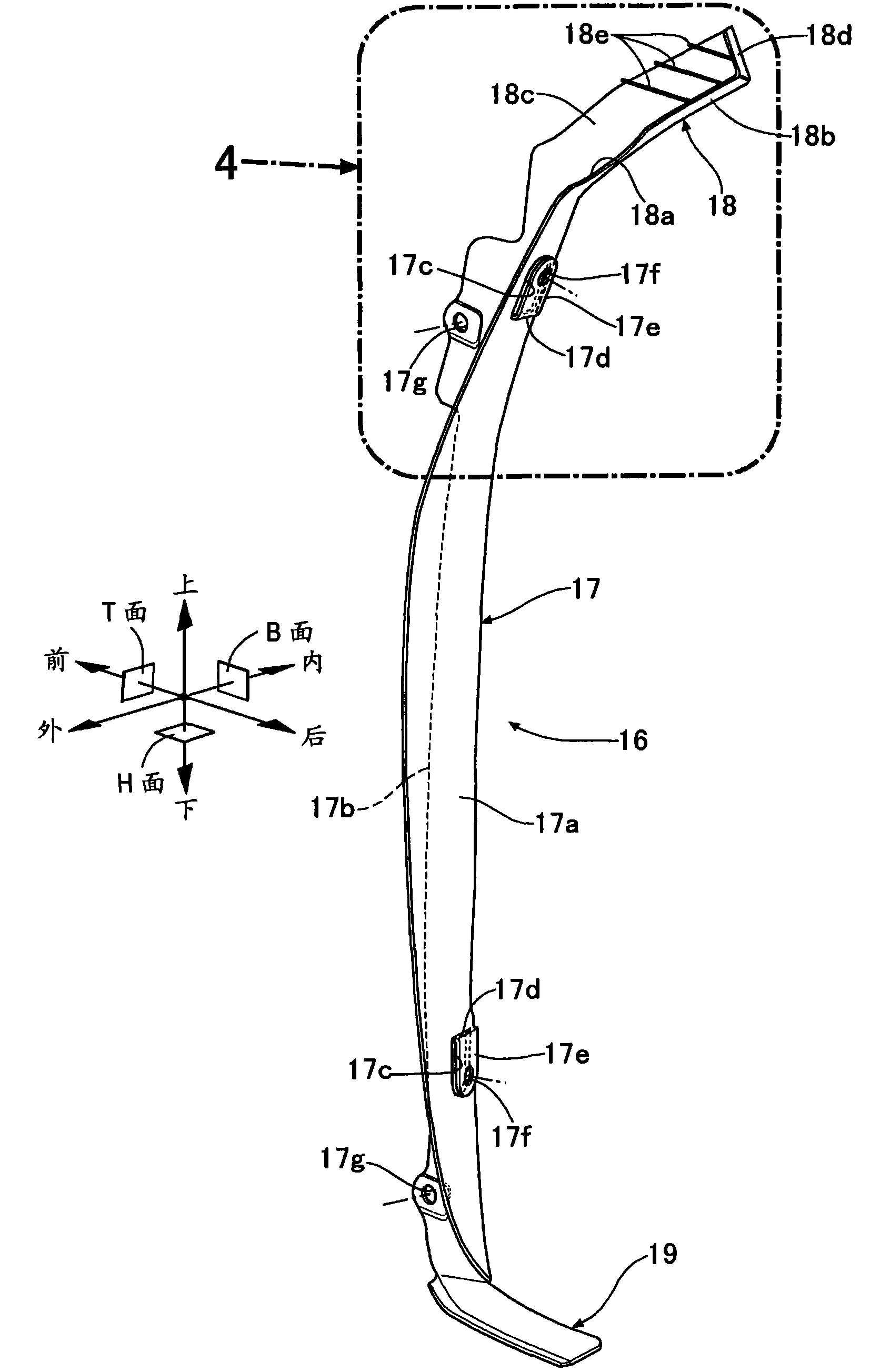

[0049] First, the front-rear direction, the left-right direction (vehicle width direction), and the up-down direction in this specification are defined on the basis of an occupant seated on the driver's seat. In addition, the T surface, B surface, and H surface in this specification are defined as follows. Such as figure 2 As shown, the T surface refers to a surface perpendicular to the front-rear direction axis, for example, the front surface of the vehicle body or the rear surface of the vehicle body corresponds thereto. The B surface refers to a surface perpendicular to the left-right direction axis, for example, the left side of the vehicle body or the right side of the vehicle body corresponds thereto. The H plane refers to a plane perpendicular to the vertical axis, for example, a vehicle body roof surface or a vehicle body bottom surface corresponds thereto. However, the T surface includes a surface inclined at an angle of less than 45° with respect to the surface pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com