Antiskid self-locking rail clamping device for rail mounted gantry crane

A crane and self-locking clip technology, applied in the direction of travel mechanism, load hanging components, transportation and packaging, can solve the problems of life safety mechanical equipment hazards, long-distance slippage, poor braking effect, etc., to ensure that personnel and The effect of property safety, good reliability and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

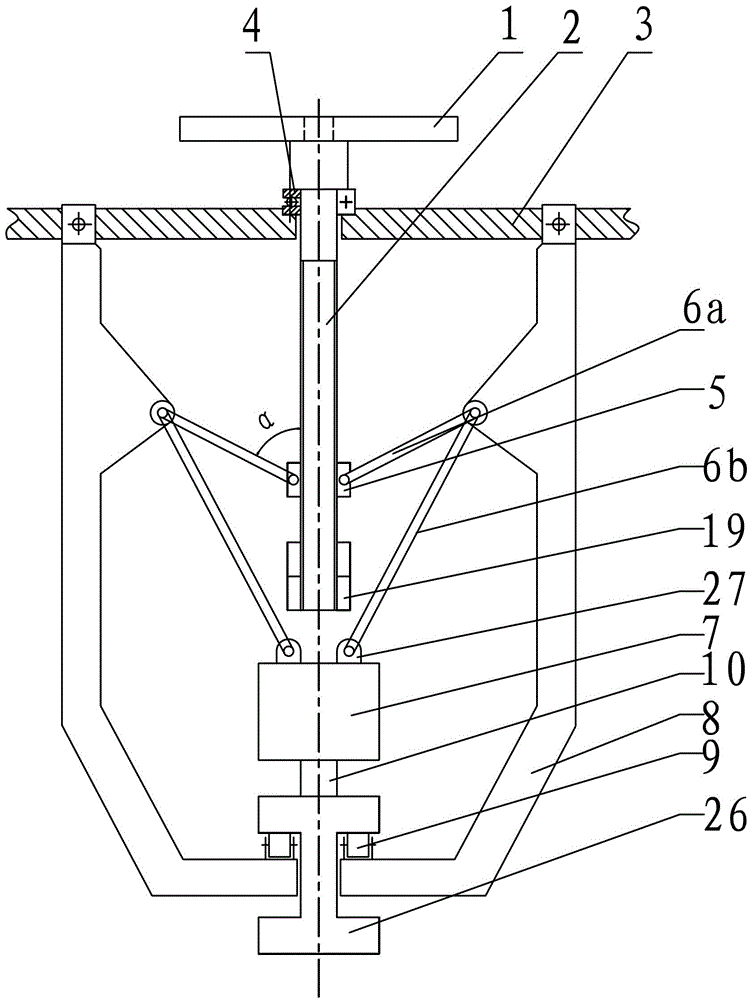

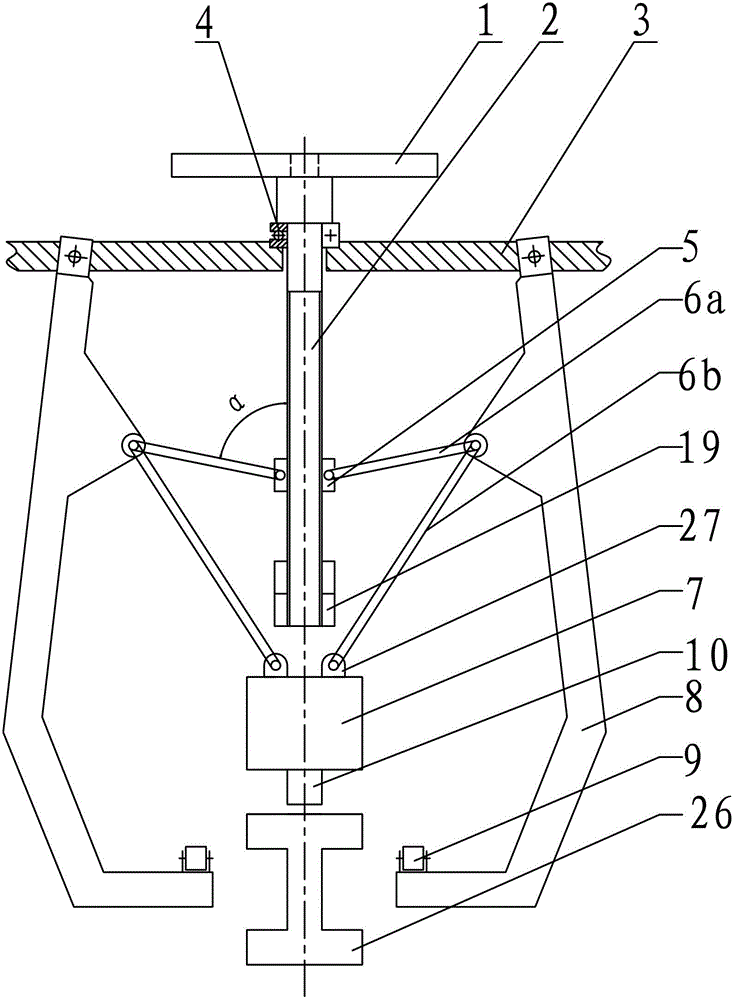

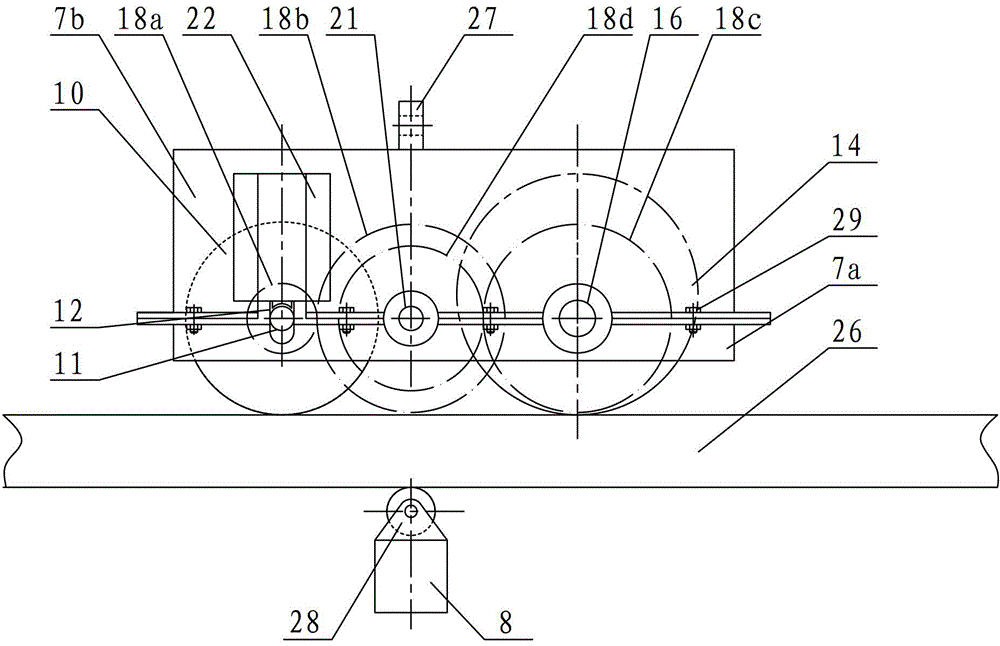

[0024] Such as figure 1 , 2 As shown, this embodiment discloses a rail clamp for a rail gantry crane, including a frame 3, a self-locking screw 2 is provided in the middle of the frame 3, a thrust bearing 4 is arranged between the self-locking screw and the frame, and the self-locking A sliding nut 5 that can move up and down is arranged on the screw rod 2, a limit nut 19 is arranged at the bottom of the self-locking screw rod, and a handle 1 is arranged at the top of the self-locking screw rod. The positions on both sides of the self-locking screw rod on the frame are provided with clamps 8 for clamping the I-shaped track 26 , and the end of the clamps is provided with a lower roller 9 for clamping the lower edge of the upper end surface of the track 26 . A self-locking box 7 with an ear plate 27 is also provided at the position above the rail in the rail clamp. In the link mechanism 6, the two sides of the first connecting rod 6a are respectively hinged with the sliding nu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com