Construction method for integrally jacking and slipping net frame

A technology of integral jacking and construction method, applied in the direction of building, building structure, etc., can solve the problems of high cost of installation measures, single high-altitude slip, long installation period, etc., and achieve flexible construction, saving measures, and good quality control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the content of the invention, features and effects of the present invention, the following embodiments are exemplified and described in detail with the accompanying drawings as follows:

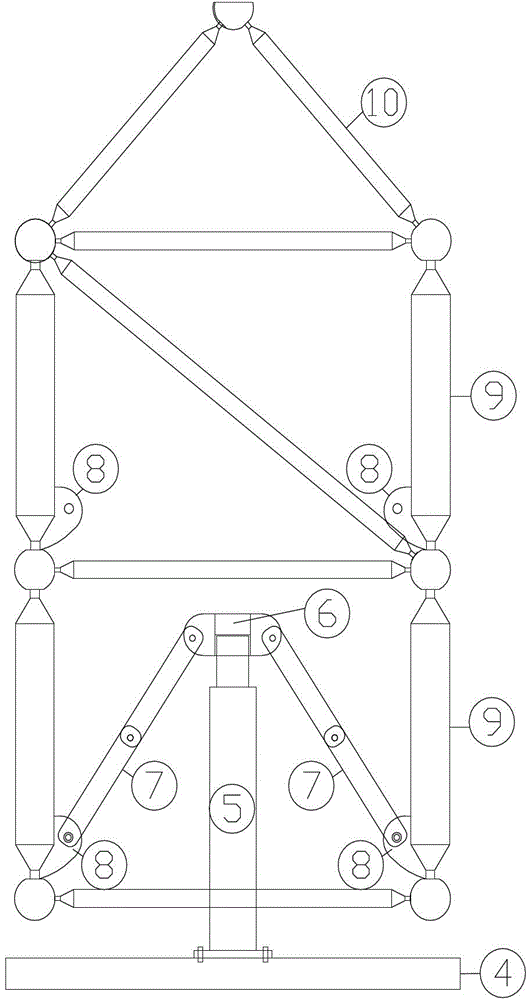

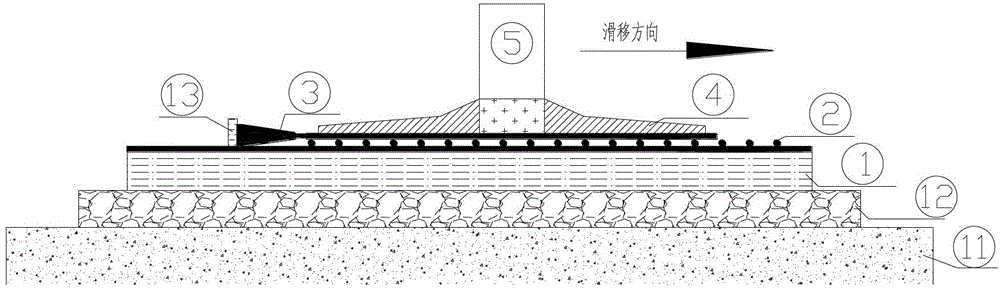

[0025] see Figure 1 to Figure 3 , a construction method for the overall lifting and sliding of a grid frame, comprising the following steps: comprising the following steps:

[0026] 1) The overall lifting of the grid

[0027] After the net frame is assembled on the ground, several sets of jacking devices are evenly arranged in the net frame; each set of jacking devices includes a jacking frame and a jacking hydraulic jack 5, and the jacking frame includes One bolt ball quadrangle 10 and a plurality of bolt ball lattice column standard sections 9, the bolt ball quadrangle 10 is abutted under the steel ball of the grid;

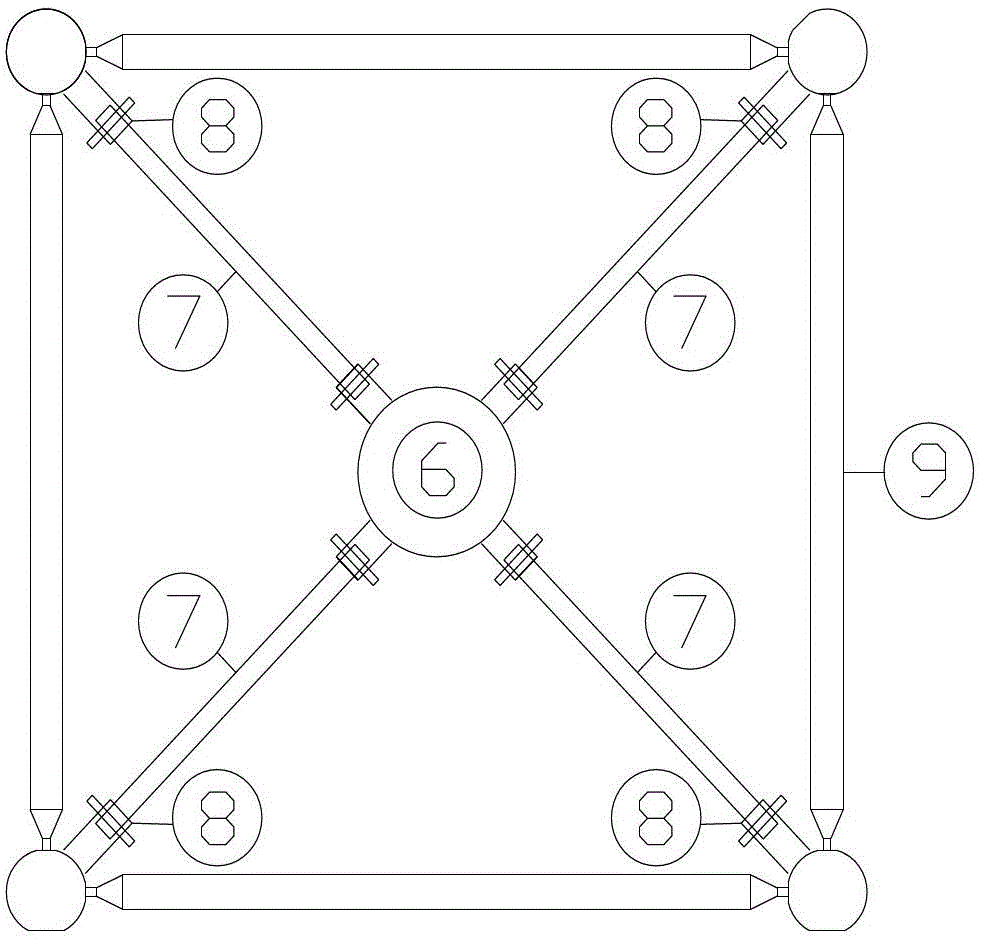

[0028] The top of the jacking hydraulic jack 5 is provided with a jacking cap 6, and the jacking cap 6 is connected with the standard ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com