Molten metal stirring method

A technology of molten metal and stirring method, applied in the field of metallurgy, can solve the problems of insufficient stirring force, affecting the purity of molten metal, and high cost of vacuum stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

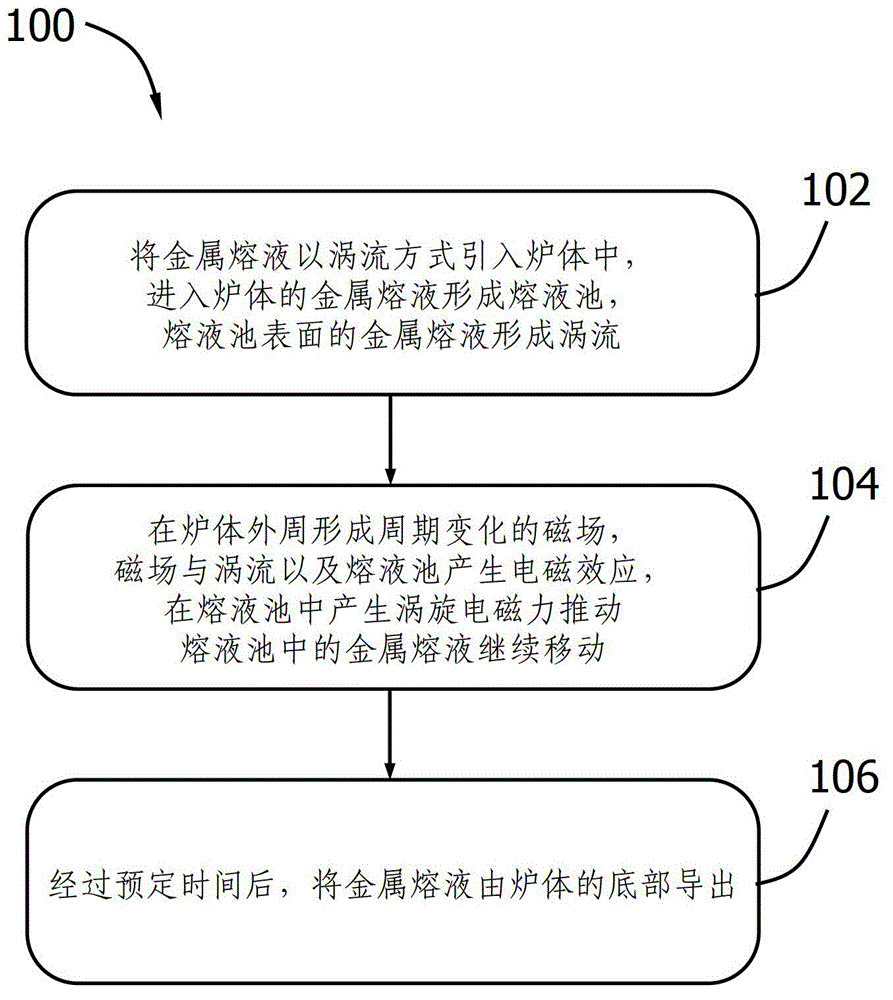

[0012] First refer to figure 1 As shown, the present invention discloses a stirring method 100 of molten metal, which comprises the following steps:

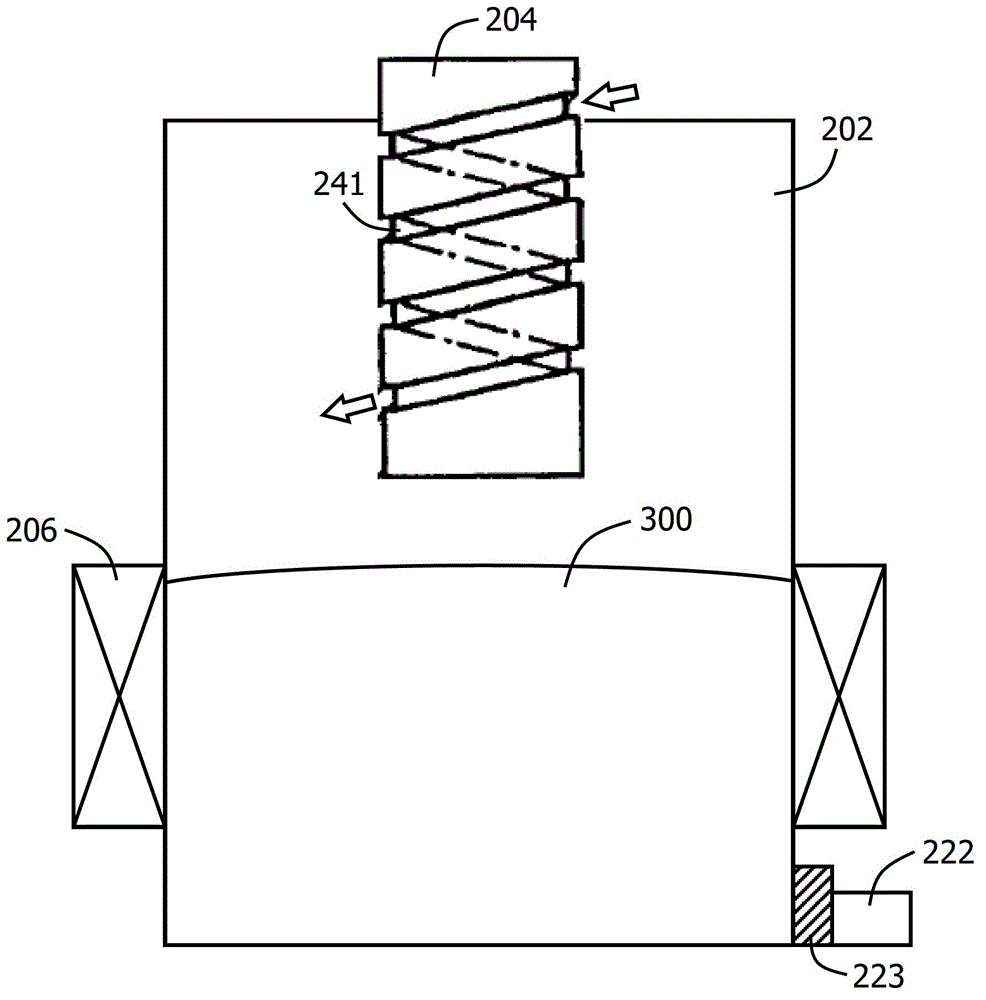

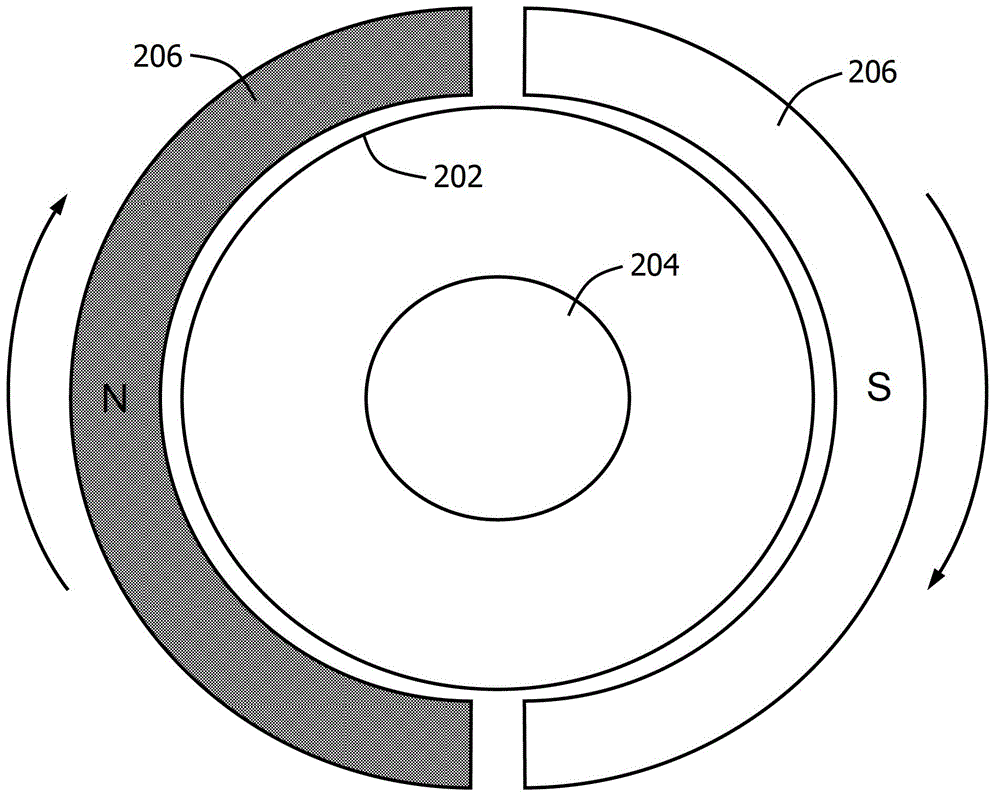

[0013] 102. The molten metal is introduced into the furnace body in an eddy current manner, the molten metal entering the furnace body forms a molten pool, and the molten metal on the surface of the molten pool forms an eddy current. In one embodiment, the implementation of step 102 to enter the molten metal into the furnace body in a vortex mode is to guide the molten metal to pass through a swirl introducer, the swirl introducer is cylindrical, and the surface of the swirl introducer has a spiral opening. The molten metal enters from the inlet of the helical groove at the top of the swirl introducer, and flows out from the outlet of the helical groove at the bottom of the swirl introducer through the helical groove. The molten metal passing through the helical groove forms a vortex in the furnace body. The furnace body is cy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com