Method of Operating an Operator Control and Monitoring Device for Safety-Critical Applications

A key application and observation device technology, applied in the field of operation-and observation devices used to operate safety-critical applications, can solve the problems of machine operators' physical and life injuries, hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

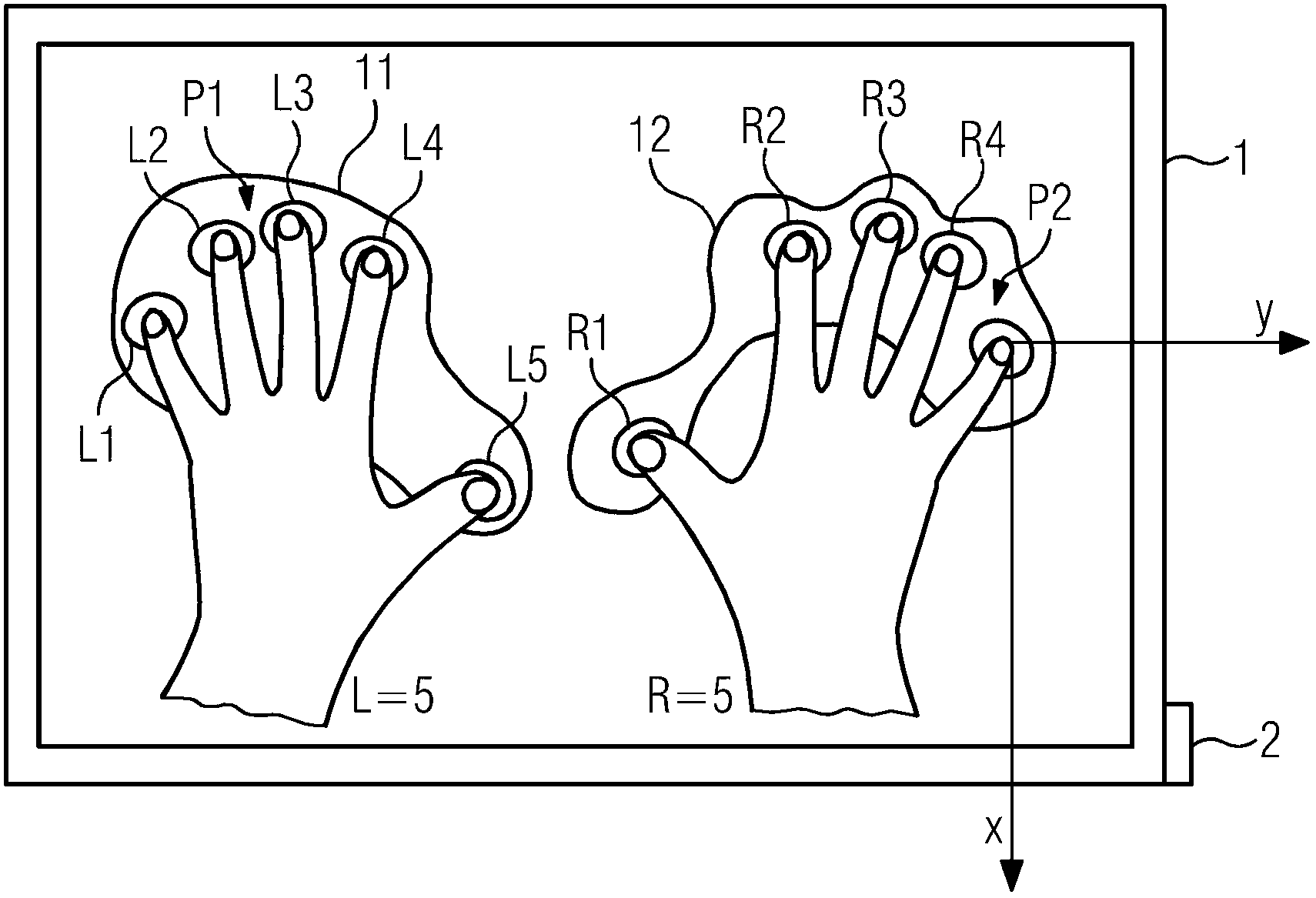

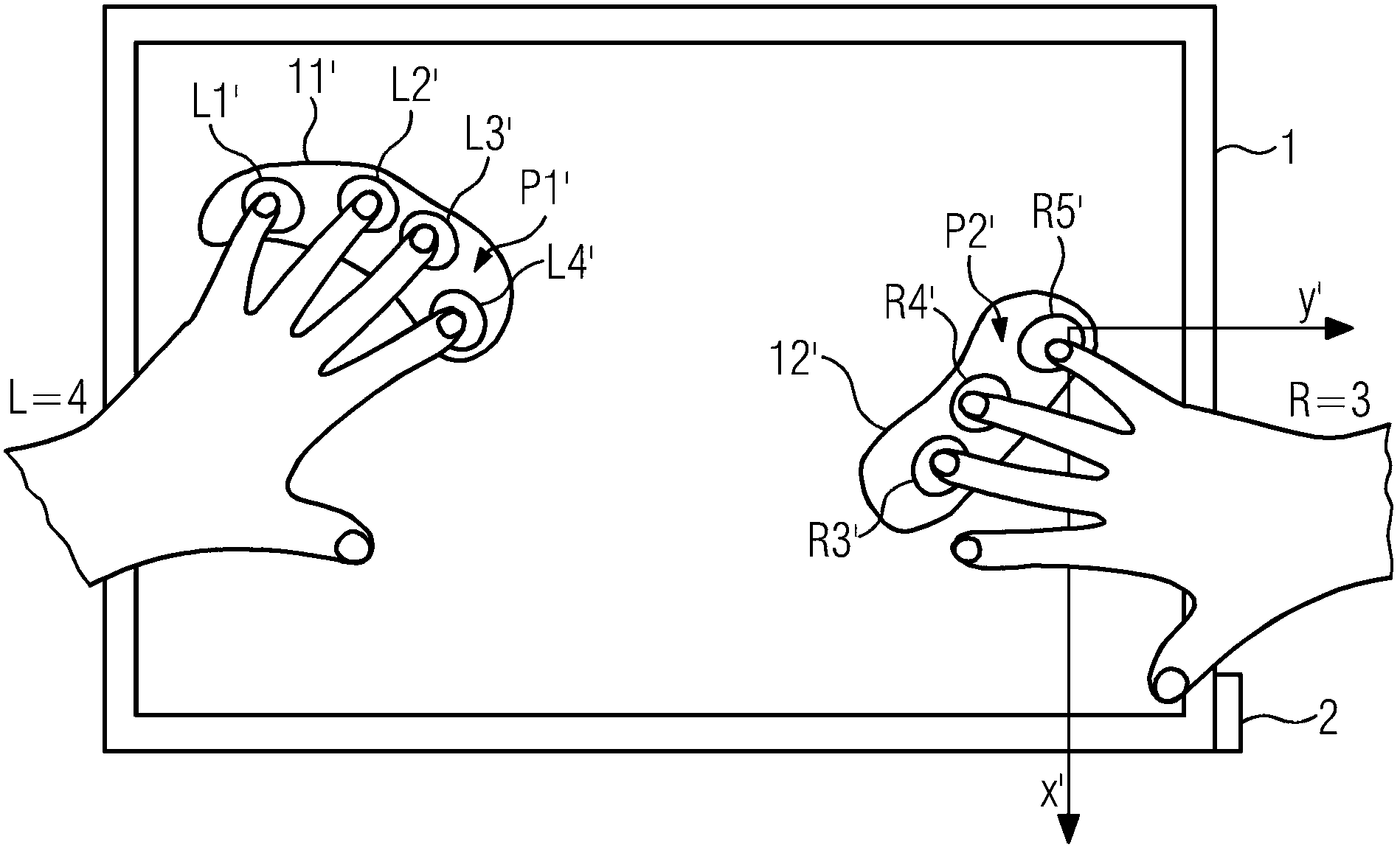

[0013] according to figure 1 , shows an operating and viewing device 1 having a display, for example an LCD display, and a touch-sensitive sensor, for example a resistive multi-touch sensor, arranged in front of it.

[0014] In this case, the graphic software for controlling the display and analyzing the touch of the touch-sensitive sensor is designed in such a way that the operating element is divided into a first operating area 11 and a second operating area 12 for enabling safety-critical applications, wherein in this second A first number L of five touch points L1, . . . Two quantity R. Wherein, the position data P1 of the first operation area 11 and the position data P2 of the second operation area 12 are selected in this way, that is, for example, touch all touch points L1, . . . , L5 of the first operation area simultaneously with multiple fingers of the left hand and all touch points R1, . . . Only when R1, ..., R5 are touched, the opening of the safety-critical app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com