Pressurizer baffle plate and pressurized water reactor (PWR) employing same

A pressurized water reactor and baffle technology, which is applied in the technical field of nuclear reactors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

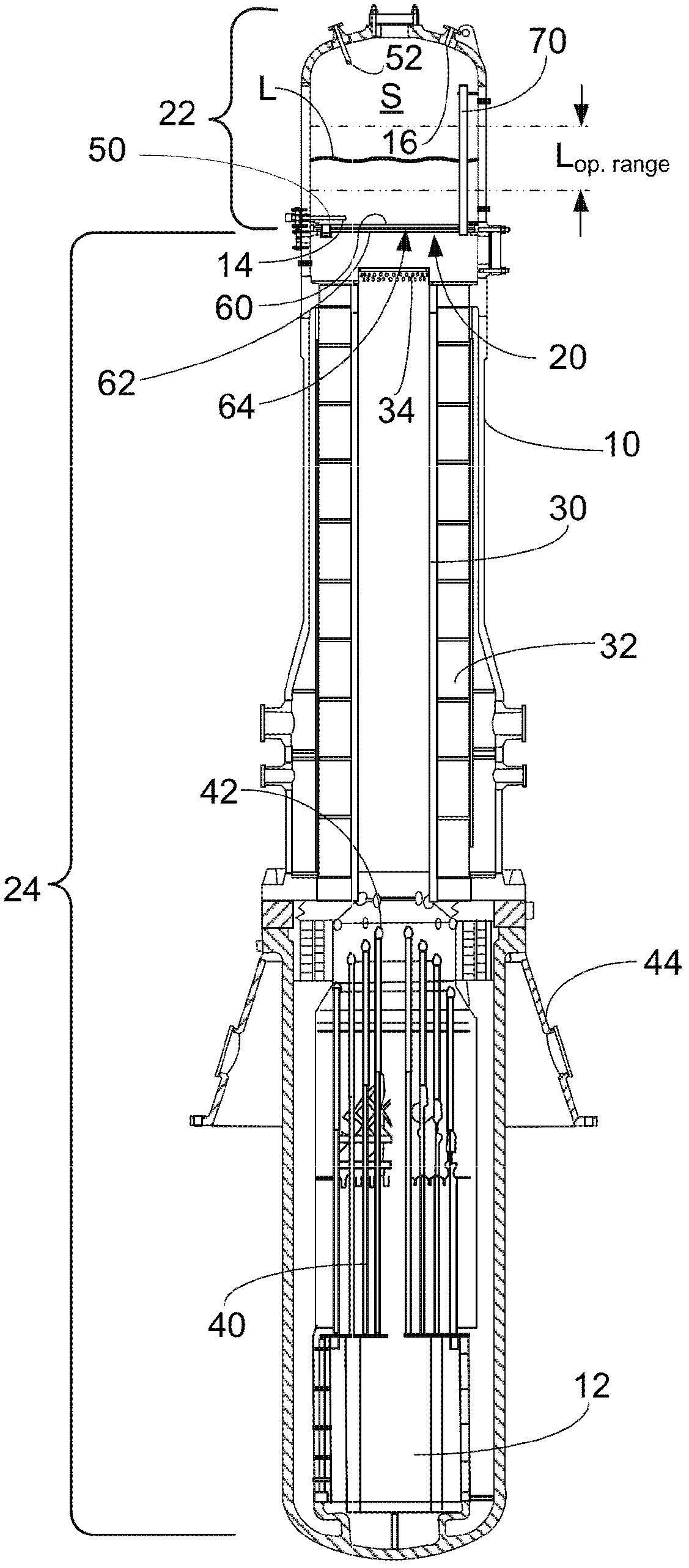

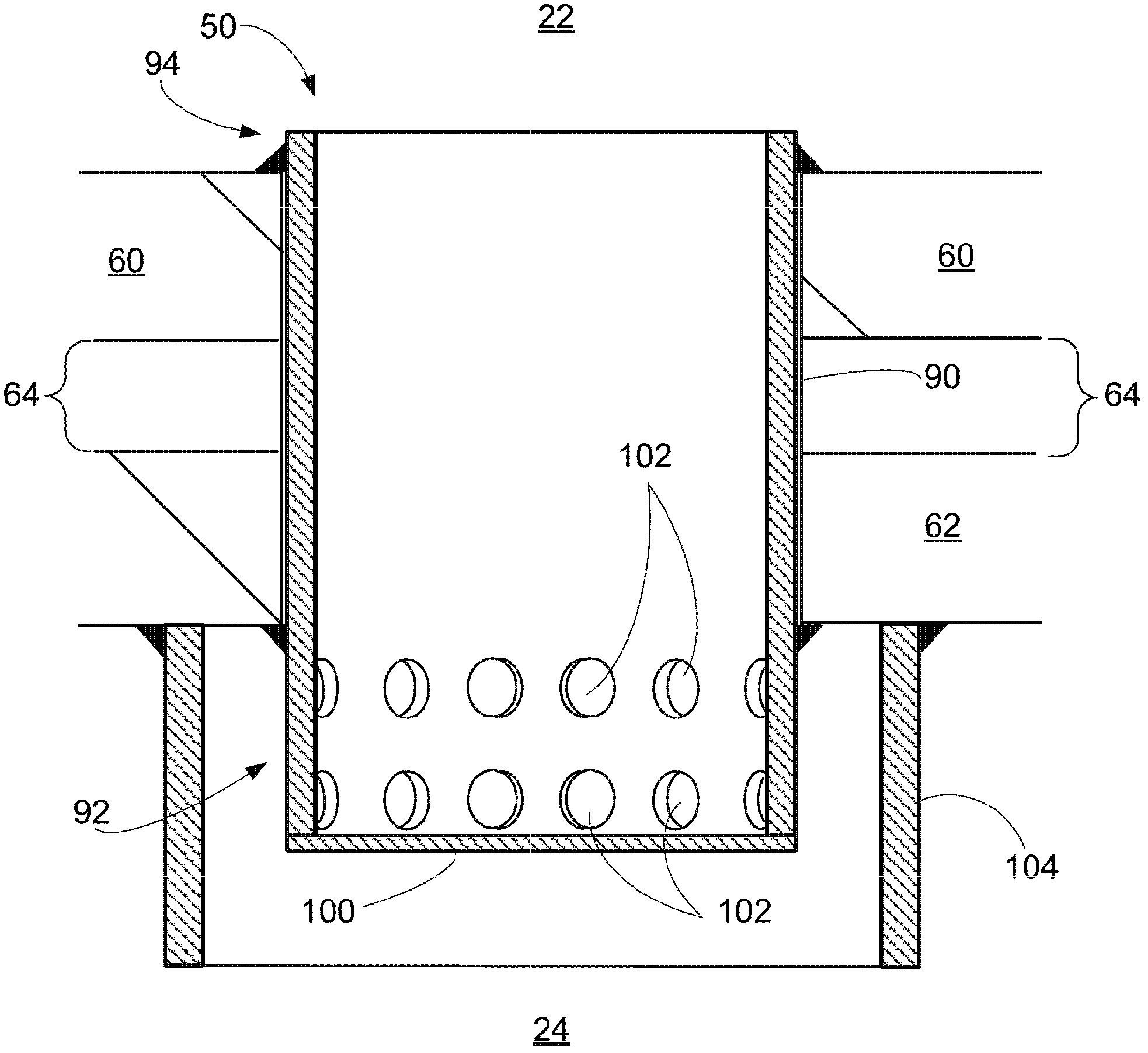

[0014] refer to figure 1 , the illustrated pressurized water reactor (PWR) type nuclear reactor includes a pressure vessel 10 and a nuclear reactor core 12 disposed in the pressure vessel 10 . The reactor core 12 contains large quantities of fissile material, such as those containing uranium dioxide (UO 2 ) material, which is fissile 235 U isotopically enriched products, fissile material arranged as fuel bundles etc. disposed within caged fuel element racks or other support assemblies configured to fit within suitable mounting brackets or securing structures of the pressure vessel 10.

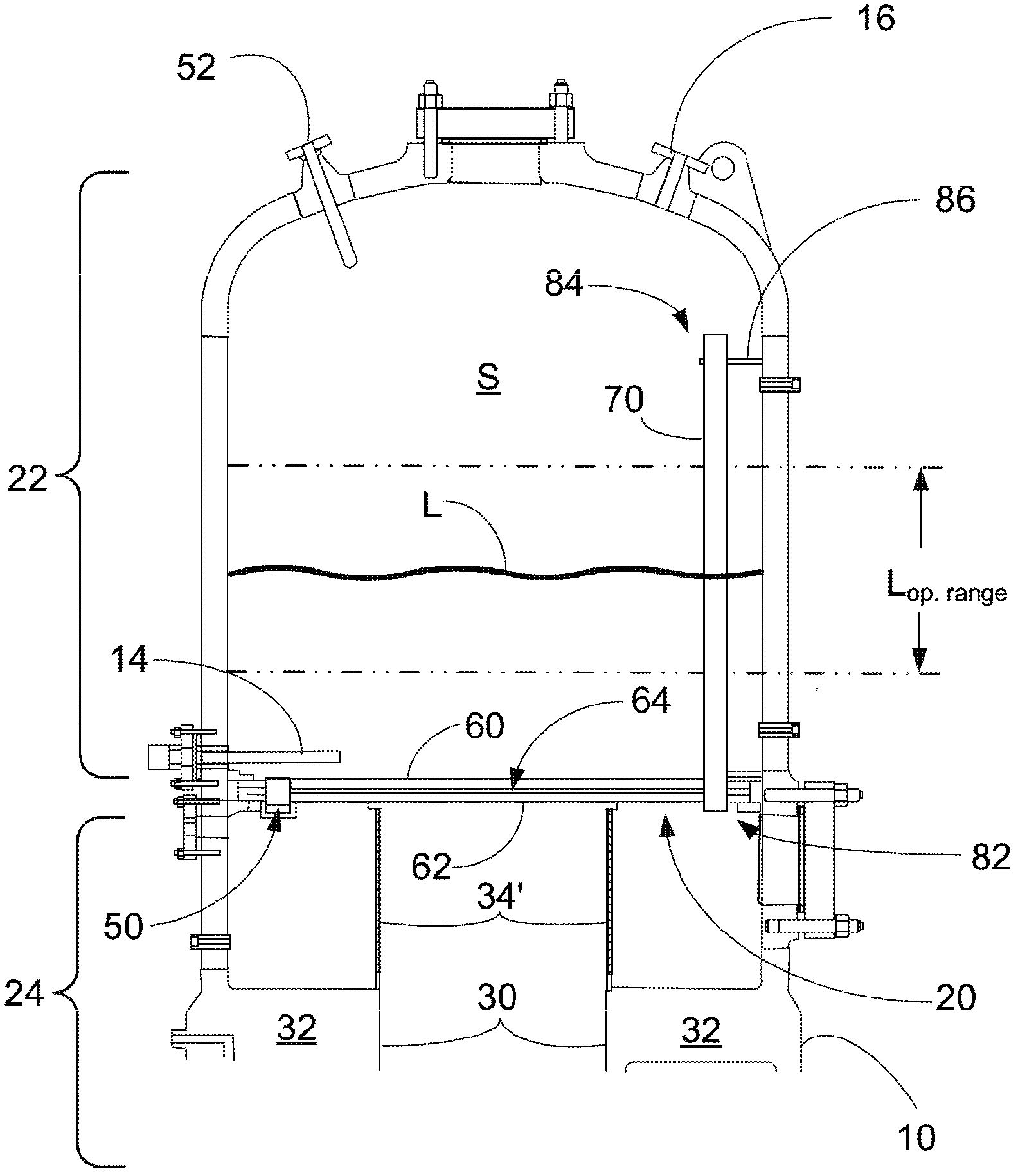

[0015] Pressure vessels containing up to figure 1 Primary coolant at level L indicated. In a PWR configuration, the primary coolant is maintained in a superheated state where both pressure and temperature are controlled. exist figure 1 In the PWR shown, the pressure is maintained using an internal pressurizer comprising steam bubbles S placed at the top of the pressure vessel 10 . A resis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com