Fluid-sealing electric motor connector and motor

A connection plug and fluid sealing technology, applied in the direction of connection, connection component installation, connection device components, etc., can solve the problems of high cost, circuit board damage, and cost of tightening process, and achieve economical cost and eliminate sealing problems. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

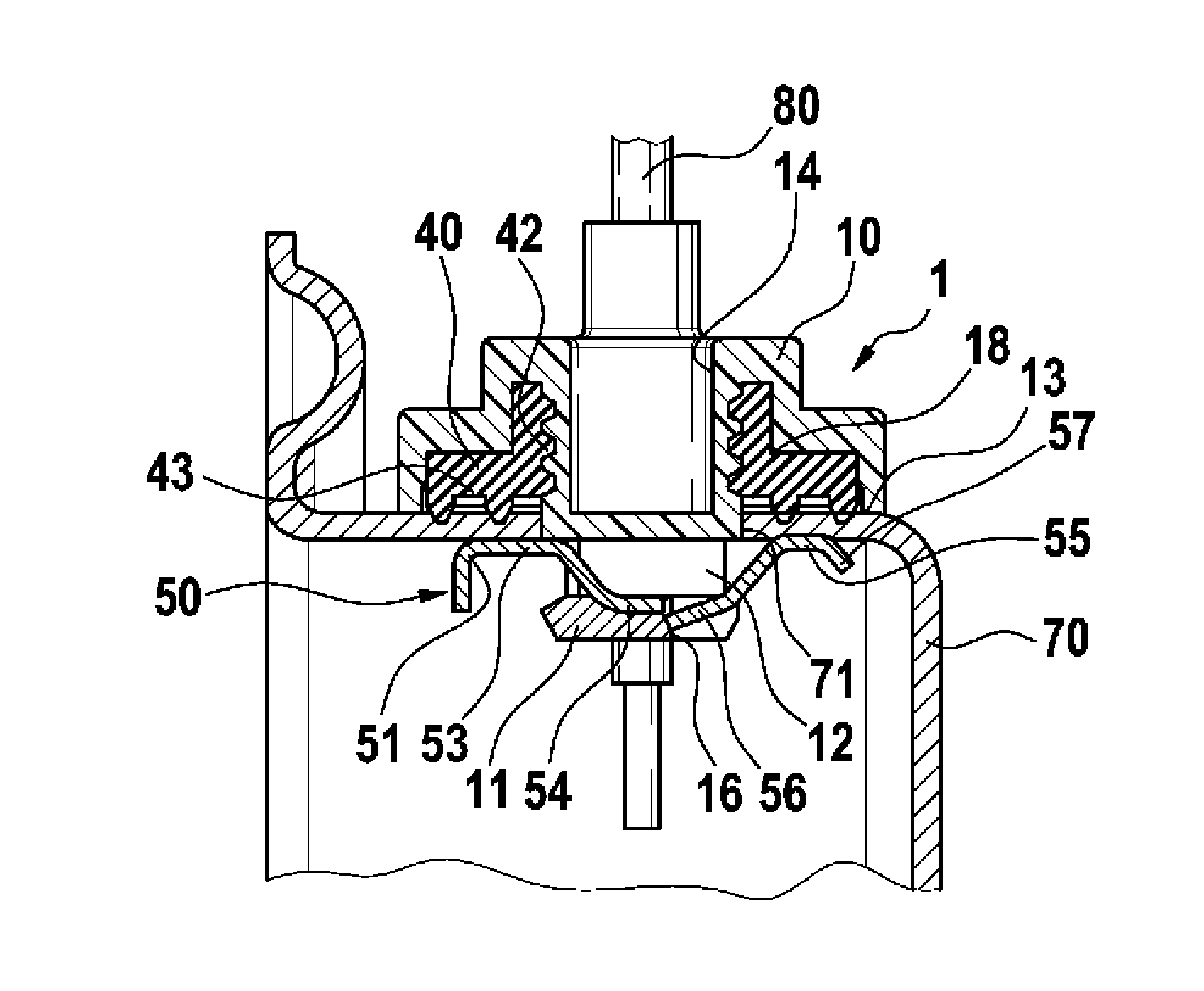

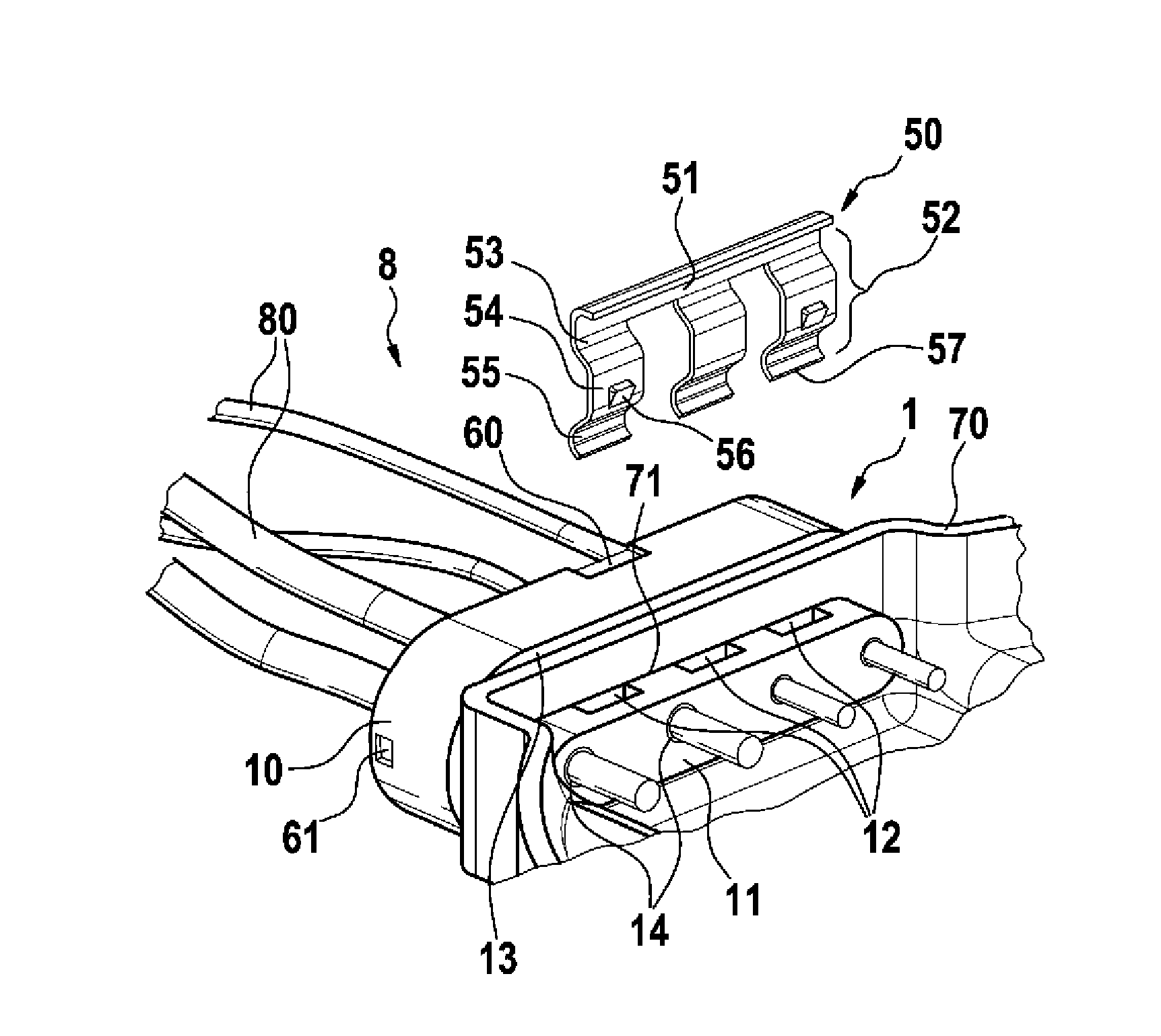

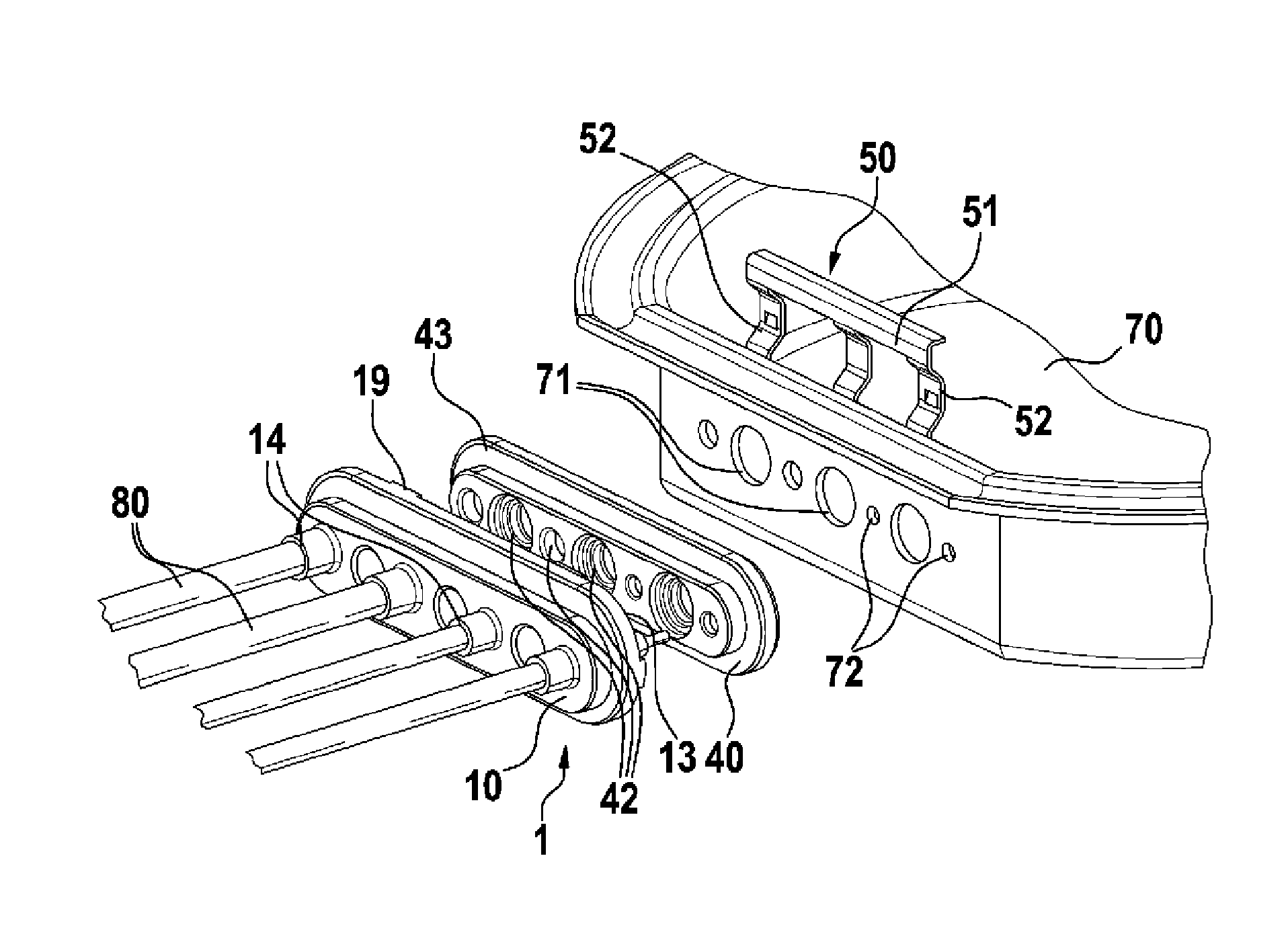

[0031] First refer to the following Figure 2 to Figure 8, illustrating a first variant of the fluid-tight motor connection plug 1 according to the invention according to two embodiments. The connecting plug 1 has a plug housing 10 by means of which the connecting plug can be fastened to a housing 70 of the electric machine 7 , for example to a pole housing 70 . At least one electrical line 80 or at least one cable 80 is guided through the connecting plug 1 into the interior of the motor, which is then electrically connected to the electrical conductors in the electrical machine 7 (see Figure 5 ). In this case, the electrical conductors 80 arranged on the connecting plug 1 form together with the connecting plug 1 a mass-produced cable 8 or cable bundle 8 .

[0032] The plug housing 10 is substantially square, has preferably rounded side walls and has a mounting section 11 on its front side, wherein a shoulder is formed on the plug housing 10 at the transition to the mountin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com