Installation device of helmet faceplate protective lens

A lens installation and panel technology, applied in the direction of installation, helmets, helmet covers, etc., can solve the problems of many errors and influencing factors, failure to meet automatic detection, convenience, intelligence, and insufficient fixation technology and methods of protective lens installation components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

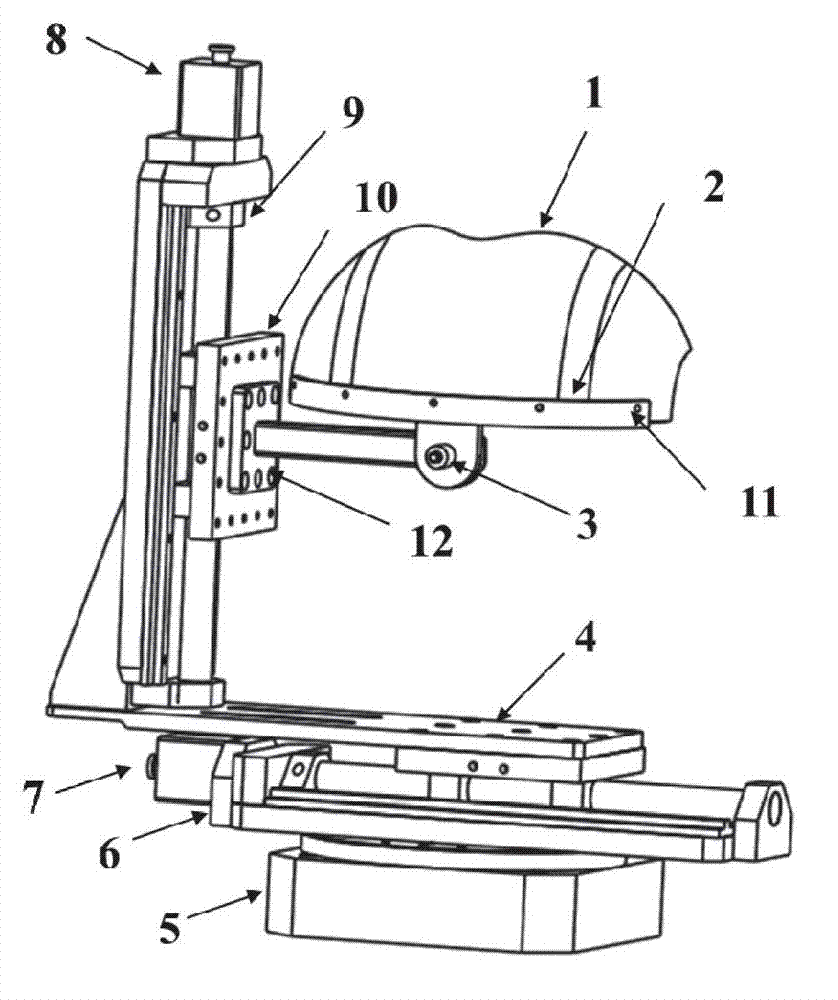

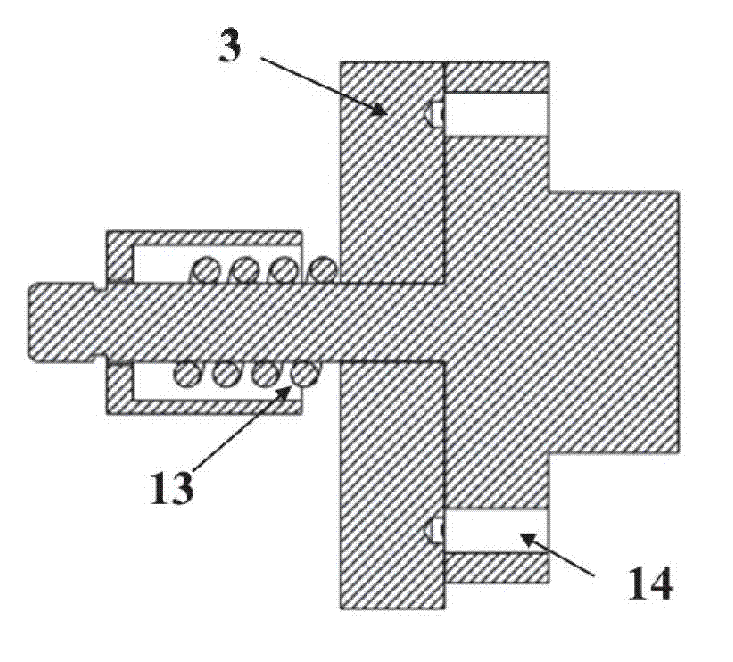

[0010] combine figure 1 and figure 2 The technical solution of the present invention is further described.

[0011] Such as figure 1 As shown, a helmet panel protective lens installation device of the present invention is composed of a lens fixing assembly and a console positioning assembly. The lens fixing assembly is composed of an accurate positioning assembly 2 and a rotatable flange 3. The console positioning assembly consists of a horizontal The displacement platform 6, the vertical displacement platform 9 and the turntable 5 are composed, the horizontal displacement platform 6 is driven by the horizontal stepping motor 7, and the vertical displacement platform 9 is driven by the vertical stepping motor 8. The protective lens 1 of the helmet panel is fixedly installed on the precise positioning component 2, and one end of the rotatable flange 3 is installed on the vertical translation platform 9 through the side bottom plate 10, and the vertical translation platform 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com