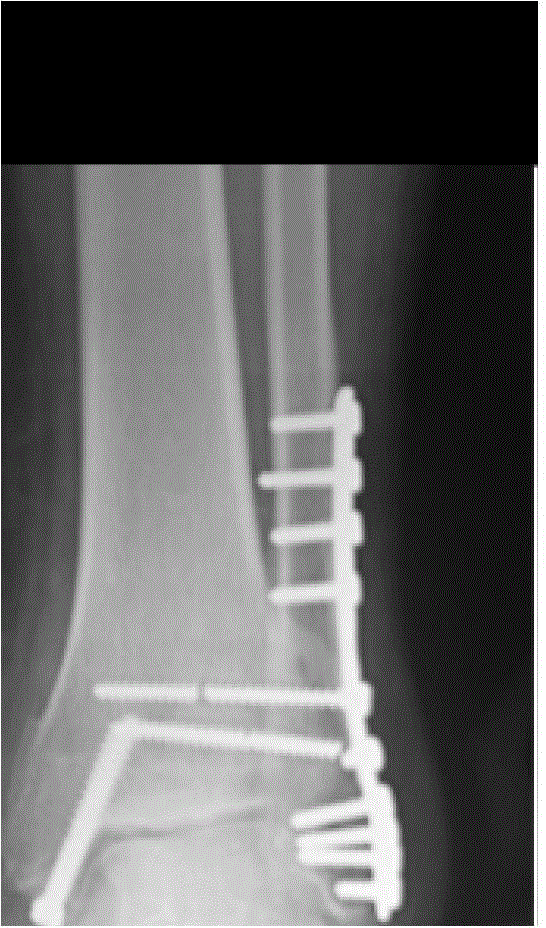

Telescopic tibiofibular syndesmosis fastening screw

A combined fixation and screw technology, applied in fixers, internal fixators, internal bone synthesis, etc., can solve problems such as broken nails, and achieve the effect of solving broken nails, convenient use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

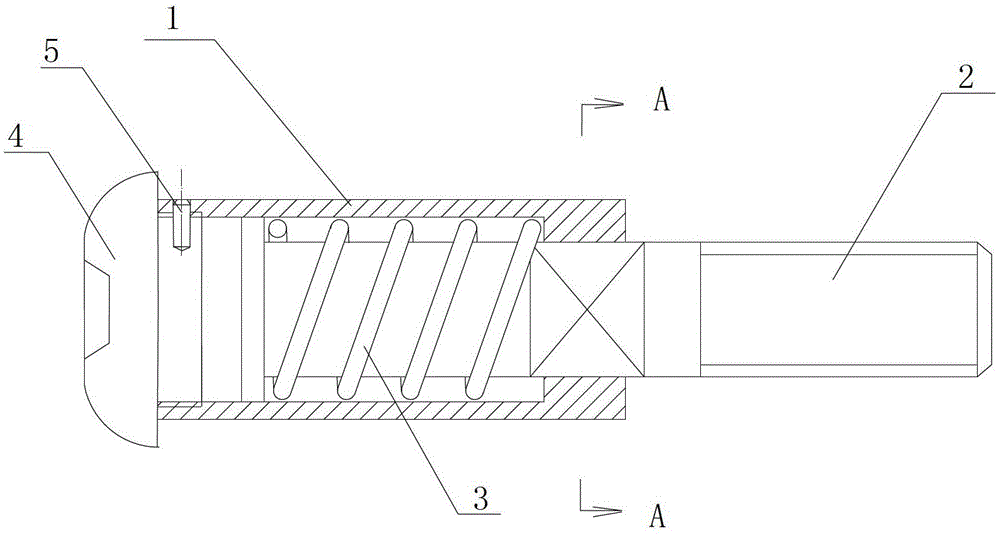

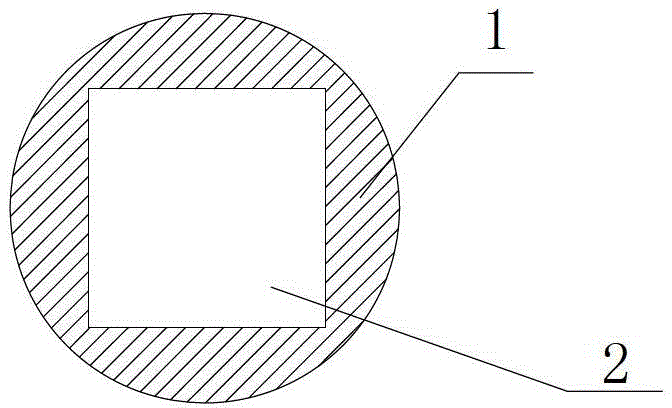

[0015] Example 1: see figure 2 , image 3 , a retractable lower tibiofibular syndesmosis screw, including a tube sleeve 1, a square hole is arranged under the tube sleeve 1, a screw 2 is arranged in the tube sleeve 1, the upper end of the screw 2 is a smooth section, and the middle part is a tube The square section matched with the square hole below the sleeve 1 has a screw at the bottom; a return spring 3 is arranged between the smooth section of the screw 2 and the pipe sleeve 1 . A nut 4 is fixedly connected with the pipe sleeve 1 at the top of the pipe sleeve 1, and the nut is larger than the pipe sleeve. The fixed connection between the nut 4 and the sleeve 1 is fixed pin connection.

Embodiment 2

[0016] Embodiment 2: A retractable lower tibiofibular syndesmosis screw, including a tube sleeve 1, a hexagonal hole is arranged below the tube sleeve 1, a screw 2 is arranged in the tube sleeve 1, the upper end of the screw 2 is a smooth section, and the middle part is It is a hexagonal section matched with the hexagonal hole below the pipe sleeve 1, and the lower part is a screw; a return spring 3 is arranged between the smooth section of the screw 2 and the pipe sleeve 1. The fixed connection between the nut 4 and the sleeve 1 is a reverse threaded connection. The rest is the same as the structure.

Embodiment 3

[0017] Embodiment 3: a retractable syndesmosis fixation screw, a retractable syndesmosis fixation screw, a retractable syndesmosis fixation screw, including a sleeve 1 and a tube sleeve 1 There is an octagonal hole at the bottom, and the screw 2 is arranged in the pipe sleeve 1. The upper end of the screw 2 is a smooth section, the middle part is an octagonal section matched with the octagonal hole below the pipe sleeve 1, and the lower part is a screw; the smooth section of the screw 2 A return spring 3 is provided between the pipe sleeve 1 . The fixed connection between the nut 4 and the sleeve 1 is the connection of the fixing screw. The rest is the same as the structure.

[0018] When in use, the hole is drilled first, because the turning nut of the present invention can drive the pipe sleeve to rotate, and the pipe sleeve drives the screw to rotate through the special-shaped hole. Larger than the sleeve, for this purpose, the syndesmosis can be fixed. The inferior tibi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com