Yam rail-cultivating method

A cultivation method and track technology, applied in the field of pollution-free and high-efficiency cultivation of yam, can solve the problems of reducing labor intensity, reducing workload, large one-time investment, etc., and achieving the effects of reducing labor intensity, reducing workload and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] First of all, it is necessary to determine the variety of cultivated yam, understand the length and diameter of the tubers, and the appropriate spacing between plants and rows.

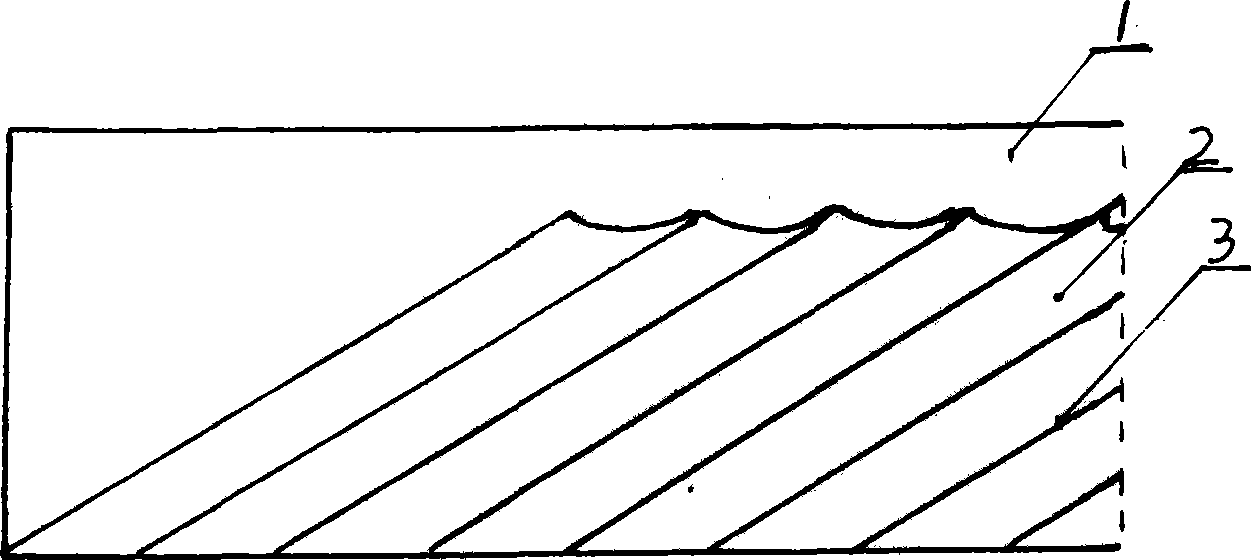

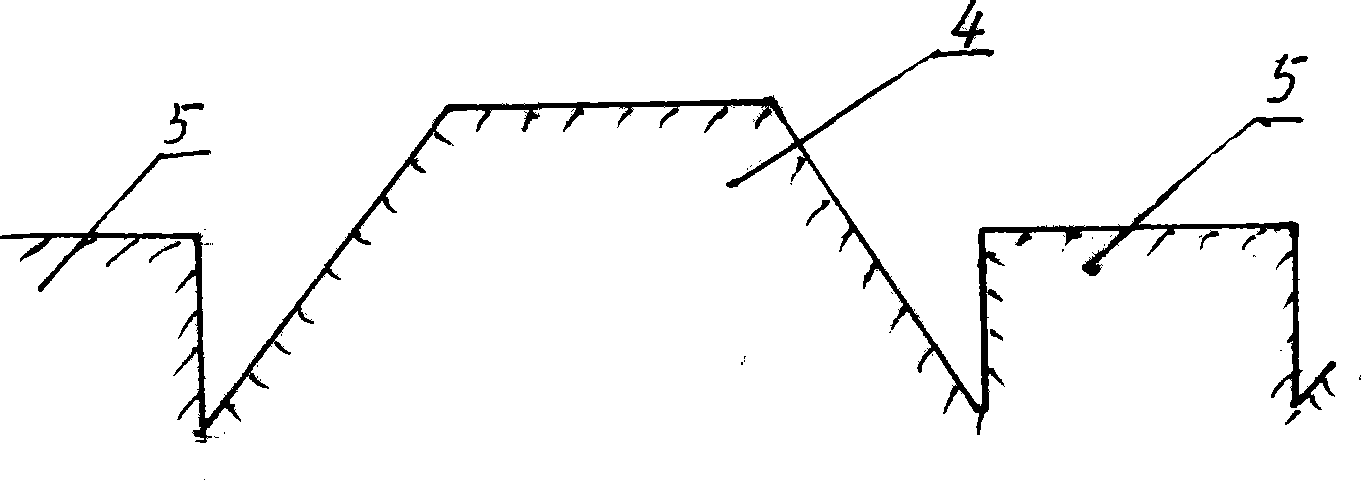

[0009] 1. The fabric used to make the track should be non-toxic, tough, corrosion-resistant, impermeable, small in elasticity, and low in price. figure 1 Shown in the figure: use two pieces of cloth, wide and narrow, the width of the wide cloth (1) is 20-100 cm, the material of the wide cloth (1) is on the bottom, and the material of the narrow cloth (2) is on the top, the two sides are aligned and overlapped, the ratio of the wide cloth (1) to The narrow cloth (2) is about 5-15 centimeters wide, and then a plurality of sewing lines (3) are sewed obliquely and parallel, the angle between the sewing lines (3) and the bottom edge of the cloth is between 20°-45°, each sewing line ( 3) The distance between them is about 10-25 cm. Narrow cloth is drawn flat certain length when sewing every sewing t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com