Processing method for titanium alloy inclined plane step holes

A processing method and step hole technology, applied in metal processing equipment, manufacturing tools, drilling/drilling equipment, etc., can solve problems such as no processing experience and cutting tool solutions, achieve technical level improvement, ensure design requirements, and far-reaching economy benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A processing method capable of realizing stepped holes on titanium alloy slopes and its special tool breaks through the technical bottleneck in the processing of stepped holes on titanium alloy slopes, ensures the smooth development of fan shafts, and provides valuable experience for the processing of similar parts in the future.

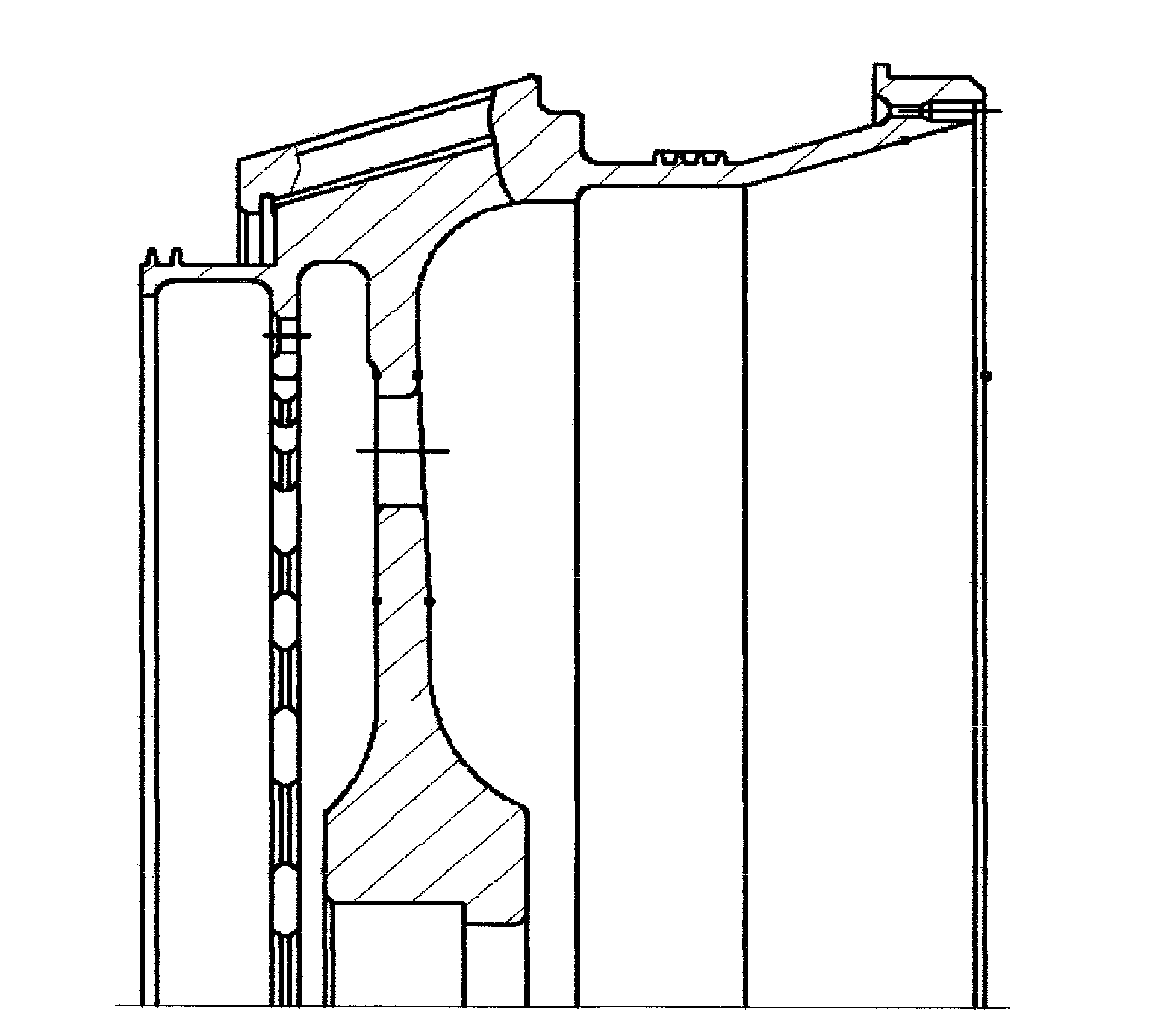

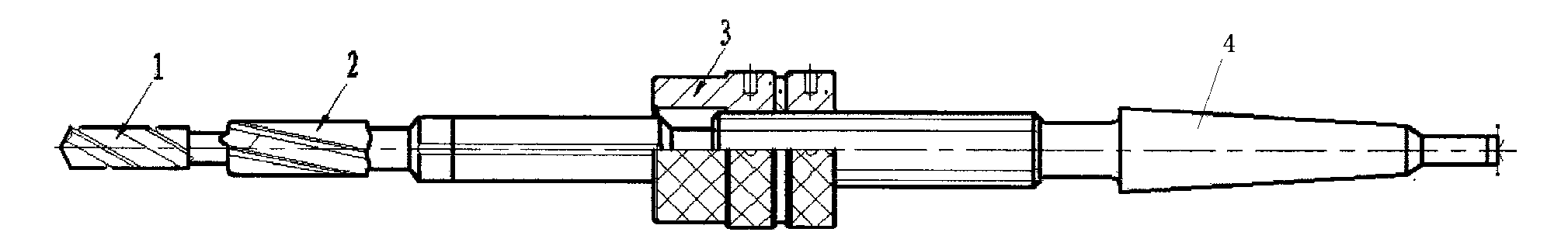

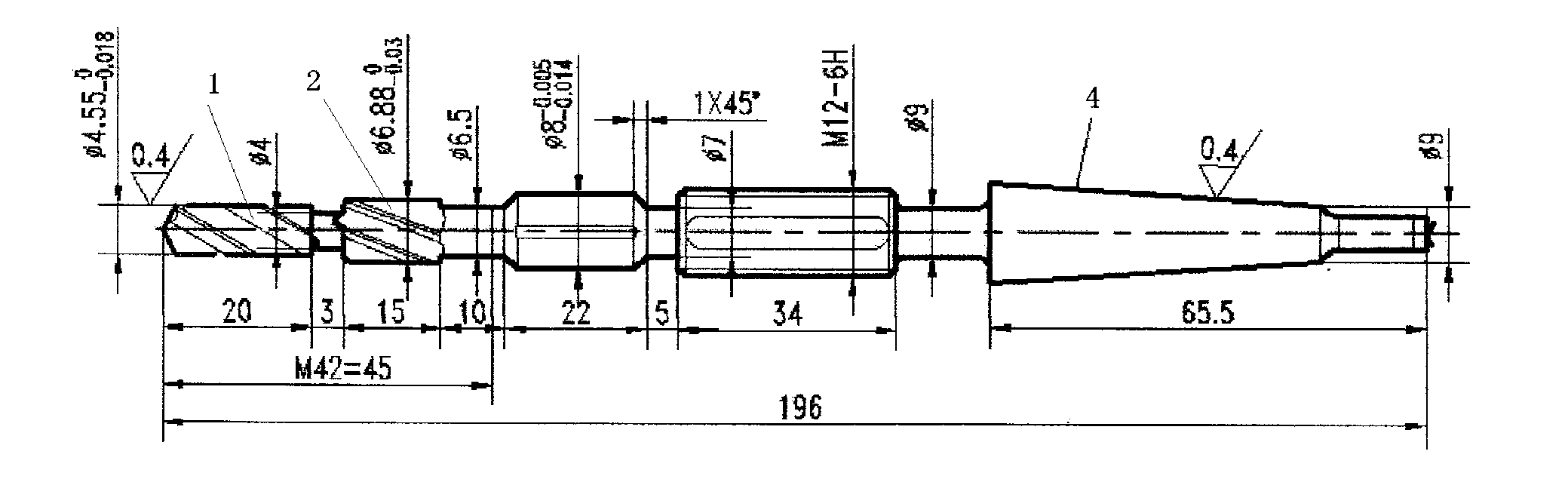

[0024] A method for processing a titanium alloy inclined-plane step hole, which uses a special composite processing tool, and the composite processing tool is a coaxial segmented integrated overall structure tool, according to the distance from the tool handle (4) from far to near The following three-section structures are arranged in series in sequence: the drill part (1), the reamer part (2), and the nut (3);

[0025] The specific requirements for the processing method of the titanium alloy inclined-plane step hole are:

[0026] ①Adjust the nut of the compound reaming drill: adjust it to the position that meets the requirements of the step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com