A numerical control finish turning method for annular ω groove of titanium alloy thin-walled disk ring

A processing method and technology of thin-walled discs, which are applied in metal processing equipment, workpieces, turning equipment, etc., can solve the problems of not meeting the size and technical requirements of parts, affecting the processing efficiency and processing quality of parts, and difficult to guarantee the size and technical conditions. , to achieve the effect of solving the technical requirements of processing accuracy and efficient processing, solving the low processing efficiency, and improving the research and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

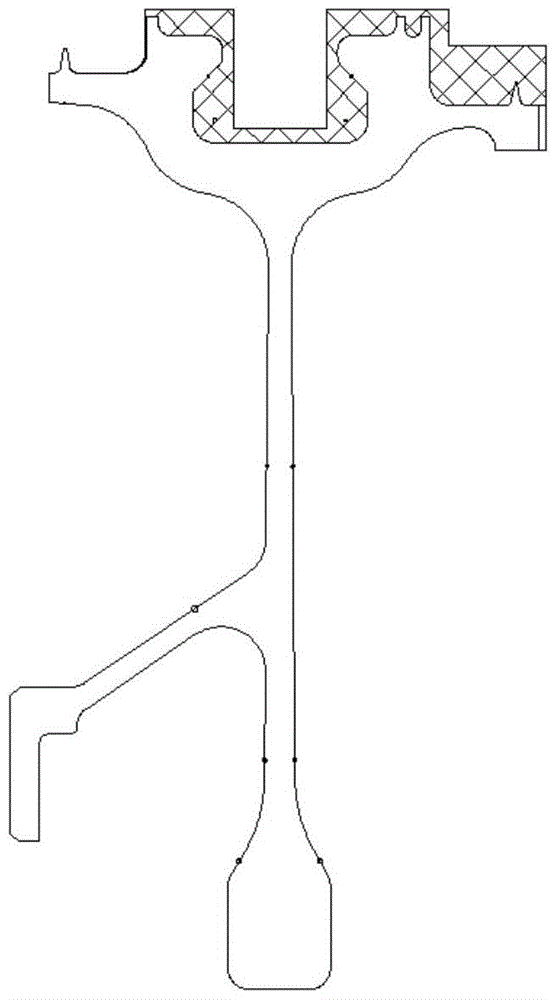

[0032] The turning process of the annular Ω groove of the titanium alloy thin-walled disc ring is divided into three processes: rough turning, semi-finishing turning and finishing turning, and the finishing turning process of the annular Ω groove of the titanium alloy thin-walled disc ring is divided into rough machining and semi-finishing There are three stages of finishing and finishing. This embodiment is aimed at the numerical control finishing machining of the annular Ω groove of the titanium alloy thin-walled disk ring, and implements the method on the numerical control vertical lathe.

[0033] A kind of numerical control finish turning processing method of annular Ω groove of titanium alloy thin-walled disk ring, Figure 6 shown, including the following steps:

[0034] Step 1: Determine the margin of each processing stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com