Machining method of parallel membrane disc coupling

A processing method and coupling technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as tools are prone to vibration, processing methods are not suitable, and affect the surface state of parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The invention provides a processing method of a parallel diaphragm disc coupling, which is characterized in that: the parallel diaphragm disc coupling is composed of two diaphragm discs and a central shaft, the axial thickness of the diaphragm discs is small, the radial overhang is long, and the two A deep cavity with a height of about 70mm is formed between two parallel diaphragm discs, and the length of the deep cavity exceeds 130mm. Traditional tools and clamping schemes are difficult to process, so a new processing method is created for processing; in the processing method of parallel diaphragm couplings, the tool Design: half of the length of the tool enters the deep cavity of the part for processing, and half of it is used for machine tool clamping to obtain sufficient tool rigidity, to ensure that the tool does not vibrate during the process, and to avoid the limitation of the machining stroke caused by the tool being too long; the CNC machining tool and the machin...

Embodiment 2

[0024] The lathe processing method of the parallel diaphragm coupling is described from four aspects: part structure, tool selection, fixture design, and parameter selection.

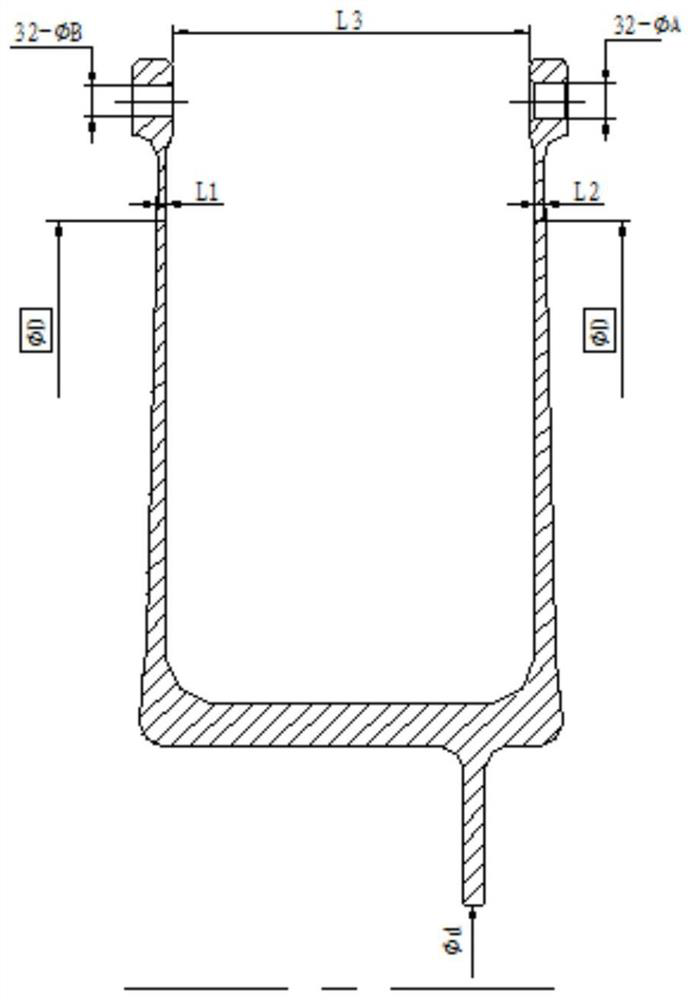

[0025] Part structure as attached figure 1 As shown, the wall thickness of the diaphragm of the parallel diaphragm coupling is 1.84mm, and the overhang is 145.5mm, which is a typical thin-walled structure. A deep cavity of 145.5mm deep and 73mm wide is formed in the middle of the parallel diaphragm disc.

[0026] The overall processing plan of the part is: processing the threaded hole → processing the deep cavity of the diaphragm → processing the outer surface of the diaphragm → processing the round hole

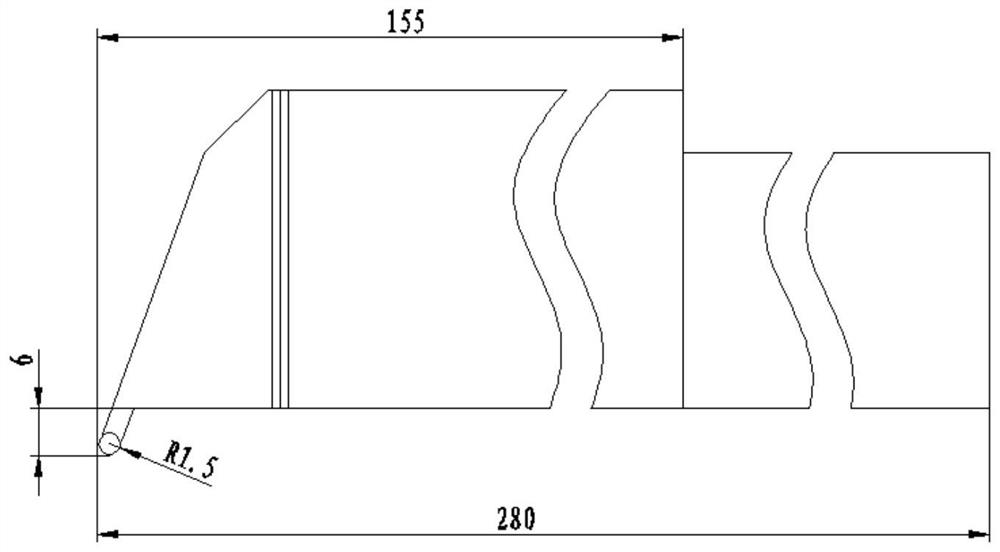

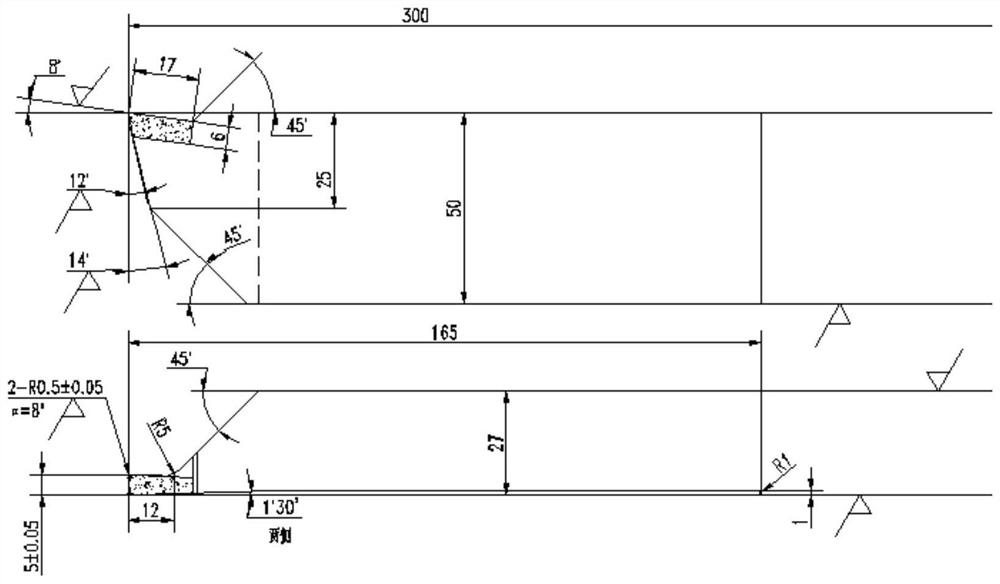

[0027] Tool selection is mainly based on reducing tool vibration. Figure 4 of knives. The length is 300mm, which meets the length requirement of deep cavity machining, but too long tool overhang will lead to insufficient tool rigidity and easy tool vibration during processing, so the tool thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com