Metal composite molecular sieve with multiple channels and preparation method thereof

A metal composite and molecular sieve technology, applied in chemical instruments and methods, other chemical processes, tobacco, etc., can solve the problems of clogged channels, shedding, etc., achieve strong adsorption capacity, meet the processing technology, and have no effect on the sensory quality of cigarettes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Weigh 25g of ferric nitrate dissolved in 150ml of ethanol solution, add 40g of silica gel with a particle size of 100-150 mesh, stir for a while until the ethanol evaporates, dry the powder in an oven at 60°C, and then place it in a tube furnace at 250°C , under a nitrogen atmosphere for 12 hours, the iron oxide infused composite material Fe x o y SiO 2 .

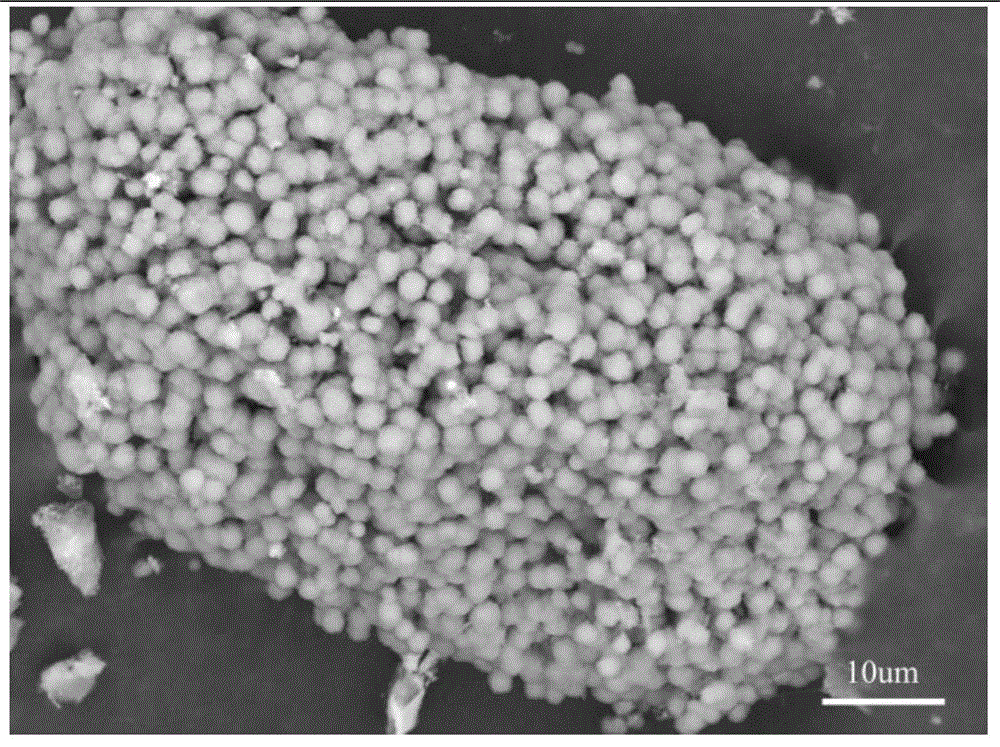

[0032] Composite Fe infused with iron oxide x o y SiO 2 Add to NaOH, TPAOH, water (molar ratio: 10NaOH:36TPAOH:4200H 2 O) In a uniformly mixed solution, stir at room temperature for 2 hours, put it into a hydrothermal reaction kettle, react at 180°C for 24 hours, take it out, cool it, wash it, dry it, and finally calcinate it in a muffle furnace at 550°C for 6 hours. The specific surface area obtained is 310.5m 2 / g, bulk molecular sieve material 1 with various channels modified by iron oxide, its scanned picture is as follows figure 1 shown. figure 1 The overall block molecular sieve material is composed of...

Embodiment 2

[0038] Weigh 3.6g of cerium nitrate and dissolve it in 20ml of ethanol solution, add 6.0g of silica gel with a particle size of 60-100 mesh, stir for a period of time until the ethanol evaporates, dry the powder in an oven at 60°C, and then place it in a muffle furnace , 350°C for 6h, and the composite material CeO infused with cerium oxide was obtained. 2 SiO 2 .

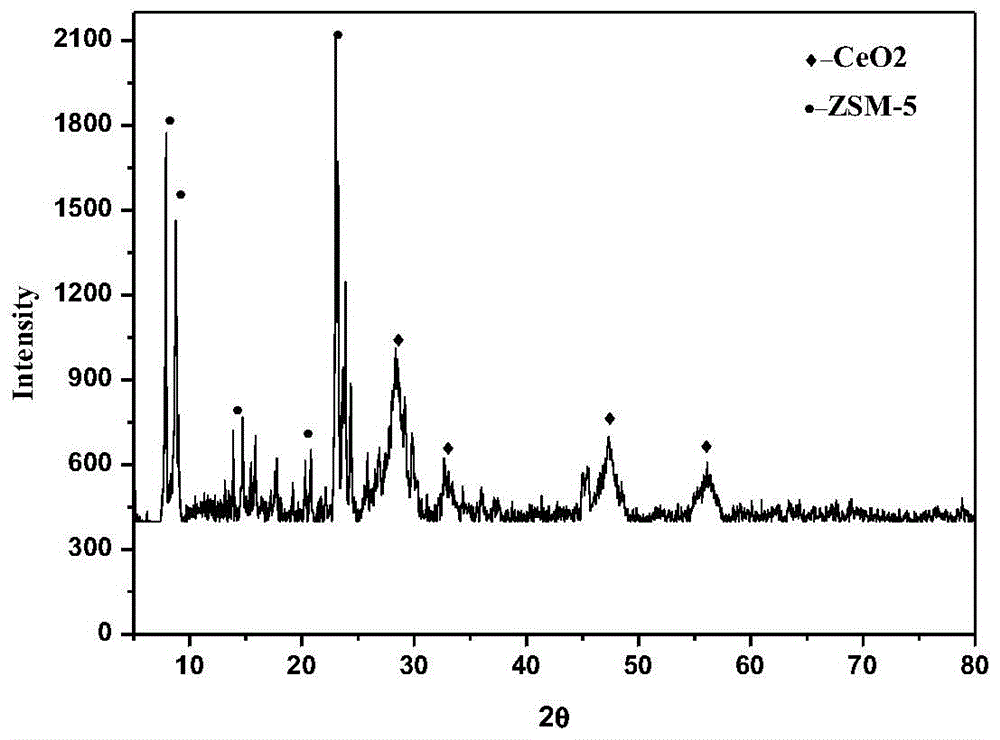

[0039] Composite material CeO infused with cerium oxide 2 SiO 2 Add to NaOH, TPAOH, water mixed solution (molar ratio: 10NaOH:36TPAOH:4200H 2 O), stirred at room temperature for 2 hours, put into a hydrothermal reaction kettle, reacted at 160°C for 30 hours, took it out, cooled, washed, dried, and finally calcined in a muffle furnace at 650°C for 4 hours to obtain a specific surface area of 317.2m 2 / g, bulk molecular sieve material 2 with a variety of channel metal cerium modification, its XRD is as follows figure 2 shown. figure 2 Shown in the middle are ZSM-5 and CeO 2 The XRD diffraction peaks are the...

Embodiment 3

[0045] Weigh 2.2g of ferric nitrate and 0.8g of nickel nitrate and dissolve in 20ml of ethanol solution, add 6.0g of silica gel with a particle size of 100-10 mesh, stir for a period of time until the ethanol evaporates to dryness, dry the powder in an oven at 60°C, and then place Burn in a muffle furnace at 300°C for 12 hours to obtain NiFe 2 o 4 Infused Composite NiFe 2 o 4 SiO 2 .

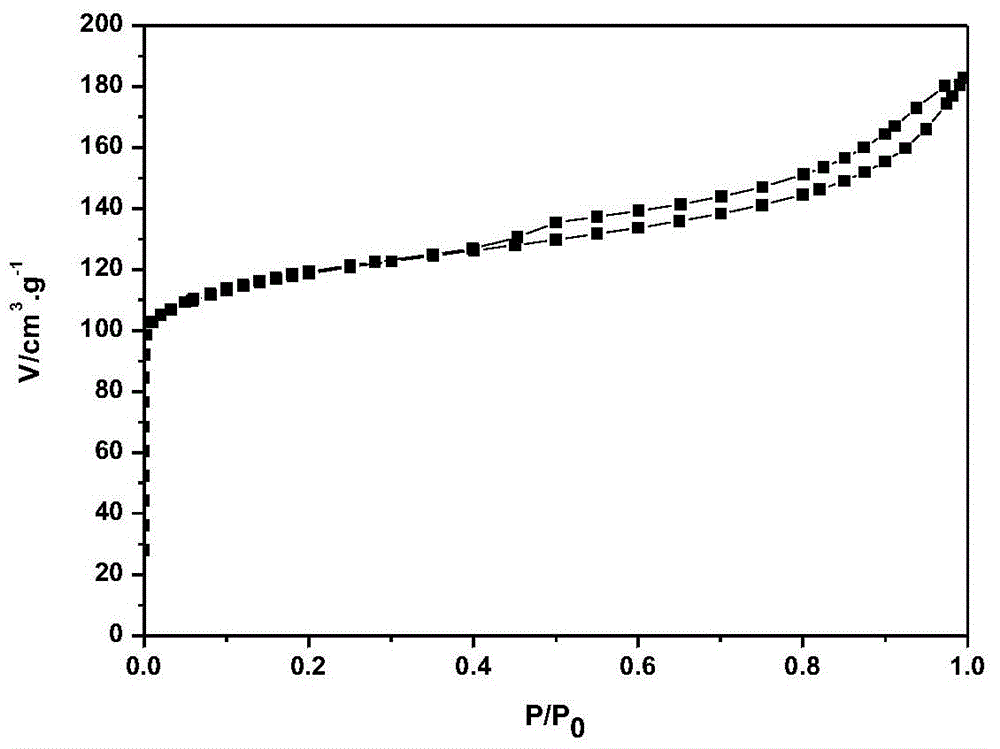

[0046] NiFe 2 o 4 Infused Composite NiFe 2 o 4 SiO 2 Add to NaOH, TPAOH, CTAB and water (molar ratio: 10NaOH:36TPAOH:5CTAB:4200H 2 O) In a uniformly mixed solution, stir at room temperature for 2 hours, put it into a hydrothermal reaction kettle, react at 180°C for 48 hours, take it out, cool it, wash it, dry it, and finally calcinate it in a muffle furnace at 550°C for 8 hours. The specific surface area obtained is 351.9m 2 / g, composite metal NiFe with various channels 2 o 4 Modified bulk molecular sieve material 3, its adsorption-desorption curve is as follows image 3 shown. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com