Micro-mesoporous carbon-carbon composite material and preparation method thereof

A carbon composite material and mesoporous carbon technology, applied in the direction of carbon preparation/purification, carbon compounds, chemical instruments and methods, etc., can solve the problem of reducing the hazards of cigarettes, easy to block micropore channels, and difficult to achieve comprehensive reduction of harmful components, etc. problem, achieve the effect that the reaction conditions are easy to control, the effect is reduced, and the cost is low

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

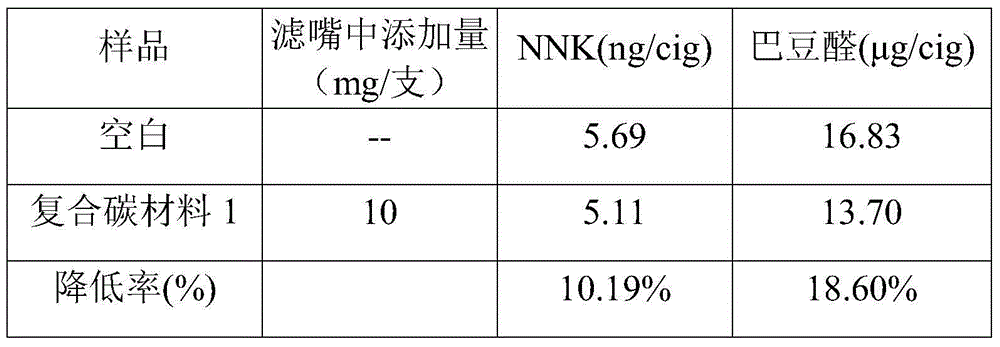

Embodiment 1

[0025] Weigh 61.1g of phenol into a four-neck flask, dissolve it at 43°C, add 13.0g of NaOH, stir for 10 minutes, add 105.4g of formaldehyde solution (mass fraction 37%) dropwise with a constant pressure funnel, continue to heat up, when After the temperature reaches 70-75°C, react for 1 hour. After the reaction, adjust the pH value to 7.0 with HCl, vacuum dehydrate at 50°C, and finally dissolve the product in ethanol (20wt% ethanol solution) to prepare the methyl phenolic resin precursor body.

[0026] After crushing the tobacco stems, take 40-100 mesh particles, mix them with KOH at a weight ratio of 1:1, add deionized water and fully impregnate them for 16 hours, then vacuum dry them at 100°C for 2 hours, and then calcinate them at 800°C in a nitrogen atmosphere. Get activated carbon.

[0027] Weigh 10g of F127 and dissolve it in 100g of ethanol to form a clear solution at 40°C, add 50g of resole phenolic resin precursor (20wt% ethanol solution), and continue stirring for ...

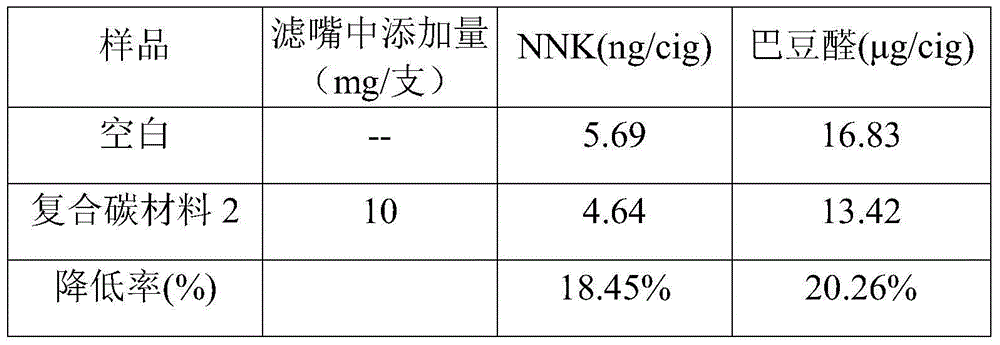

Embodiment 2

[0032] After weighing 10g of F127 and dissolving it in 100g of ethanol to form a clear solution at 40°C, add 50g of the resole phenolic resin (20wt% ethanol solution) prepared in Example 1 and continue stirring for 2h. Add 28g of activated carbon (same as Example 1) and continue to stir until the ethanol volatilizes, and then further thermally agglomerate in a 100 degree oven for 24h. Then, it was calcined at 350°C for 3h and 900°C for 2h under the protection of nitrogen to obtain a micro-meso composite carbon material 2 with a specific surface area of 1076m2 / g, in which the mesoporous carbon content was 20wt%.

[0033] The micro-media composite carbon material 2 is added to the cigarette holder rod, specifically, the binary composite filter rod is composed of acetate fiber segments and acetate fiber segments added with the micro-media composite carbon material 2, and the micro-media composite The cellulose acetate section of carbon material 2 is to disperse the micro-media ...

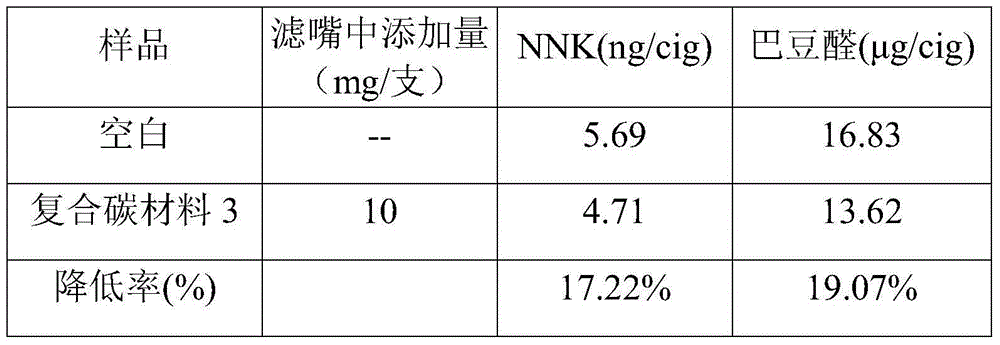

Embodiment 3

[0037] Weigh 10g of F127 and dissolve it in 150g of ethanol to form a clear solution at 40°C, add 50g of resole phenolic resin (20wt% ethanol solution), and continue stirring for 2h. Add 16g of activated carbon (same as in Example 1) and continue to stir until the ethanol volatilizes, and then further thermally agglomerate in a 100 degree oven for 24 hours. Then, it was calcined at 350°C for 3h and 900°C for 2h under the protection of nitrogen to obtain a micro-medium composite carbon material 3 with a specific surface area of 943m2 / g, in which the content of mesoporous carbon was 30wt%.

[0038] The micro-media composite carbon material 3 is added to the cigarette holder rod, specifically, the binary composite filter rod is composed of acetate fiber segments and acetate fiber segments added with the micro-media composite carbon material 3, and the micro-media composite The cellulose acetate section of the carbon material 3 is to uniformly disperse the micro-media composite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com