Metal pillared montmorillonite coated mesoporous silica composite material and preparation method thereof

A composite material and metal pillar technology, which is applied in the field of metal pillared montmorillonite-coated mesoporous silicon composite material and its preparation, can solve the problems of unsatisfactory adsorption effect, low specific surface area, small interlayer spacing, etc., and achieves reaction conditions The effect of easy control, simple process and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 242.4 grams of Fe (NO 3 ) 3 .9H 2 O, add water to dissolve, stir at room temperature, slowly add 63.6 g of anhydrous sodium carbonate powder, add water to dilute to 2000 mL, continue stirring for 2 hours, and age in a constant temperature water bath at 60 ° C for 24 hours to obtain a brown transparent iron proppant .

[0023] Weigh 100 grams of commercially available purified montmorillonite, add 2000 mL of water to make a suspension, add 350 ml of iron proppant dropwise under constant temperature stirring at 60 °C, react for another 2 hours, and then age at 60 °C for 24 hours , and then washed, centrifuged, and dried to prepare iron-pillared montmorillonite.

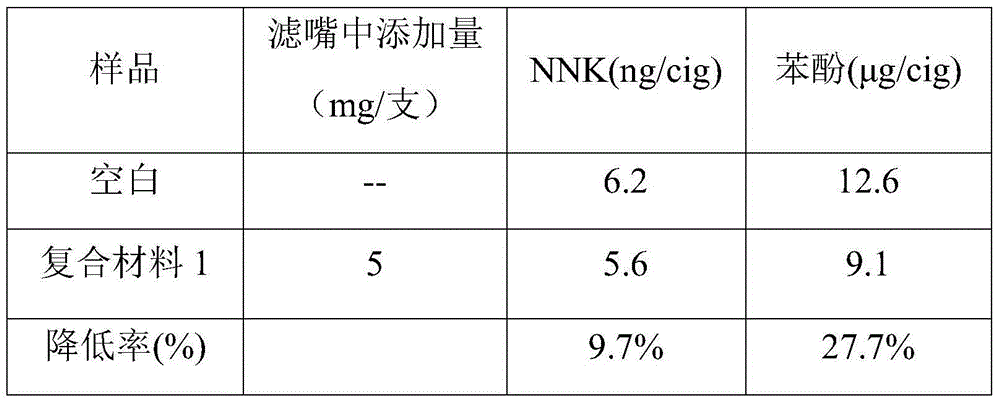

[0024] Weigh 200g of iron-pillared montmorillonite, add water to make a 30wt% suspension, add 1800g of 40-80 mesh mesoporous silicon, stir evenly, and dry at 100°C to obtain iron-pillared montmorillonite-coated mesoporous silicon Composites 1. The obtained composite material 1 was added to the filter t...

Embodiment 2

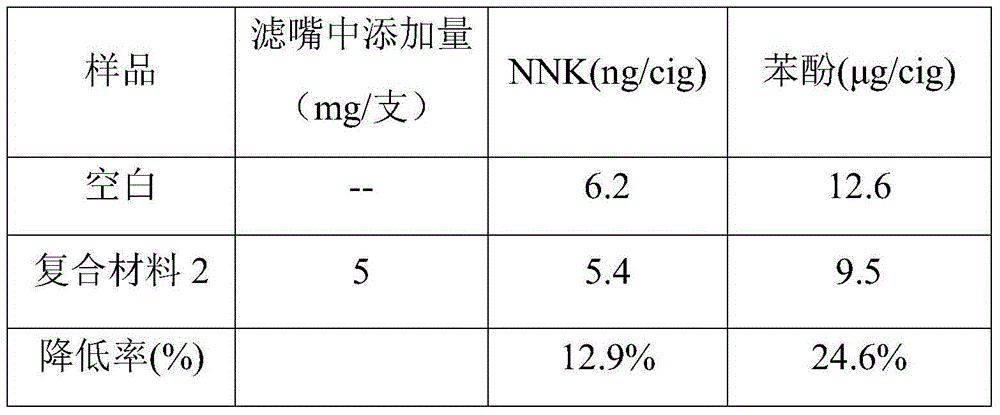

[0029] Weigh 400g of iron-pillared montmorillonite in Example 1, add water to form a 30wt% suspension, add 1600g of 40-80 mesh mesoporous silicon, stir evenly, and dry at 100°C to obtain iron-pillared montmorillonite Composite material 2 coated with mesoporous silicon. The composite material 2 was added to the filter according to the method of Example 1 to prepare a binary composite filter. The test results are shown in Table 2.

[0030] Table 2:

[0031]

Embodiment 3

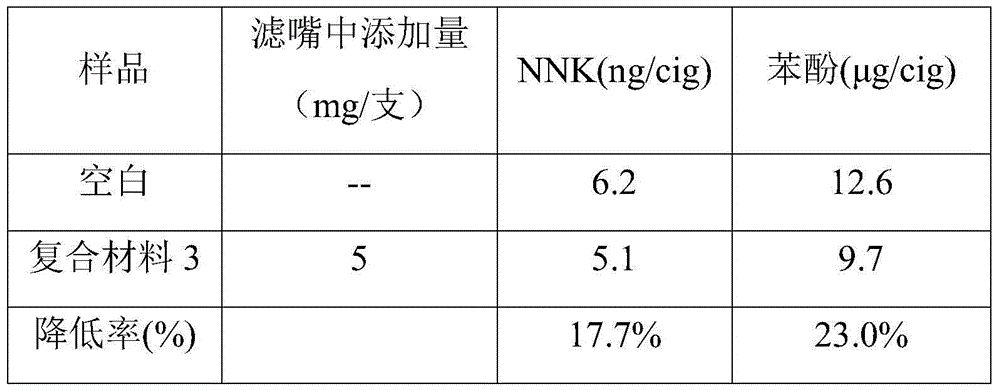

[0033] Weigh 600g of the iron-pillared montmorillonite of Example 1, add water to form a 30wt% suspension, add 1400g of 40-80 mesh mesoporous silicon, stir evenly, and dry at 100°C to obtain the iron-pillared montmorillonite package Composite materials coated with mesoporous silicon 3. The test results are shown in Table 3.

[0034] table 3:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com