Stainless steel processing oil and preparation method thereof

A technology for processing oil and stainless steel, which is applied in the field of steel processing oil, can solve the problems of increasing the cost and price of oil products, increasing extreme pressure agents, etc., to achieve cost advantages, improve lubrication performance, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

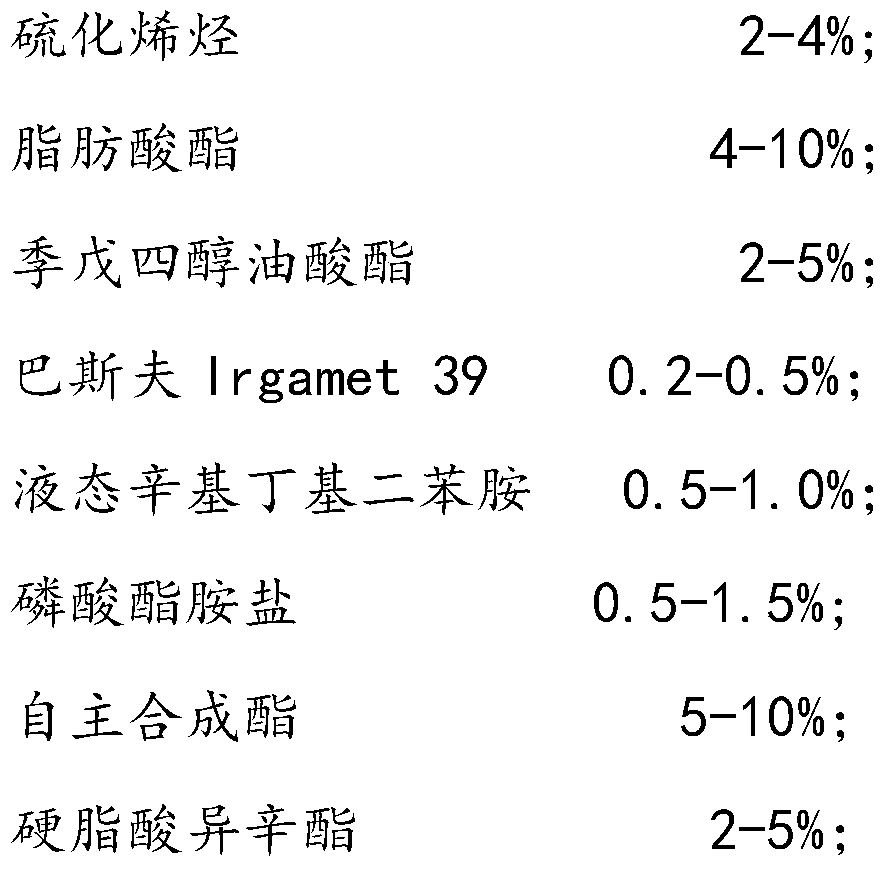

Method used

Image

Examples

Embodiment 1

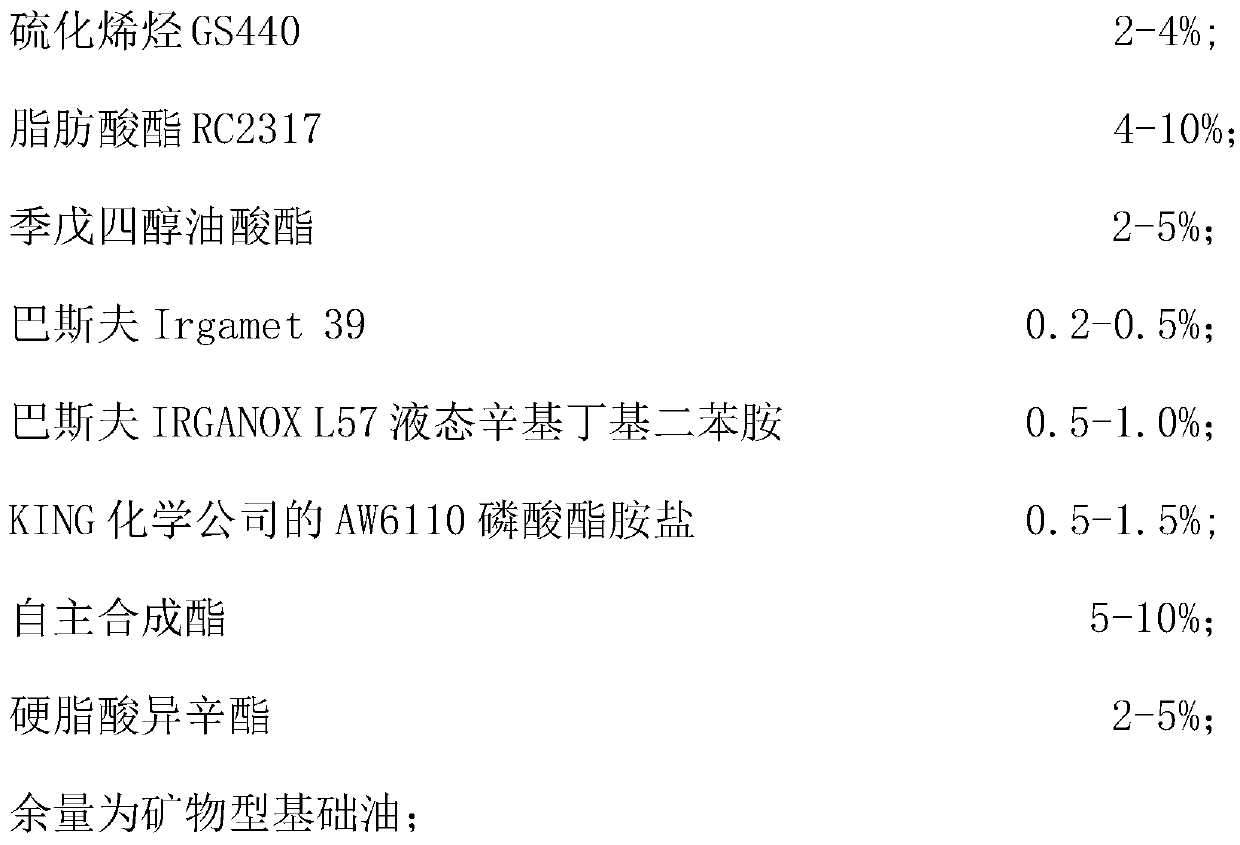

[0032] Addition of ①sulfurized olefin GS440 2%, ②fatty acid ester RC2317 6%, ③pentaerythritol oleate 2%, ④BASF Irgamet 39 0.2%, ⑤BASF IRGANOX L57 liquid octylbutyl diphenylamine 0.5%, ⑥AW6110 phosphate amine salt 0.5%, ⑦self-synthesized ester 8%, ⑧ isooctyl stearate 2%, ⑨mineral base oil 78.8%.

[0033] The method for preparing stainless steel processing oil is characterized in that it comprises the following steps:

[0034] 1) Prepare materials for stainless steel processing oil according to the above ratio;

[0035] 2) Put the mineral base oil into the reactor first, then add the sulfurized olefin, fatty acid ester and pentaerythritol oleate in sequence, and stir while heating, the temperature does not exceed 100°C, and stir for 30 minutes;

[0036] 3) Add BASF Irgamet 39, liquid octyl butyl diphenylamine, phosphate amine salt, self-synthesized ester, and isooctyl stearate into the reaction kettle in sequence, continue heating, the temperature does not exceed 100 ℃, and stir for 1 h...

Embodiment 2

[0043] Add sulfurized olefin GS440 4%, fatty acid ester RC2317 4%, pentaerythritol oleate 4%, BASF Irgamet 39 0.5%, BASF IRGANOX L57 liquid octylbutyl diphenylamine 0.5%, AW6110 phosphate amine salt 1%, self-synthesized Esters 5%, isooctyl stearate 3%, base oil 78%.

Embodiment 3

[0045] Add sulfurized olefin GS440 3%, fatty acid ester RC2317 10%, pentaerythritol oleate 5%, BASF Irgamet 39 0.5%, BASF IRGANOX L57 liquid octyl butyl diphenylamine 1%, AW6110 phosphate amine salt 1.5%, self-synthesized Ester 10%, isooctyl stearate 5%, base oil 64%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com