Additive for reducing ammonia release quantity in cigarette smoke and preparation method thereof

A technology for cigarette smoke and additives, which is applied to chemical instruments and methods, tobacco, smoke oil filter elements, etc., can solve the problem of insignificant selective ammonia reduction effect, and achieves a sensory quality with no effect, low cost, and reduced release. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 150g CaCl 2 Dissolve in an appropriate amount of deionized water, stir to form a homogeneous solution; the CaCl in the complex 2 The mass percentage is 5%, and the specific surface area of 40-80 mesh is about 300m 2 / g of mesoporous silicon 2850g, then stir evenly, and let the CaCl 2 fully loaded on the outer surface and internal pores of the mesoporous silicon, then placed in an oven at 110° C. for 24 hours, and cooled to room temperature to obtain the functionalized mesoporous silicon material 1 .

[0023] Table 1 Effect of functionalized mesoporous silicon additives on the release of gas-phase ammonia and particulate-phase ammonia in mainstream cigarette smoke

[0024]

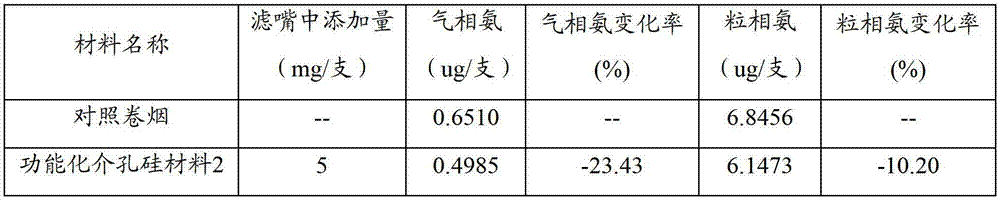

Embodiment 2

[0026] Weigh out 300 CaCl 2 Dissolve in an appropriate amount of deionized water, stir to form a homogeneous solution; the CaCl in the complex 2 The mass percentage is 10%, and the specific surface area of 40-80 mesh is about 300m 2 / g of mesoporous silicon 2700g, then stir evenly, and let the CaCl 2 Fully loaded on the outer surface and internal pores of mesoporous silicon, then placed in an oven at 110° C. for 24 hours, and cooled to room temperature to obtain functionalized mesoporous silicon material 2 .

[0027] Table 2 Effects of functionalized mesoporous silicon additives on the release of gas-phase ammonia and particulate-phase ammonia in mainstream cigarette smoke

[0028]

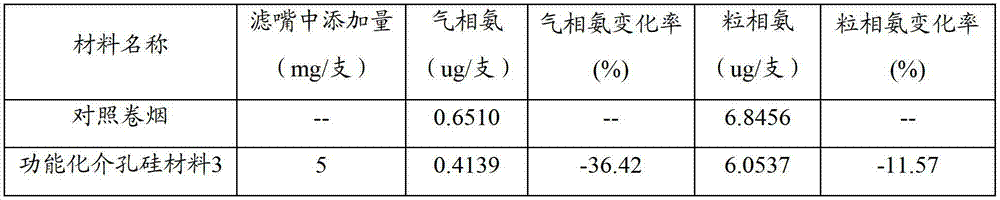

Embodiment 3

[0030] Weigh 450g of CaCl 2 Dissolve in 3L of deionized water, stir to form a homogeneous solution; CaCl in the complex 2 The mass percentage is 15%, and the specific surface area of 40-80 mesh is about 300m 2 / g of mesoporous silicon 2550g, then stir evenly, and place it at room temperature for 12 hours to let CaCl 2 Fully loaded on the outer surface and internal pores of mesoporous silicon, then placed in an oven at 110° C. for 24 hours, and cooled to room temperature to obtain functionalized mesoporous silicon material 3 .

[0031] Table 3 Effect of functionalized mesoporous silicon additives on the release of gas phase ammonia and particulate phase ammonia in mainstream cigarette smoke

[0032]

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com